Collaborative robot joint structure

A technology of robot joints and encoders, which is applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems that the control mechanism cannot quickly and accurately act on the servo mechanism, cannot realize mechatronics, and cannot accurately control, etc., to achieve the position of the joint structure The effect of reasonable layout, realization of mechatronics and simplification of internal mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

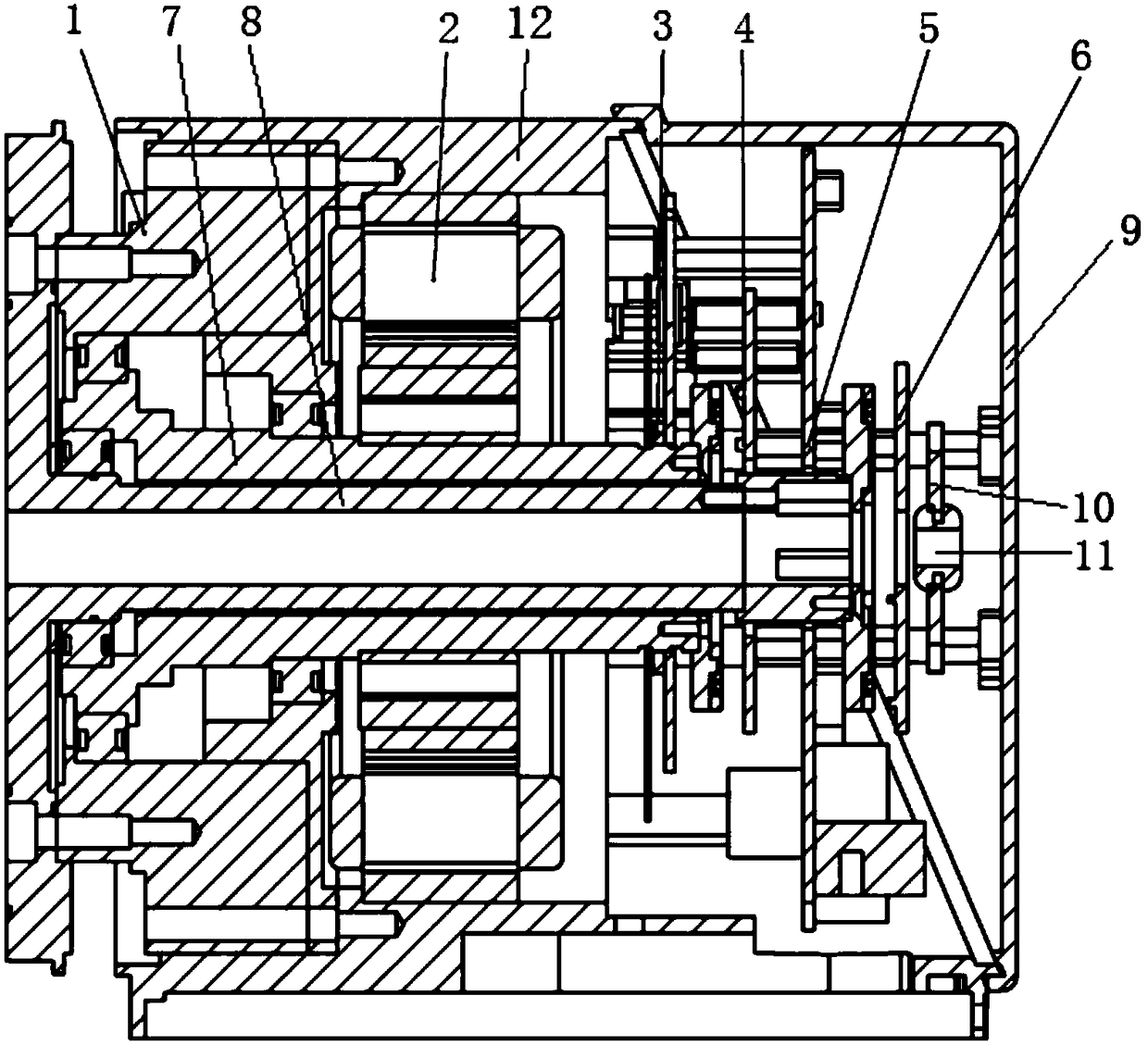

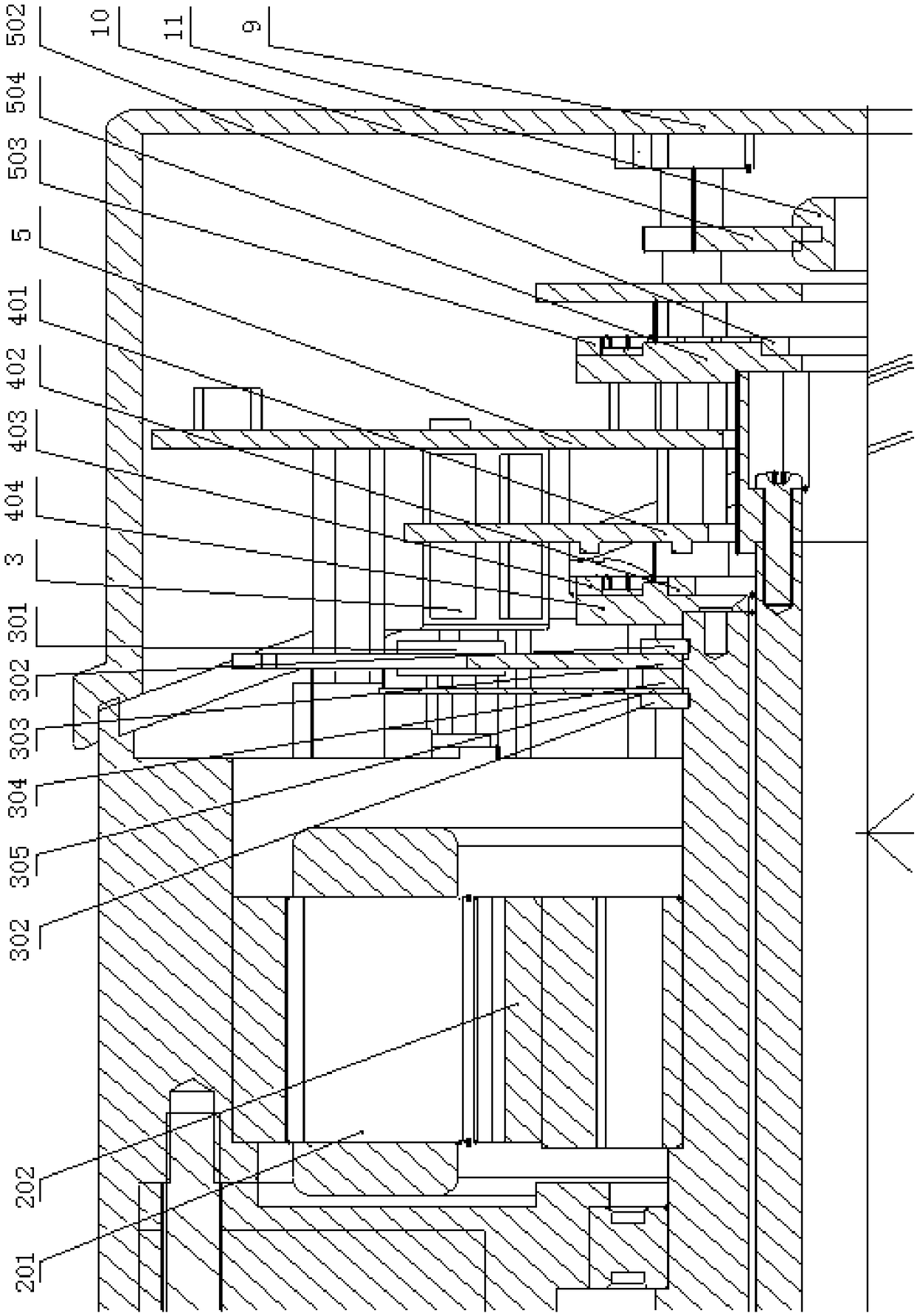

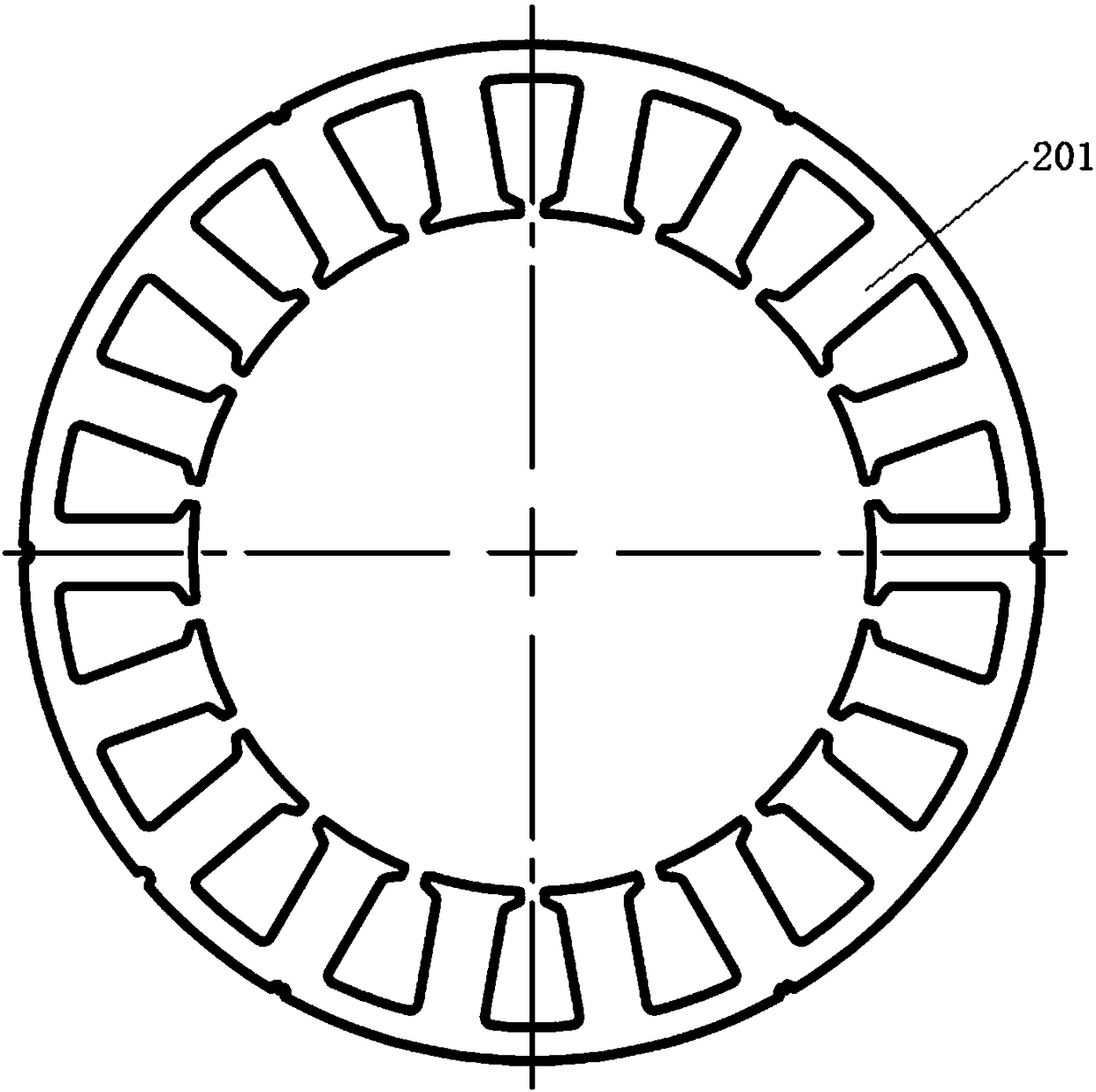

[0025] A collaborative robot joint, such as figure 1 , 2 As shown, it includes a housing 12 and a servo motor 2 disposed in the housing 12, a harmonic reducer 1, a brake 3 and a driver 5, the servo motor 2 includes a stator 201 and a rotor 202, the stator 201 is connected to the housing 12, and the rotor 202 is connected to the input shaft 7, the input end of the harmonic reducer 1 is connected to the input shaft 7, the output end of the harmonic reducer 1 is connected to the output shaft 8, and the input shaft 7 is provided with a brake 3 at the end far away from the harmonic reducer 1 And the input end encoder 4, the output shaft 8 is provided with an output end encoder 6 at the end away from the harmonic reducer 1, and the driver 5 is arranged between the input end encoder 4 and the output end encoder 6.

[0026] Wherein, both the input end encoder 4 and the output end encoder 6 are independent magnetic encoders, including an encoder circuit board 401, a magnetic ring brac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com