Packaging container for scoopable contents

a technology for scoopable contents and packaging containers, which is applied in packaging, non-removal of lids/covers, auxiliary devices, etc., can solve the problems of reducing the size of the container access opening, increasing the risk of feature contact, and less use of attachments, etc., to achieve tighter and slimmer attachments, high frequency welding, and high control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

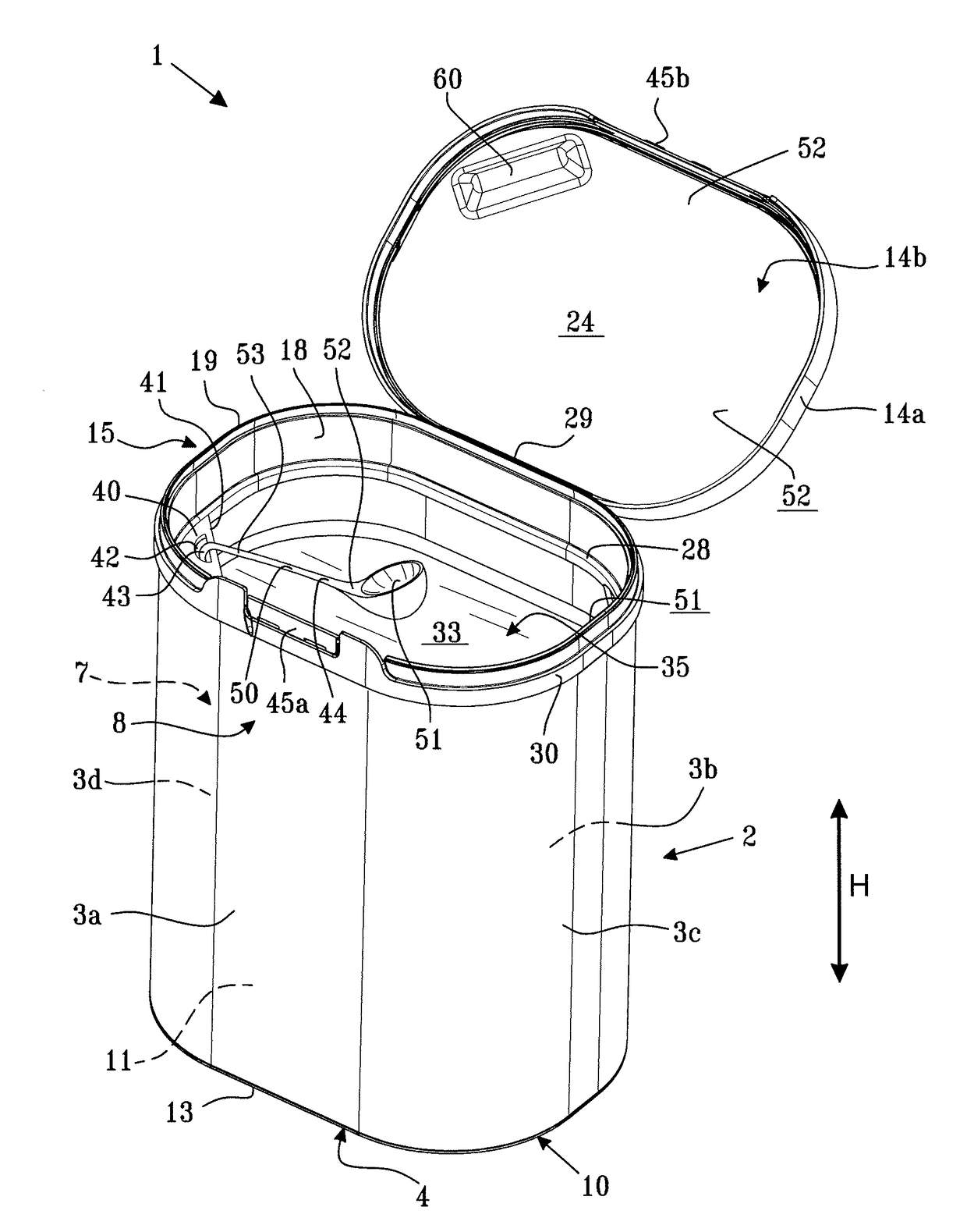

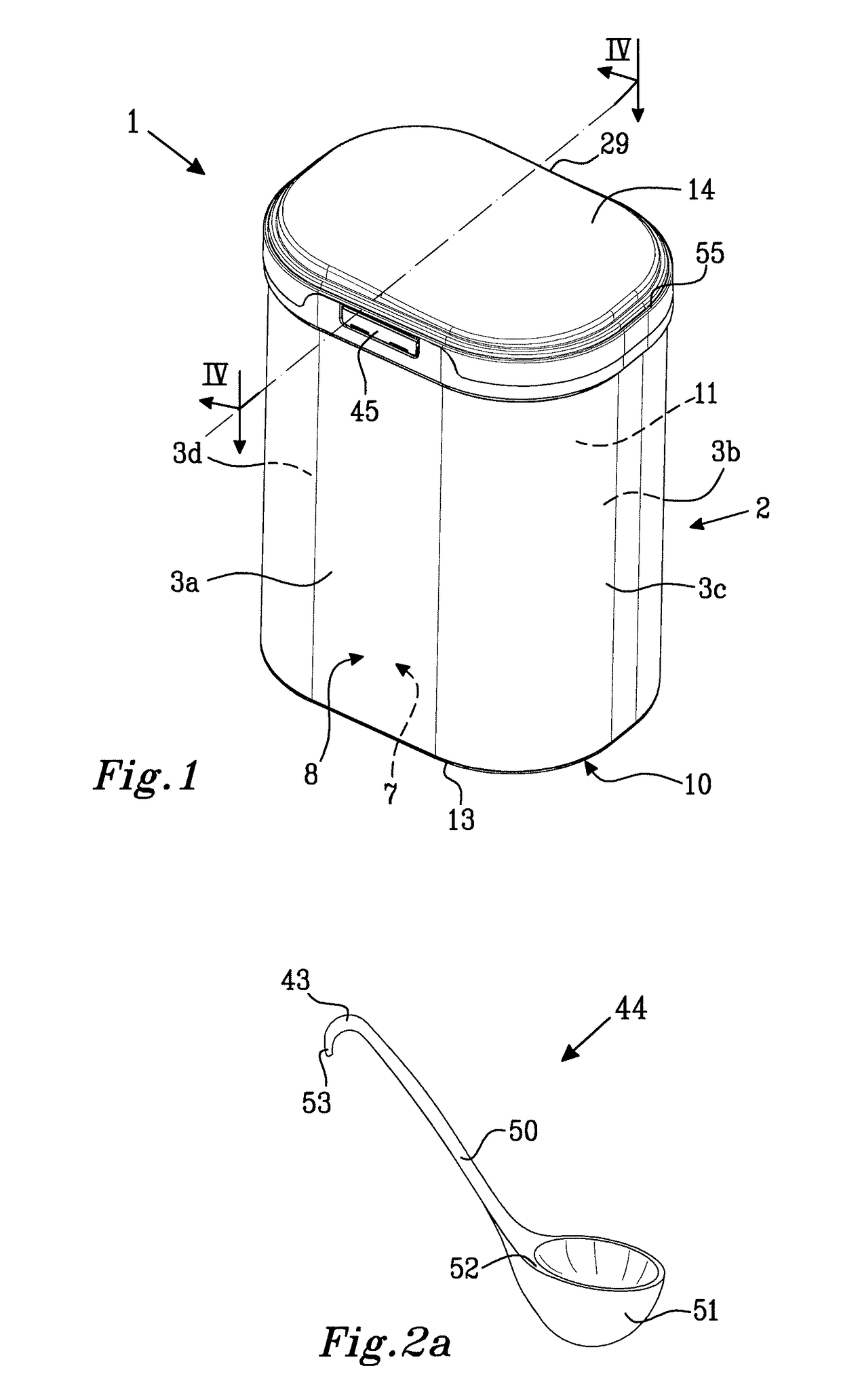

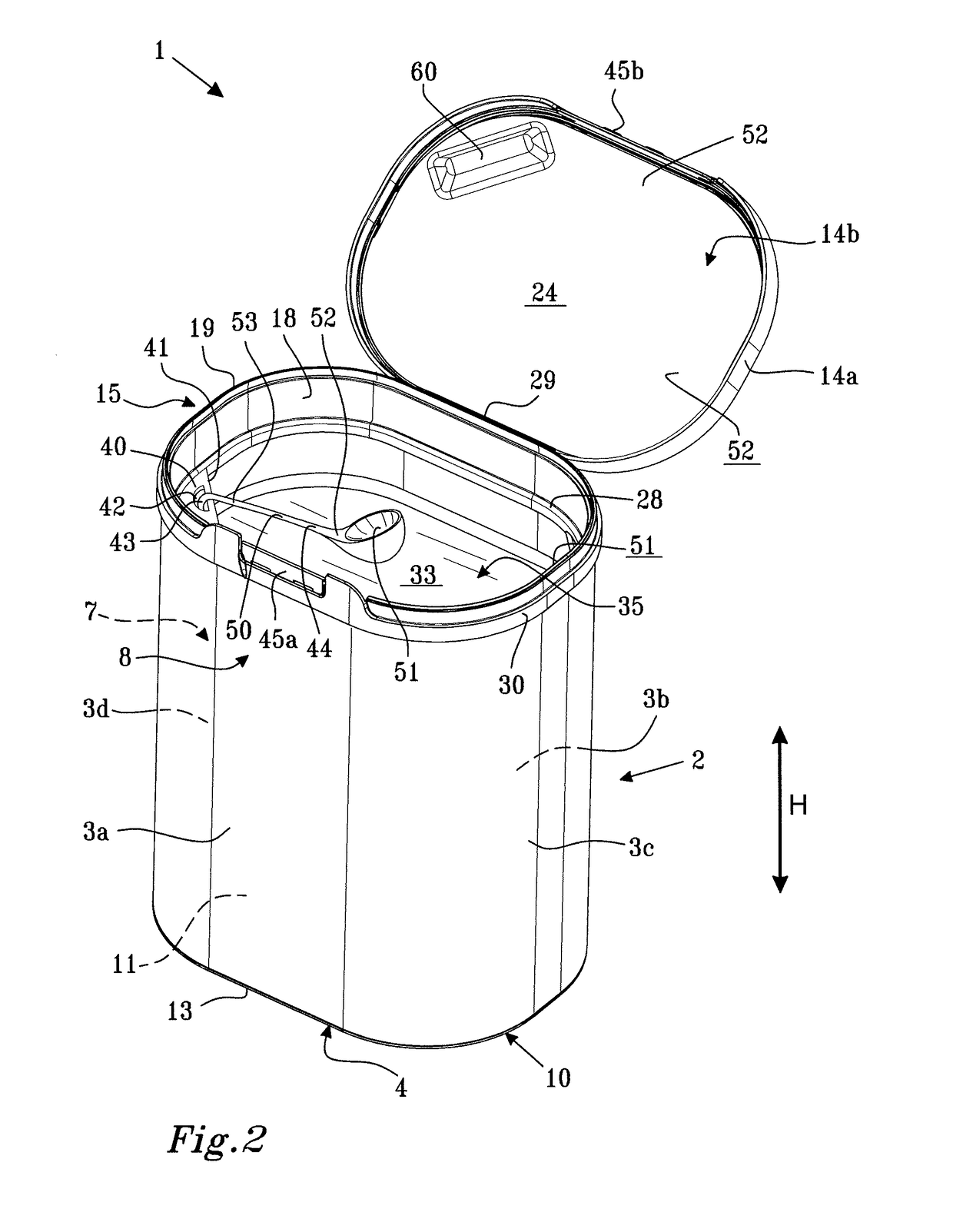

Embodiment Construction

[0063]It is to be understood that the drawings are schematic and that individual components, such as layers of material are not necessarily drawn to scale. The packaging container, reinforcing rim and lid component shown in the figures are provided as examples only and should not be considered limiting to the invention. The combined scraper bar and scoop holder as disclosed herein, may be used with packaging containers having completely removable lids. The combined scraper bar and scoop holder as disclosed herein is also useful in packaging containers having a hinge-lid arrangement different from the rim / frame arrangement shown in the figures. Such hinge-lid arrangement may be any suitable hinge-lid arrangement as known in the art including hinge-lid arrangements where the hinge is a two-part hinge and hinge-lid arrangement without a reinforcing rim and / or without a frame-structure. Accordingly, the scope of the invention is determined solely by the appended claims.

[0064]With refere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com