Preparation method for nano aluminum oxide reinforced highly wear-resistant liner plate

A nano-alumina and wear-resistant liner technology, which is applied in the field of metal material preparation, can solve the problems of inability to resist abrasive pressing and scratching, poor abrasive wear resistance, plastic deformation and low-cycle fatigue, and achieve wear resistance Increase, improve wear resistance, improve the effect of binding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

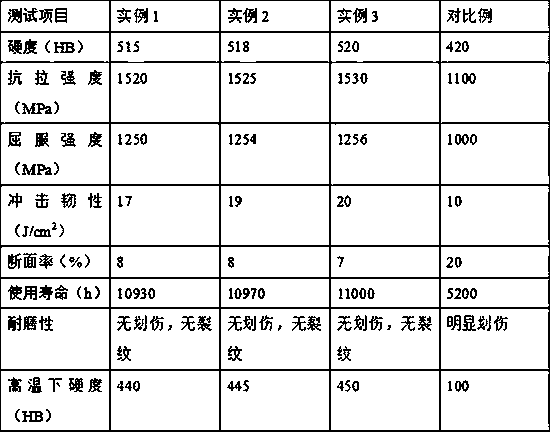

Examples

example 1

[0026]In parts by weight, mix 30 parts of barium oxide, 16 parts of boron oxide, 13 parts of aluminum oxide, 25 parts of cerium oxide and 3 parts of zirconia into a corundum crucible, move the corundum crucible into a muffle furnace, and heat up to 1450°C, heat preservation and sintering for 2 hours, take out the corundum crucible, and quench it with 20°C water for 20 minutes to obtain rare earth ceramic blocks; put the rare earth ceramic blocks into a mortar and grind for 3 hours, pass through a 400-mesh sieve to obtain ceramic powder, and take suitable steel plate castings , polished with 400-mesh sandpaper for 8 minutes, then scrubbed the surface of the steel plate with acetone, prepared a sodium hydroxide solution with a mass fraction of 20%, heated to 60°C to obtain lye, cleaned the steel plate with lye for 10 minutes, and then rinsed with deionized water The steel plate is obtained base plate 3 times; In parts by weight, 1 part of nickel powder, 10 parts of ferromanganese...

example 2

[0028] In parts by weight, mix 32 parts of barium oxide, 17 parts of boron oxide, 14 parts of aluminum oxide, 27 parts of cerium oxide and 4 parts of zirconia into a corundum crucible, move the corundum crucible into a muffle furnace, and heat up to 1470°C, heat preservation and sintering for 2.5 hours, take out the corundum crucible, and quench it with 22°C water for 22 minutes to obtain rare earth ceramic blocks; put the rare earth ceramic blocks into a mortar and grind for 3.5 hours, pass through a 400-mesh sieve to obtain ceramic powder, take a suitable Steel plate castings, polished with 400 mesh sandpaper for 9 minutes, then scrubbed the surface of the steel plate with acetone, prepared a sodium hydroxide solution with a mass fraction of 20%, heated to 65°C to obtain lye, cleaned the steel plate with lye for 12 minutes, and then deionized Rinse the steel plate with water for 3 times to obtain the base plate; in parts by weight, 1 part of nickel powder, 11 parts of ferroma...

example 3

[0030] In parts by weight, mix 35 parts of barium oxide, 18 parts of boron oxide, 15 parts of aluminum oxide, 30 parts of cerium oxide and 5 parts of zirconia into a corundum crucible, move the corundum crucible into a muffle furnace, and heat up to 1500°C, heat preservation and sintering for 3 hours, take out the corundum crucible, and quench it with 25°C water for 25 minutes to obtain rare earth ceramic blocks; put the rare earth ceramic blocks into a mortar and grind for 4 hours, pass through a 400-mesh sieve to obtain ceramic powder, and take suitable steel plate castings , polished with 400-mesh sandpaper for 10 minutes, then scrubbed the surface of the steel plate with acetone, prepared a sodium hydroxide solution with a mass fraction of 20%, heated to 70°C to obtain lye, cleaned the steel plate with lye for 15 minutes, and rinsed with deionized water The steel plate is obtained base plate 4 times; In parts by weight, 2 parts of nickel powder, 12 parts of ferromanganese, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com