Preparation method of O3/H2O2 catalyst using activated bentonite as carrier, catalyst and application thereof

A technology for activating bentonite and catalysts, applied in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc. Difficulty and other problems, to achieve large-scale industrial production, prevent secondary pollution, and reduce operating costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

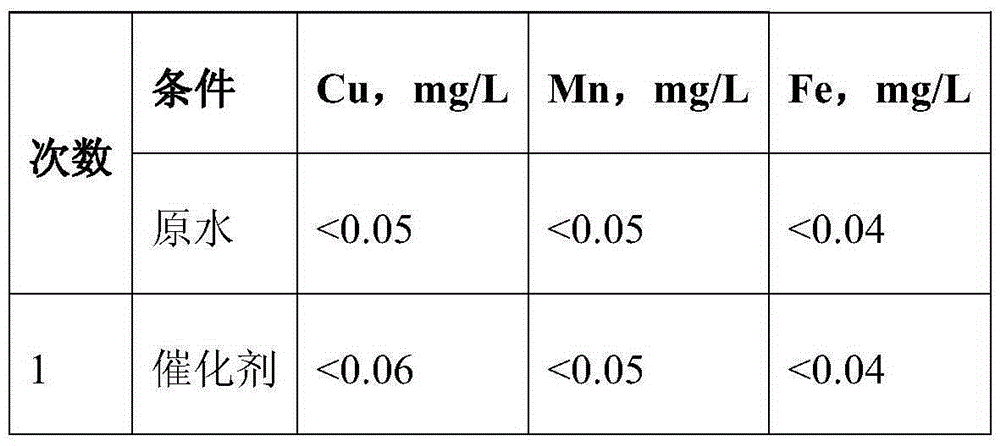

Embodiment 1

[0027] Add 5mol / L nitric acid solution into bentonite, and control the mass ratio of nitric acid solution to bentonite at 1:200; stir and react at 80°C for 6h, then let stand for 4h, then filter, wash until neutral, and dry at 150°C for 2h , roasted at 800°C for 5 hours, ground and sieved 200 meshes to obtain activated bentonite; take part of activated bentonite, and prepare spherical raw material cores with a particle size of 2.5mm through a sugar coating preparation machine; take another part of activated bentonite, add quantitative Mn(NO 3 ) 2 , Fe(NO 3 ) 3 、Al 2 (SO 4 ) 3 , Cu(NO 3 ) 2 Mix evenly in the metal ion solution, the mass ratio of the four salts is 2:5:2:1, the mass fraction of the metal ion solution is 30%, and the mass ratio of the activated bentonite to the metal ion solution is 20:1. Stir at 80°C for 6 hours and let it stand for 10 hours to obtain the activated bentonite loaded with metal ions; after mixing the spherical raw material core with the acti...

Embodiment 2

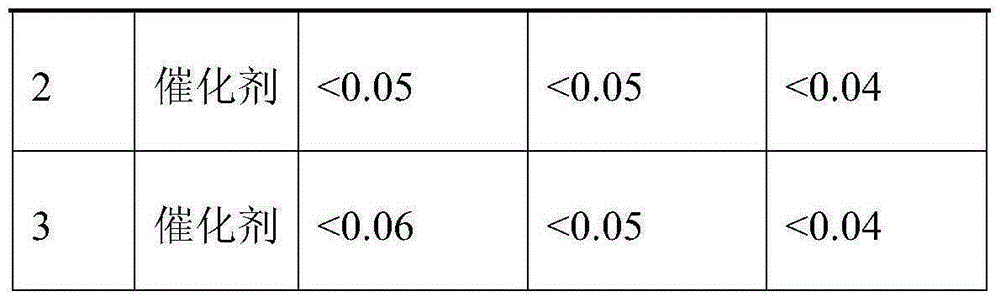

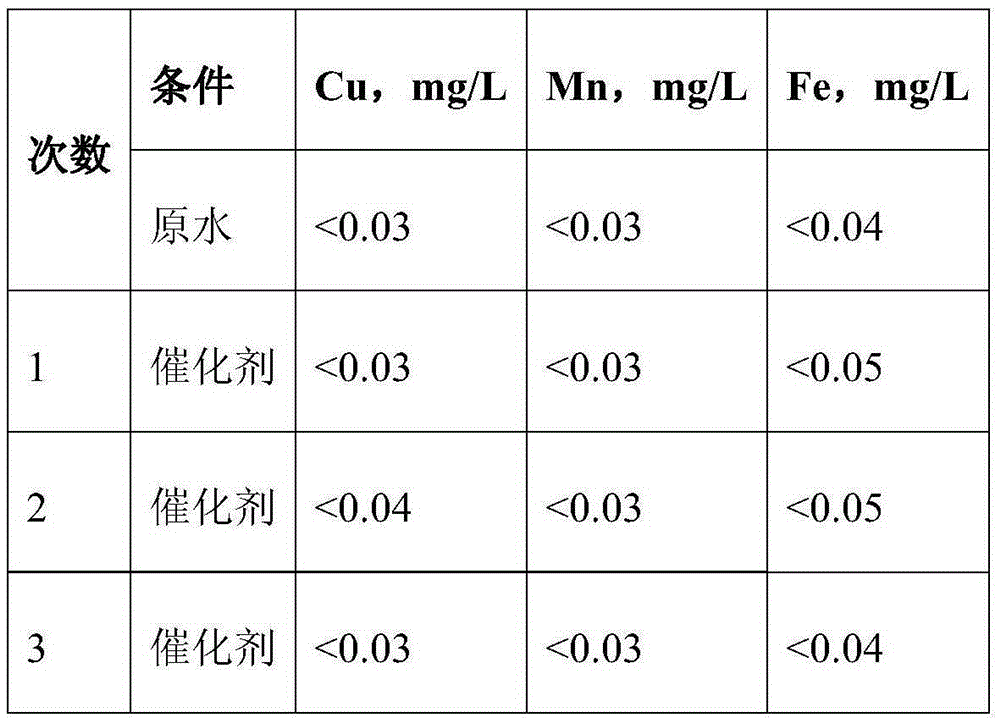

[0035] Add 10mol / L sulfuric acid solution into bentonite, and control the mass ratio of sulfuric acid solution to bentonite at 1:500; stir and react at 50°C for 8h, then let stand for 5h, then filter, wash until neutral, and dry at 160°C for 1h , roasted at 1000°C for 4 hours, ground and sieved 250 meshes to obtain activated bentonite; take part of activated bentonite, and prepare spherical raw material cores with a particle size of 1mm through a sugar coating preparation machine; take another part of activated bentonite, add quantitative MnSO 4 , Fe 2 (SO 4 ) 3 、Al 2 (SO 4 ) 3 、CuSO 4 Mix evenly in the metal ion solution, the mass ratio of the four salts is 2:5:2:1, the mass fraction of the metal ion solution is 5%, and the mass ratio of the activated bentonite to the metal ion solution is 10:1. Stir at 50°C for 8 hours and let stand for 12 hours to obtain the activated bentonite loaded with metal ions; after mixing the spherical raw material core with the activated ben...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com