Reactor preventing accumulation of solid material

A technology for solid materials and reaction kettles, applied in the field of reaction kettles to avoid accumulation of solid materials, can solve problems such as increased energy consumption, long time, side reactions, etc., and achieve the effects of eliminating potential safety hazards, promoting interface reactions, and facilitating replacement.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

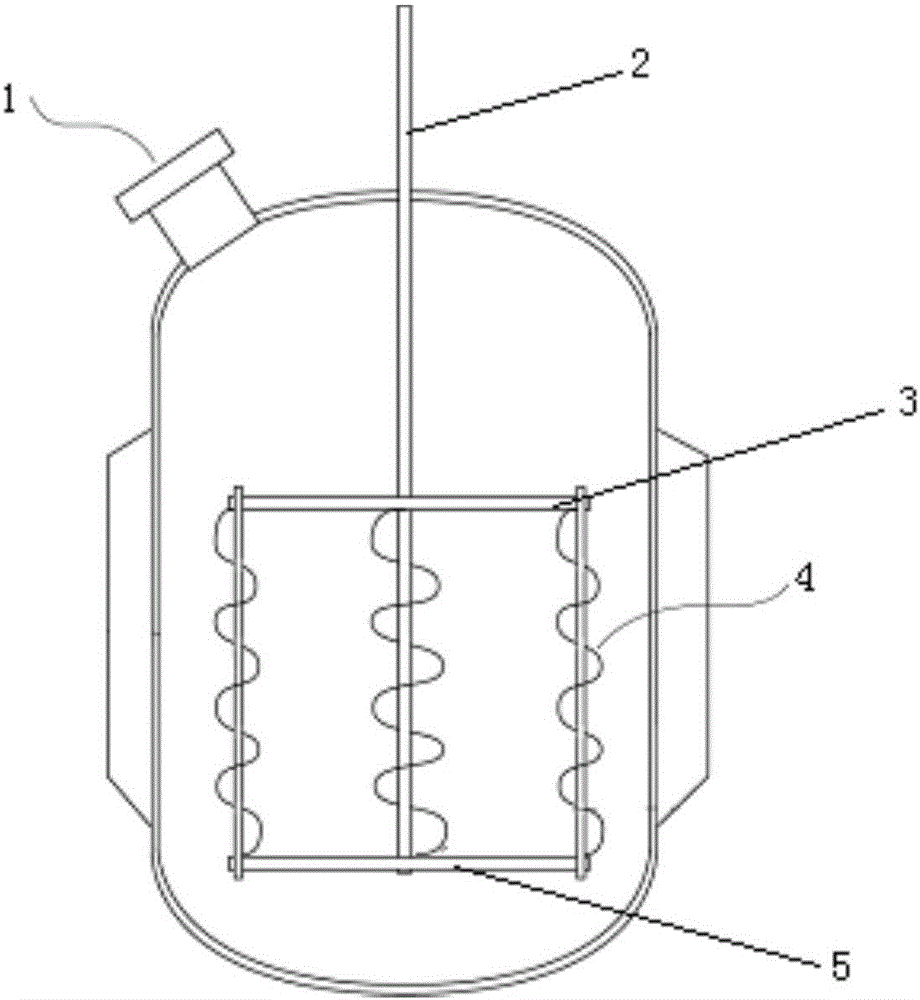

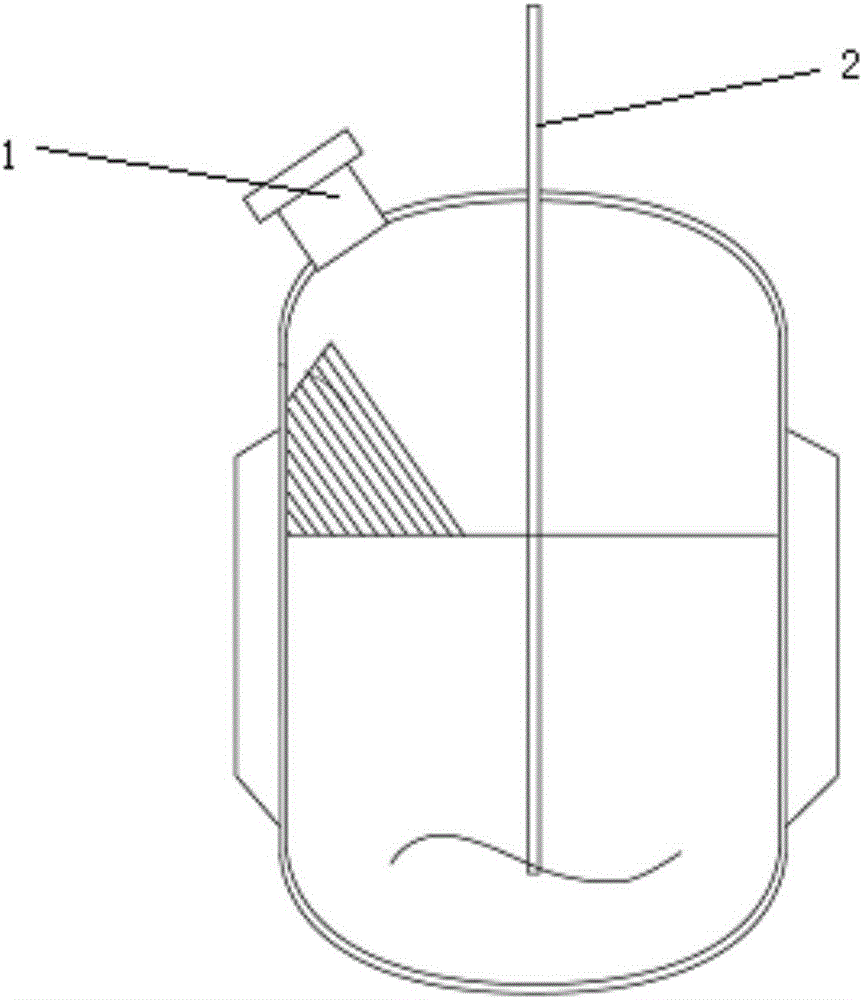

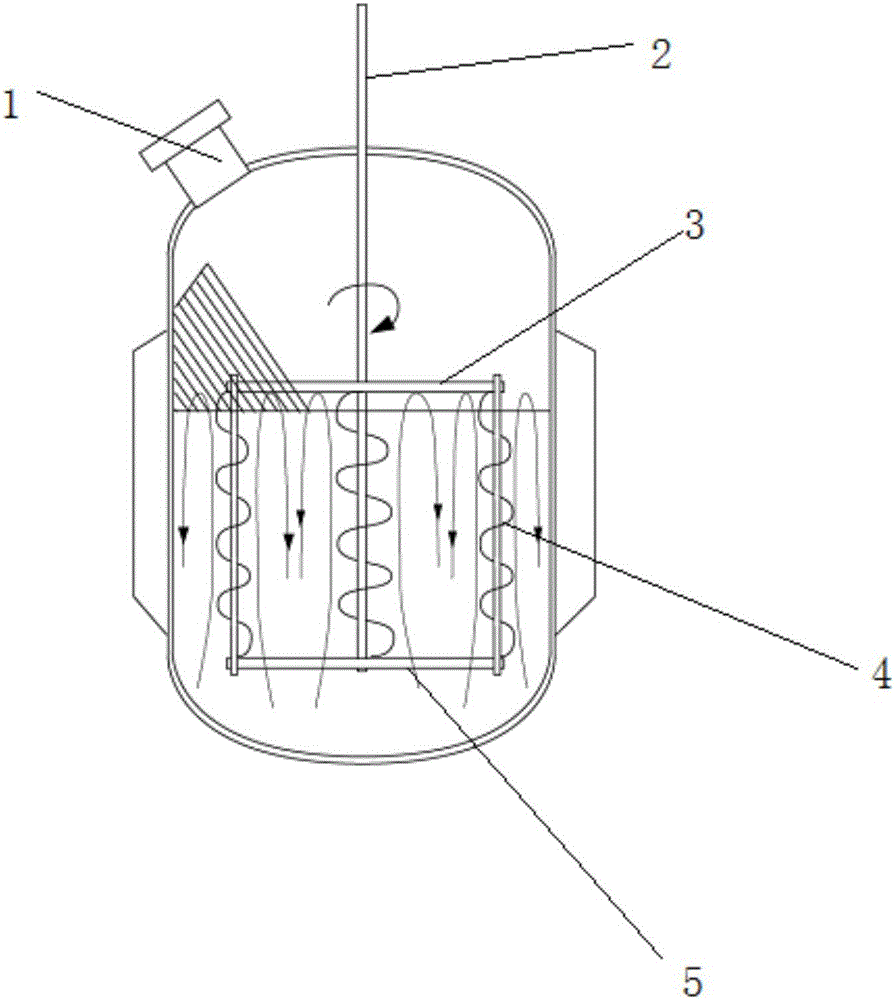

[0018] Example: such as figure 1 Shown is the structural diagram of this embodiment, including: a kettle body and an agitator, and the top of the kettle body is provided with a feed inlet 1; The middle and lower part of the rod 2 is provided with a fixed frame 3, and a plurality of detachable belt-type spiral stirring blades 4 are evenly arranged on the fixed frame 3, and the length direction of the belt-type spiral stirring blades 4 is parallel to the length direction of the stirring rod 2.

[0019] Wherein the fixed frame 3 is a ring-shaped plate, the inner wall of the central circular hole of the ring-shaped plate is provided with an internal thread, and the outer wall of the middle and lower part of the stirring rod 2 is provided with an external thread matched with the internal thread, and the ring-shaped plate and the stirring rod 2 Screwed through the thread structure; the plate surface of the circular plate is parallel to the cross section of the kettle body. Through-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com