Leaching equipment

A kind of equipment and leaching technology, which is applied in the direction of liquid solution solvent extraction, etc., can solve the problems of short service life, inability to meet the requirements of acid pulp leaching, low leaching efficiency, etc., and achieve the effect of long service life, high leaching efficiency and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

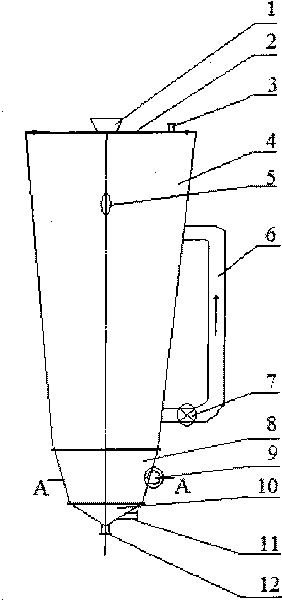

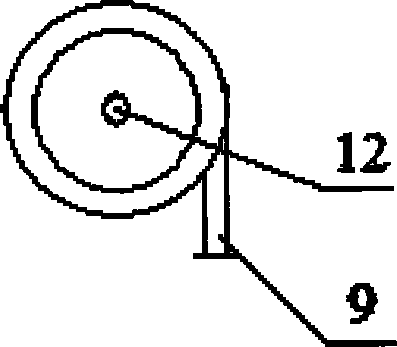

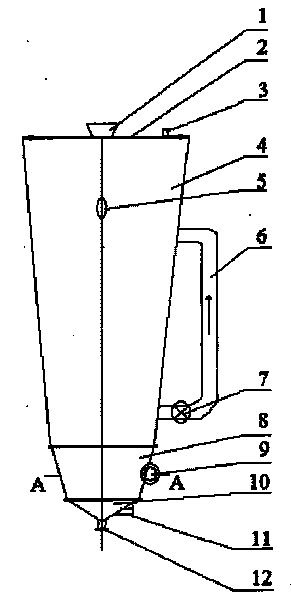

[0020] A kind of leaching equipment such as figure 1 Shown: Including the upper cone 4, the lower cone 8 and the bottom cone 10. The upper end of the upper cone 4 is fixedly connected with a cover plate 2, and the center of the cover plate 2 is provided with a feed port 1, and the cover plate 2 is provided with an exhaust hole 3 near the periphery; Observation hole 5, the shell of the upper cone 4 is equipped with a circulation pipe 6, the circulation pipe 6 communicates with the inner cavity of the upper cone 4, the pipe of the circulation pipe 6 is connected with a water pump 7; the lower port of the upper cone 4 and the lower cone The upper port of the body 8 is fixedly connected, the lower port of the lower cone 8 is fixedly connected with the upper port of the bottom cone 10, the shell of the lower cone 8 is provided with a steam inlet 9 which is located at a height of 0.48 of the lower cone 8, A flushing water inlet 11 is provided at the cone height of the bottom cone 10 ...

Embodiment 2

[0028] A leaching equipment, except for the following parameters, the rest are the same as in Example 1:

[0029] The steam inlet 9 is located at the height of the lower cone 8 at 0.52, the bottom cone (10) is provided with a flushing water inlet (11) at the cone height of 0.52; the ratio of the diameter of the upper port of the upper cone 4 to the lower port of the upper cone 4 1.8:1, the ratio of the height of the upper cone 4 to the diameter of the upper port of the upper cone 4 is 3.5:1; the lower end of the circulation pipe 6 is installed at a distance of 1 / 6 of the height of the upper cone 4 from the lower end of the upper cone 4 The upper end of the circulation pipe 6 is installed at 3 / 4 of the height of the upper cone 4 from the lower end of the upper cone 4; the ratio of the upper port diameter of the lower cone 8 to the lower port diameter of the lower cone 8 is 1.4:1 , The ratio of the height of the lower cone 8 to the diameter of the upper port of the lower cone 8 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com