Inhibitor-loaded montmorillonite/epoxy self-healing coating

A technology of montmorillonite and corrosion inhibitor, which is applied in the field of montmorillonite/epoxy self-healing coatings to achieve the effects of simple process, improved corrosion resistance and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

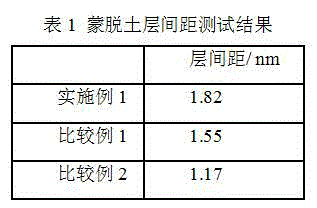

Embodiment 1

[0031] (1.1) Mix montmorillonite and deionized water at a ratio of 1:80, and stir magnetically for 24 hours to obtain a montmorillonite solution; another mixture of octadecylamine and deionized water at a ratio of 1:25 adjusts the pH of the solution value to 3~4, after stirring for 30 minutes, slowly add it into the vigorously stirred montmorillonite solution, react at 80°C for 24 hours, and centrifugally filter;

[0032] (1.2) Mix montmorillonite with a mixed solvent (water: acetone = 1:1) at a ratio of 1:10, disperse at high speed and ultrasonically, then mix the corrosion inhibitor and modified montmorillonite at a mass ratio of 1:10 , evacuated for 5 hours, centrifuged and washed several times to obtain montmorillonite loaded with corrosion inhibitor.

Embodiment 2

[0041] (1) Add the loaded corrosion inhibitor montmorillonite obtained in Example 1 to the epoxy resin at a mass ratio of 3%, add additives and solvents at a mass ratio of 3.5% and 35.07%, and ball mill for 4 hours to obtain a loaded corrosion inhibitor Agent montmorillonite / epoxy coating component one.

[0042] (2) Mix the curing agent and the solvent at a ratio of 1:1, disperse at high speed for 15 minutes, and prepare the second component of the loaded corrosion inhibitor montmorillonite / epoxy coating. Component 1 and Component 2 were mixed in proportion, and then sprayed on the steel plate by spraying method, and dried for 7 days to obtain montmorillonite / epoxy coating loaded with corrosion inhibitor.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com