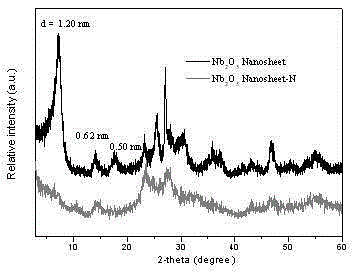

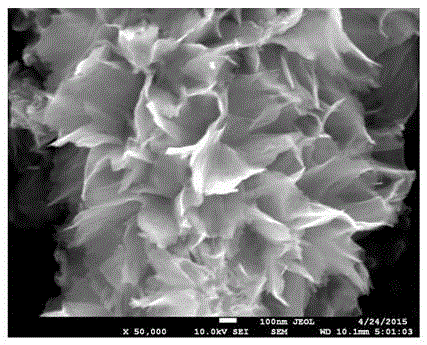

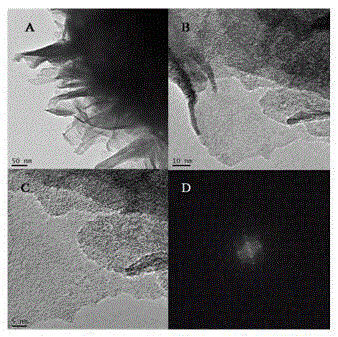

Preparation method of carbon and nitrogen doped niobium (V) pentoxide nano sheet and application of nano sheet as photocatalyst

A technology of niobium pentoxide and nanosheets, applied in the fields of nanomaterials and catalysis, can solve the problems of many steps and low synthesis efficiency, and achieve the effects of low reaction temperature, low cost and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing niobium pentoxide nanosheets doped with carbon and nitrogen, comprising the steps of:

[0024] At room temperature (10-40°C), 3.24g of niobium pentachloride was dissolved in 40ml of absolute ethanol, ultrasonicated for 10 minutes to form a clear and transparent solution, and then 25ml of 25% tetramethanone was added dropwise to the ethanol solution Base ammonium hydroxide solution, control the rate of addition of 0.27ml / min, stirred for 30 minutes to obtain a clear solution. Transfer the solution to a 100ml reaction kettle with a polytetrafluoroethylene liner, conduct a hydrothermal reaction at 240°C for 24 hours, cool to room temperature, filter with filter paper, wash with 2000-3000ml of distilled water, and then wash with absolute ethanol washing. The filtrate was dried at 100° C. for 8 hours to obtain niobium pentoxide nanosheets. The obtained niobium pentoxide nanosheets were calcined in a nitrogen atmosphere at 500° C. in a muffle furnace ...

Embodiment 2

[0031] A method for preparing niobium pentoxide nanosheets doped with carbon and nitrogen, comprising the steps of:

[0032] At room temperature (10-40°C), 3.24g of niobium pentachloride was dissolved in 40ml of absolute ethanol, ultrasonicated for 10 minutes to form a clear and transparent solution, and then 30ml of 25% tetraethyl ethyl chloride was added dropwise to the ethanol solution Base ammonium hydroxide solution, control the rate of addition of 0.27ml / min, stirred for 30 minutes to obtain a clear solution. Transfer the solution to a 100ml reaction kettle with a polytetrafluoroethylene liner, and conduct a hydrothermal reaction at 220°C for 24 hours. After cooling to room temperature, filter with filter paper, wash with 2000-3000ml of distilled water, and then wash with absolute ethanol washing. The filtrate was dried at 100° C. for 8 hours to obtain niobium pentoxide nanosheets. The obtained niobium pentoxide nanosheets were calcined in a nitrogen atmosphere at 400°...

Embodiment 3

[0034] A method for preparing niobium pentoxide nanosheets doped with carbon and nitrogen, comprising the steps of:

[0035] At room temperature (10-40°C), 1.5g of ammonium niobium oxalate was dissolved in 30ml of absolute ethanol, ultrasonicated for 10 minutes to form a clear and transparent solution, and then 35ml of 25% tetramethyl Ammonium hydroxide solution was controlled at a rate of 0.27ml / min, and stirred for 30 minutes to obtain a clear solution. Transfer the solution to a 100ml reaction kettle with a polytetrafluoroethylene liner, conduct a hydrothermal reaction at 250°C for 24 hours, cool to room temperature, filter with filter paper, wash with 2000-3000ml of distilled water, and then wash with absolute ethanol washing. The filtrate was dried at 100° C. for 8 hours to obtain niobium pentoxide nanosheets. The obtained niobium pentoxide nanosheets were calcined in a nitrogen atmosphere at 600° C. in a muffle furnace for 2 hours to obtain carbon and nitrogen doped ni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com