Flue baffle for gas-fired hot water tanks

a technology for hot water tanks and flue pipes, which is applied in the direction of steam generation, furnace-tube steam boilers, steam boilers, etc., can solve the problems of reducing affecting the efficiency of hot water heaters, etc., and achieves low labor costs and low fabrication costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

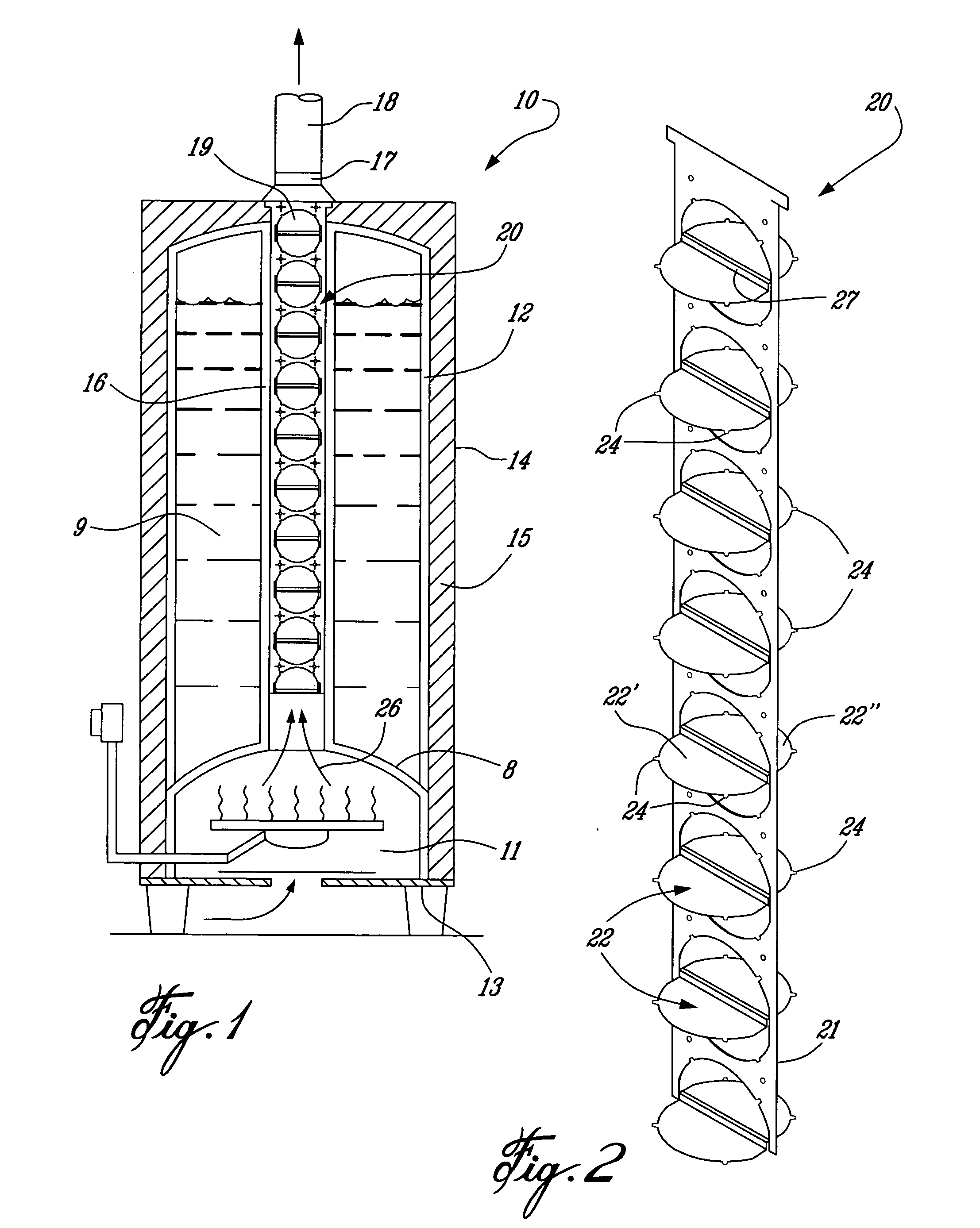

[0016]Referring now to the drawings and more particularly to FIG. 1, there is shown generally at 10 a hot water heater of the type provided with a gas or oil burner chamber 11 at a lower end of an inner tank housing 12. The inner tank housing 12 is supported on a base 13 and concealed within an outer thin metal casing 14. Insulating material 15 is disposed between the inner casing 12 and the outer casing 14.

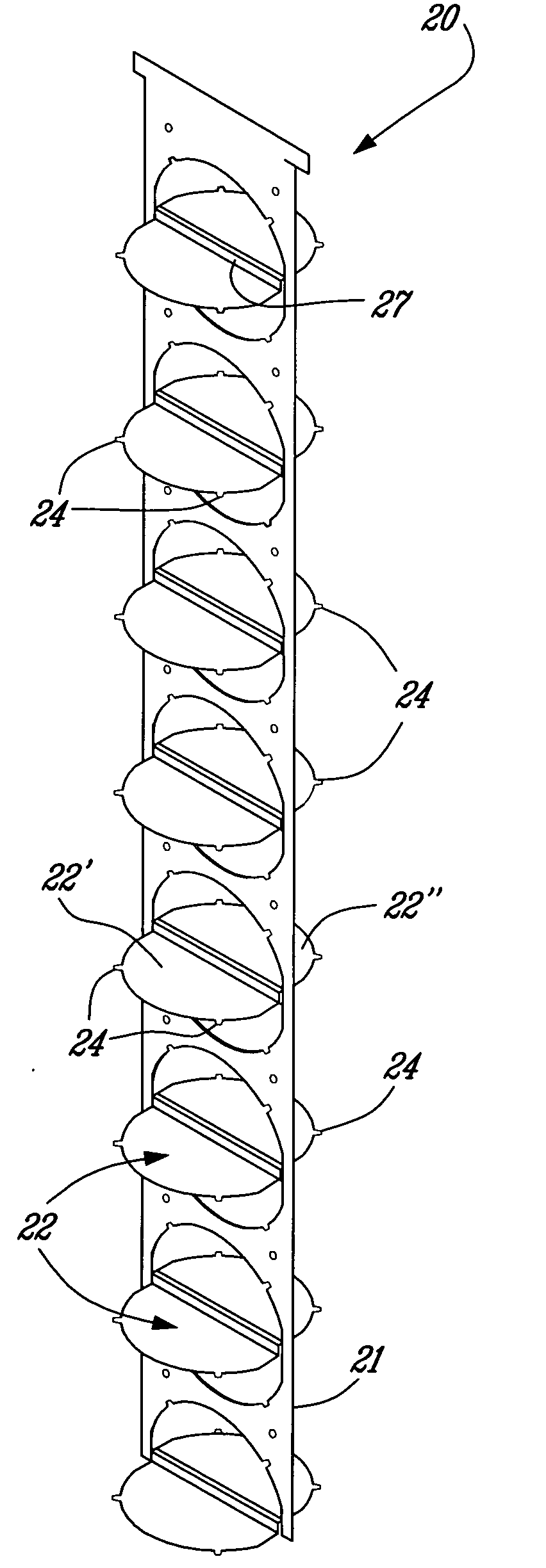

[0017]As hereinshown a flue pipe 16 extends centrally within the inner tank housing 12 and exits the hot water heater through a coupling 17 at a top end to couple the flue pipe 16 to an exhaust duct 18. Although not shown, a fan is usually connected to the exhaust duct to draw the combustion gases through the flue pipe 16 to exhaust the combustion gases to atmosphere. As hereinshown, the flue baffle 20 of the present invention is suspended into the flue pipe 16.

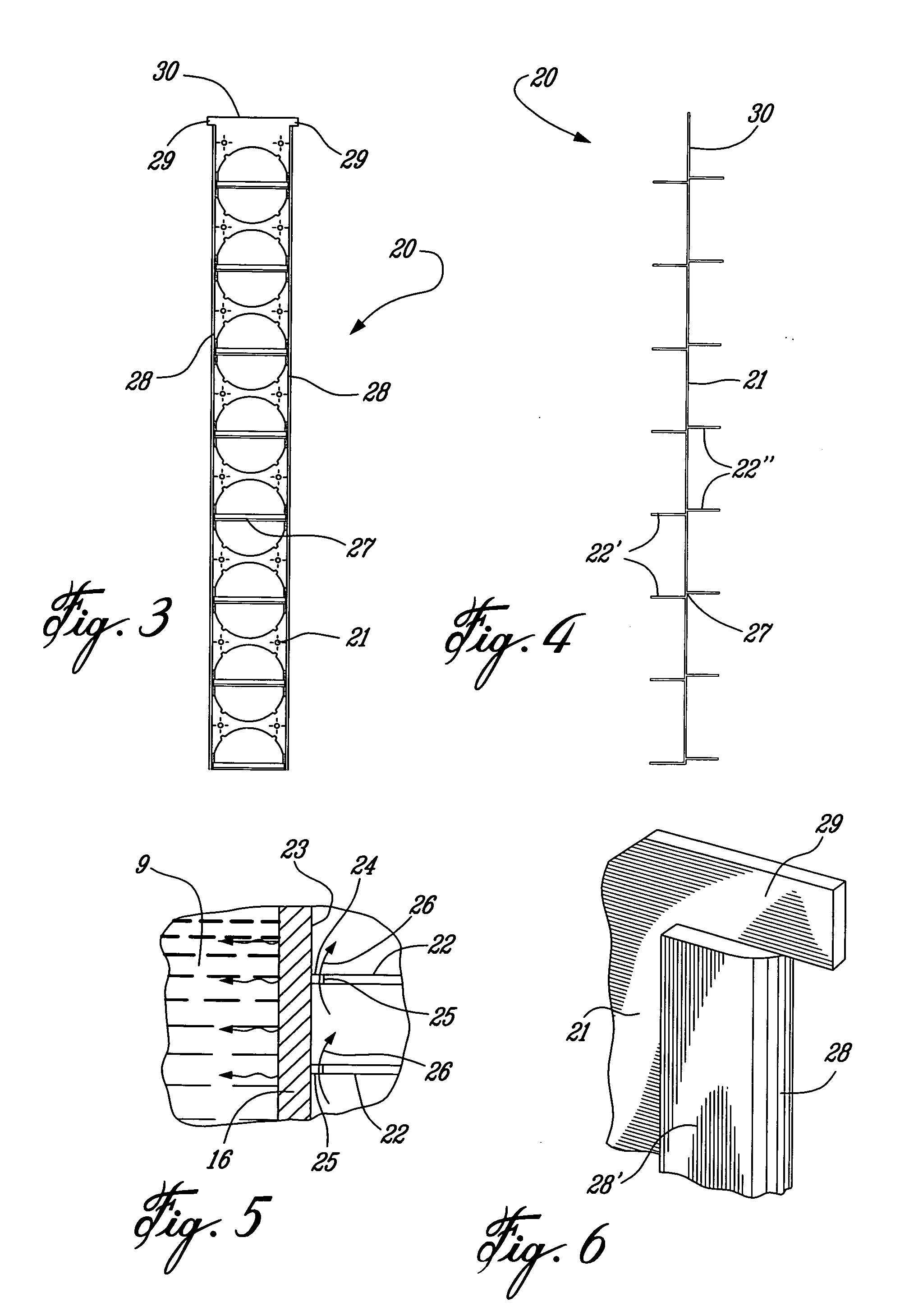

[0018]Referring now to FIGS. 2 to 6, there will be described the construction and operation of the flue baffle 20 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com