Scroll compressor

A scroll compressor and scroll technology, applied in the direction of rotary piston machines, rotary piston pumps, mechanical equipment, etc., can solve the problems of increased discharge loss and cost increase, and achieve reduced discharge loss, less oil discharge, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

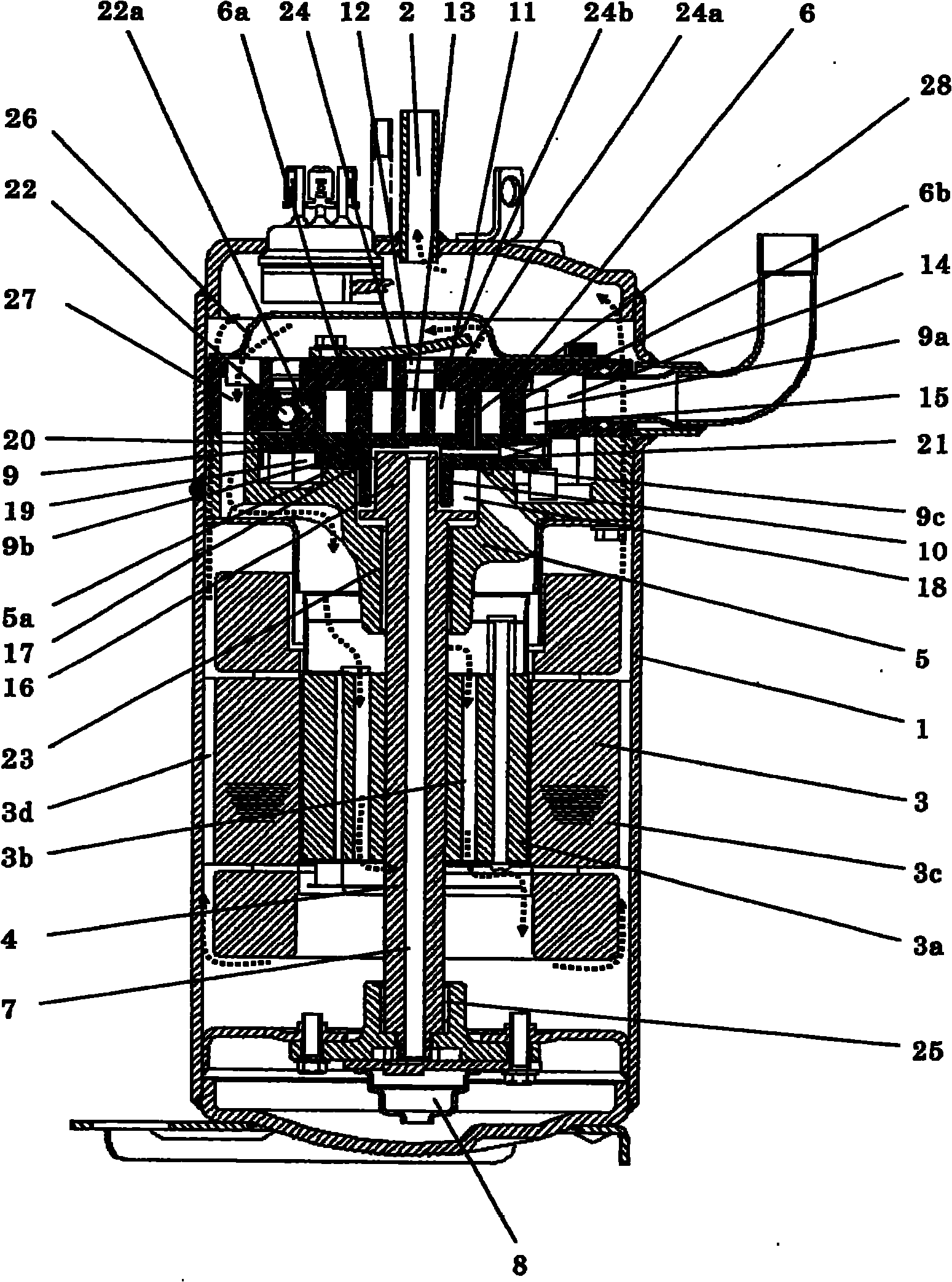

[0050] figure 1 It is a longitudinal sectional view of the scroll compressor according to Embodiment 1 of the present invention. exist figure 1 Among them, the entire interior of the iron airtight container 1 is a high-pressure environment communicated with the discharge pipe 2, an electric motor 3 is arranged in its central part, and a compression mechanism is arranged on the upper part, and the main body frame 5 of the compression mechanism is fixed on the airtight container 1 One end of the crankshaft 4 of the rotor 3a of the motor 3 is supported on the body frame 5, and a fixed scroll 6 is installed on the body frame 5.

[0051] An axial oil passage 7 is provided on the crankshaft 4 , one end of which leads to the oil supply pump device 8 , and the other end eventually leads to the eccentric bearing 10 of the movable scroll 9 . The movable scroll 9, which meshes with the fixed scroll 6 and constitutes the compression chamber 11, is composed of a rotating mirror plate 9...

Embodiment 2

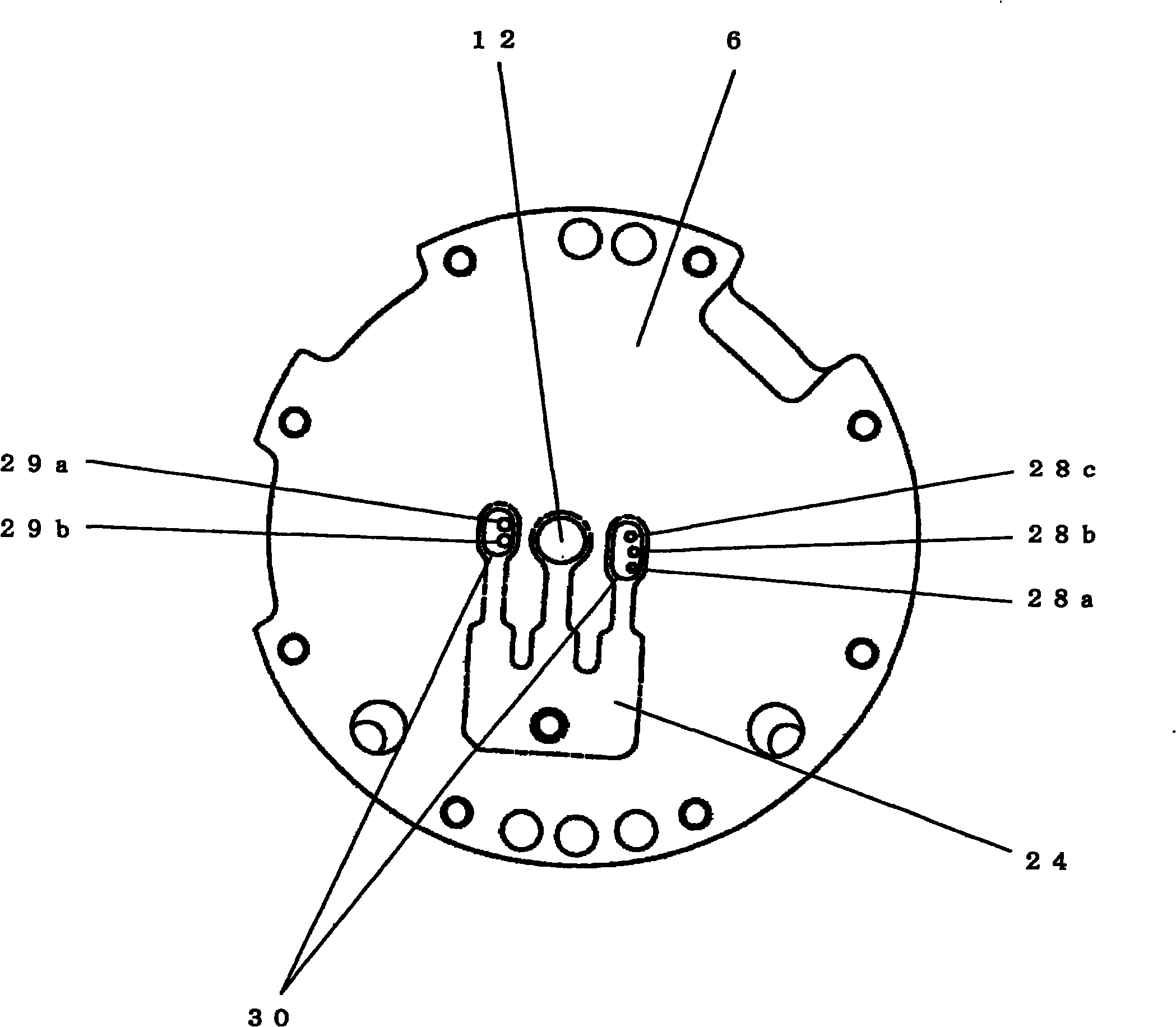

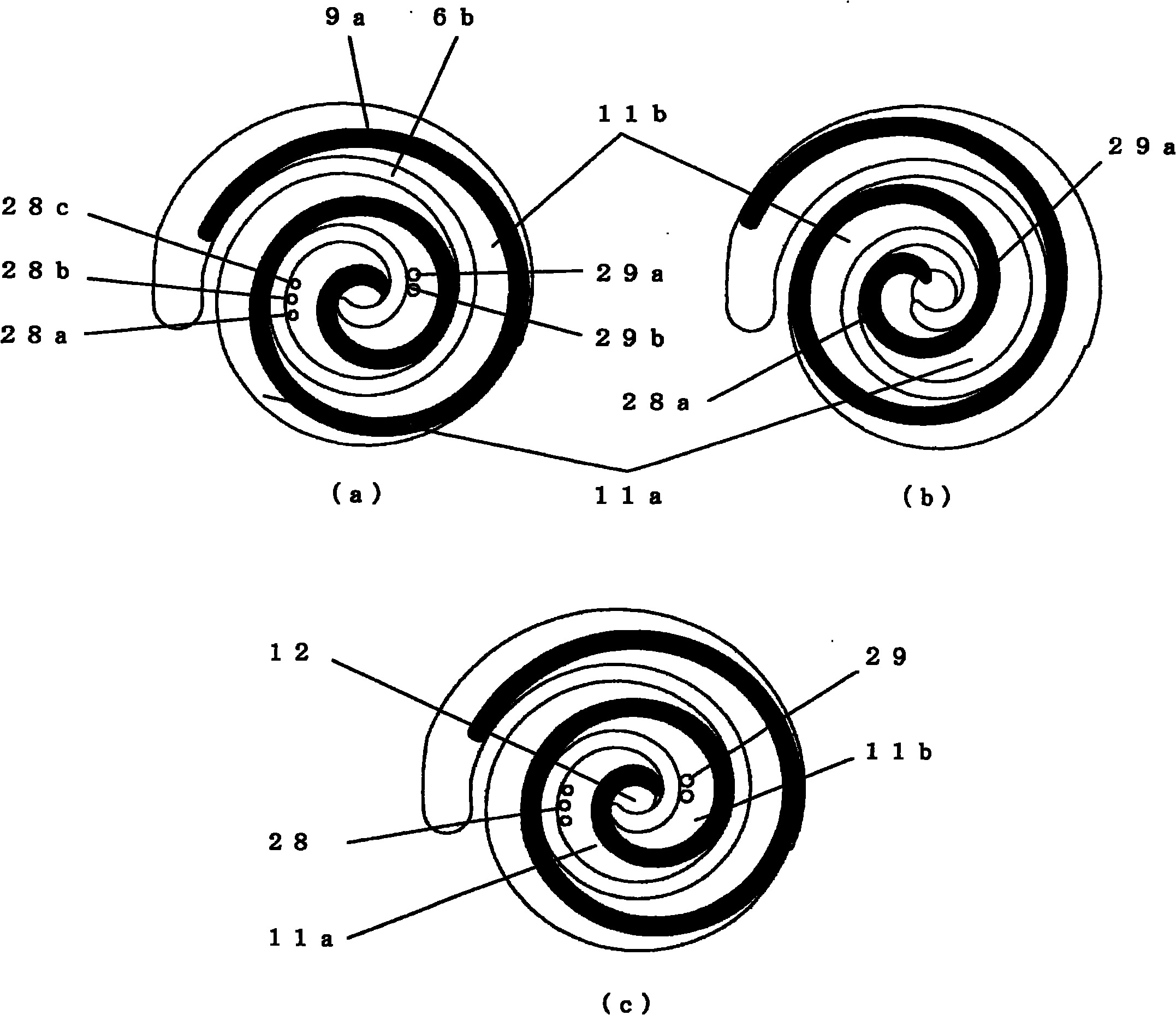

[0075] Figure 6 It is a transverse cross-sectional view of the compression mechanism part in Embodiment 2 of the present invention. The fixed scroll 6 is provided with a first bypass passage 28 composed of three holes 28a, 28b, 28c and a second bypass passage 29 composed of two holes 29a, 29b. Since the second bypass passage 29 Compared with the first bypass path 28, the number of holes is less and the area of the holes is larger. Therefore, as in Embodiment 1, the check valves of each bypass path 28, 29 and the discharge hole 12 can be arranged neatly and miniaturization.

[0076] At the same time, the center-to-center distance of the holes of the second bypass path 29 is set larger than that of the first bypass path 28 to ensure that the second bypass path 29 is opened in the second compression chamber 11b for as long as possible. , it can correspond to the compression ratio under a wide range of operating conditions, and reduce the discharge loss caused by excessive co...

Embodiment 3

[0080] Figure 7 It is a transverse sectional view of the compression mechanism part in Embodiment 3 of the present invention. The fixed scroll 6 is provided with a first bypass passage 28 composed of two holes 28a, 28b and a second bypass passage 29 composed of a hole 29a having a larger area than these holes 28a, 28b. 1 The closed volume of the compression chamber 11a is larger than that of the second compression chamber 11b, which is an asymmetric scroll structure. The total cross-sectional area of the first bypass path 28 is set to be larger than the total cross-sectional area of the second bypass path 29. bigger. Therefore, similar to Embodiment 1, the respective bypass passages 28, 29 and the check valves of the discharge hole 12 can be neatly arranged and miniaturized, and appropriate bypass valves can be set according to the closed volumes of the respective compression chambers 11a, 11b. The flow path cross-sectional area of the paths 28, 29 is reduced, thereby...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com