Scroll compressor

A scroll compressor and scroll technology, applied to rotary piston machinery, rotary piston pumps, mechanical equipment, etc., can solve problems such as performance degradation and increased lubricating oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

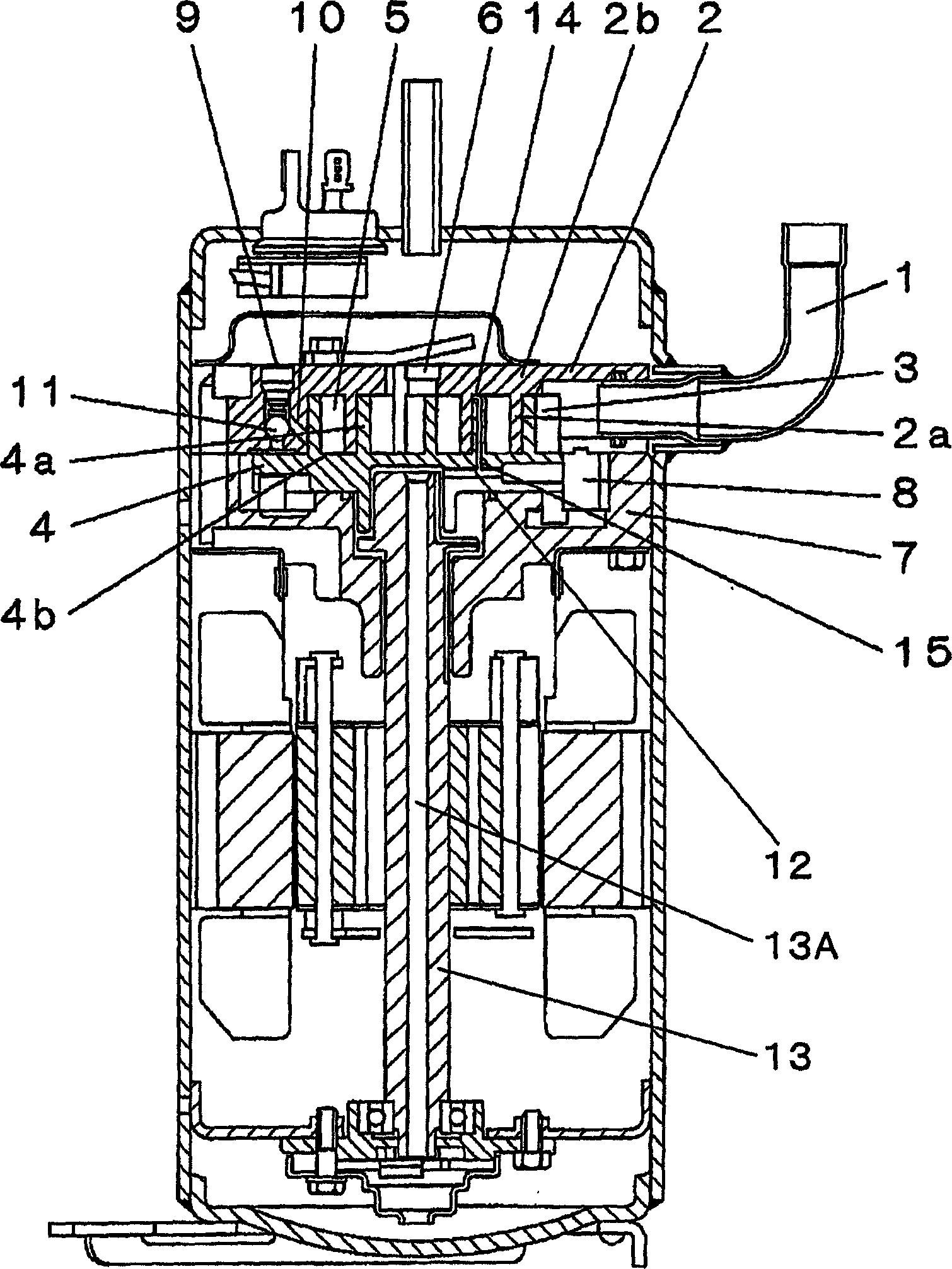

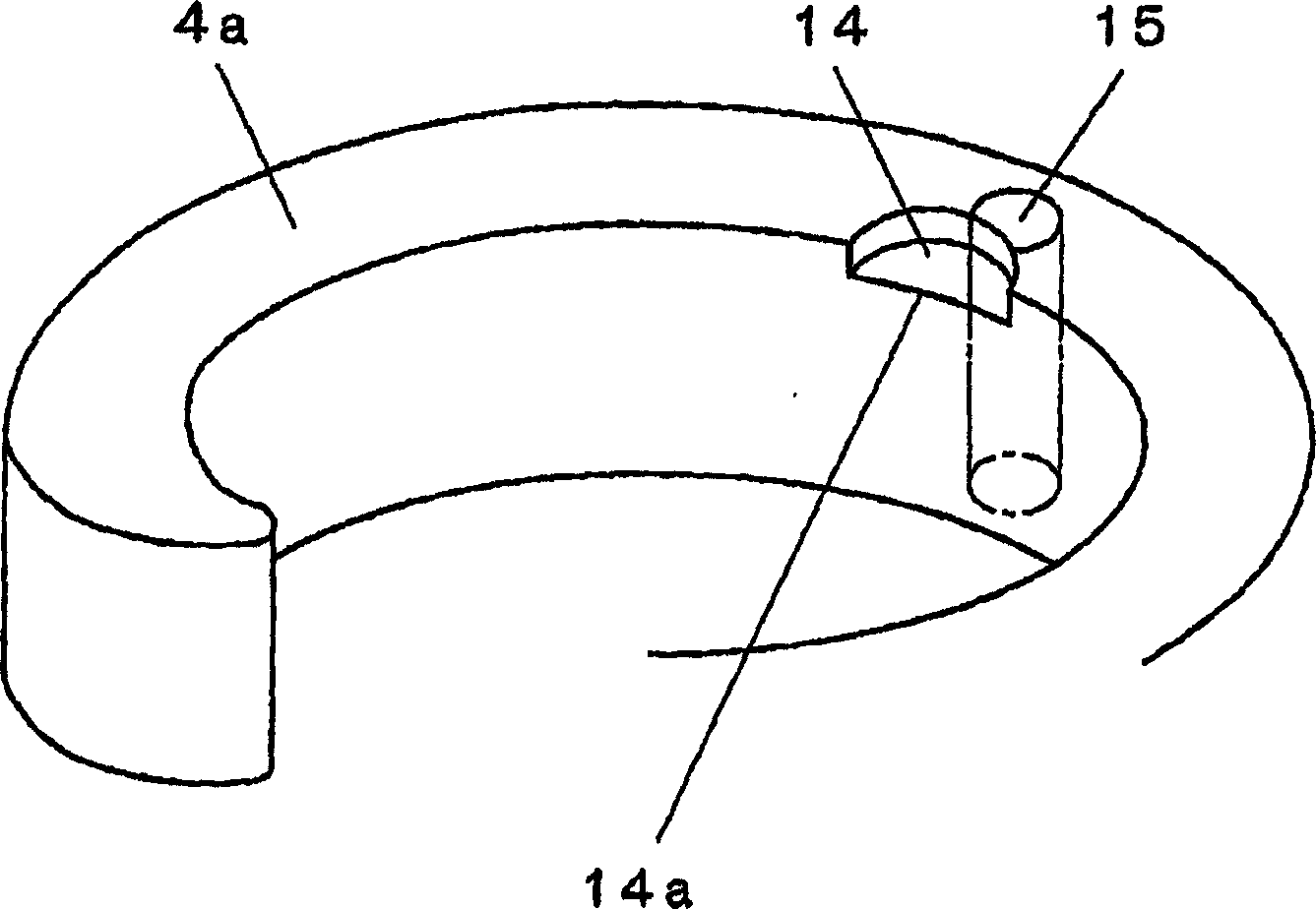

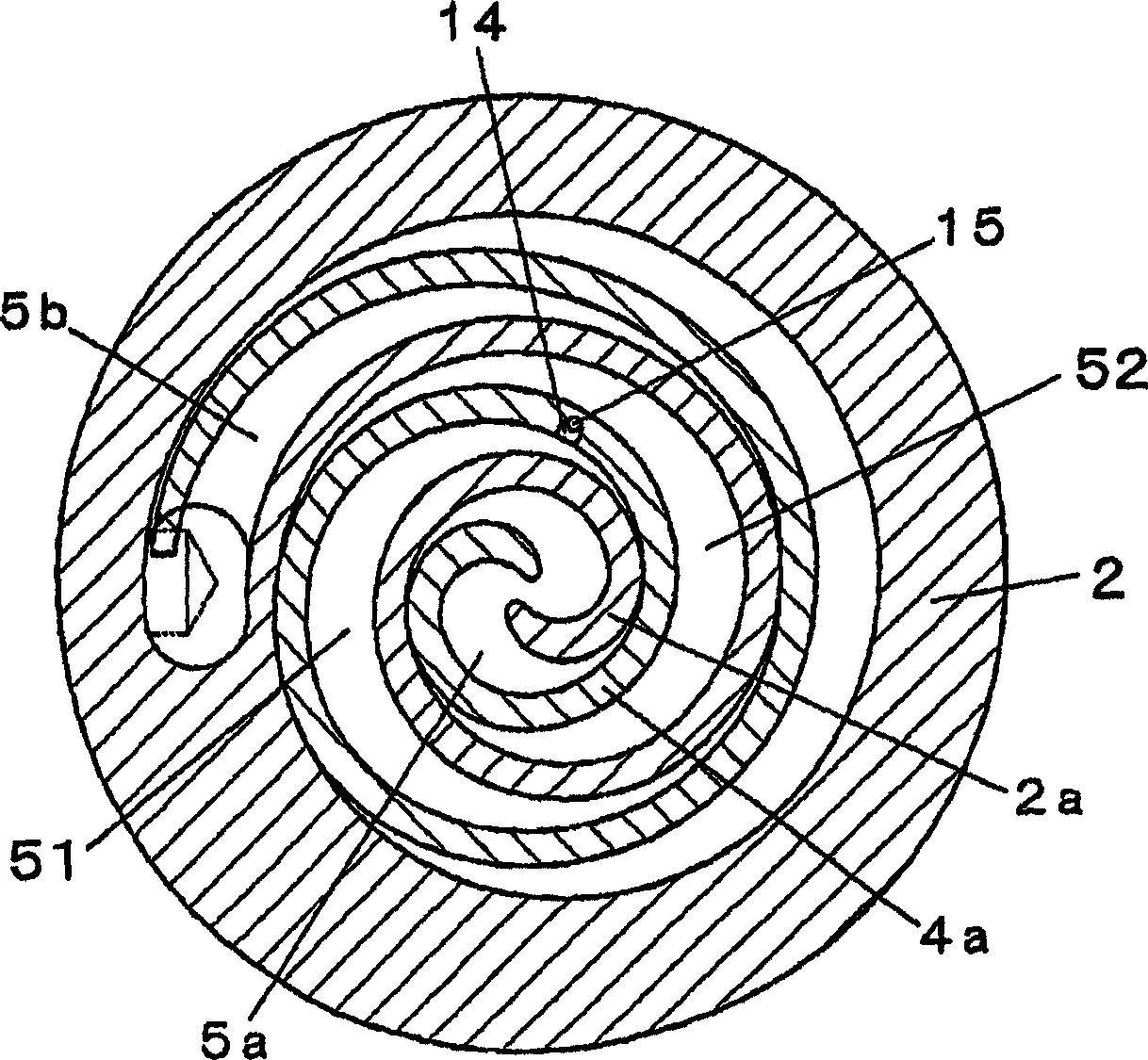

[0031] Figure 1-Figure 3 Indicates the first embodiment. In this figure, in order to clarify the difference between the scroll compressor of this embodiment and the conventional scroll compressor, Figure 7 Components that are identical or functionally equivalent are marked with the same symbols. Lubricating oil stored in the lower portion of the hermetic container passes through a passage 13A formed inside the shaft 13 , is depressurized by an orifice 12 mounted in the orbiting scroll 4 , and is supplied to the back pressure chamber 8 . In addition, a recessed portion 14 is provided at the front end of the wrap portion 4 a of the orbiting scroll member 4 , and a communicating passage 15 is provided that communicates between the recessed portion 14 and the rear surface of the mirror plate 4 b. In addition, in this embodiment, since the suction pipe 1 and the suction chamber 3 overlap with the back pressure adjustment mechanism 9, they are conveniently divided into left and r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com