Battery and method of manufacturing the battery

A manufacturing method and battery technology, applied in secondary battery manufacturing, battery pack parts, final product manufacturing, etc., can solve problems such as separation of circuit board and secondary battery, resin peeling, resin and secondary battery buckle, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

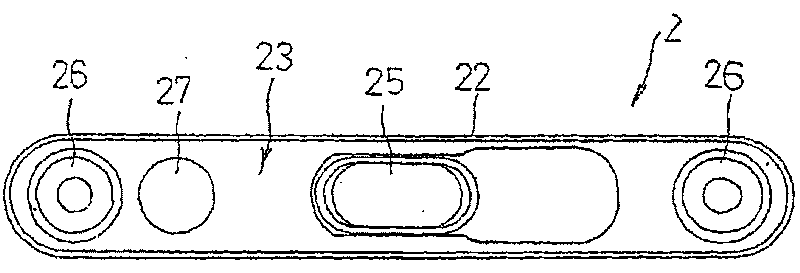

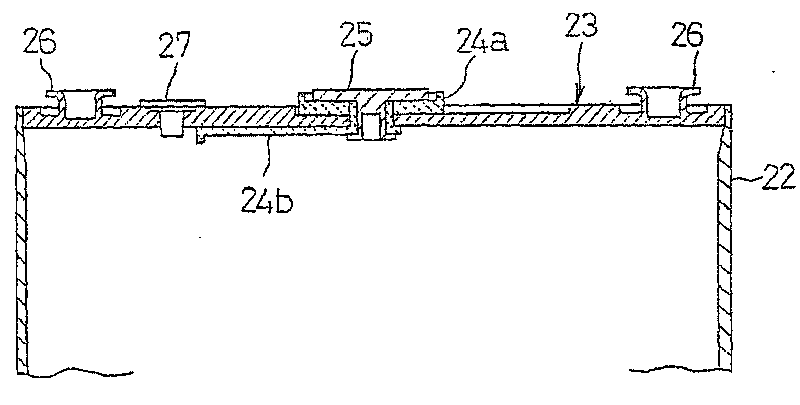

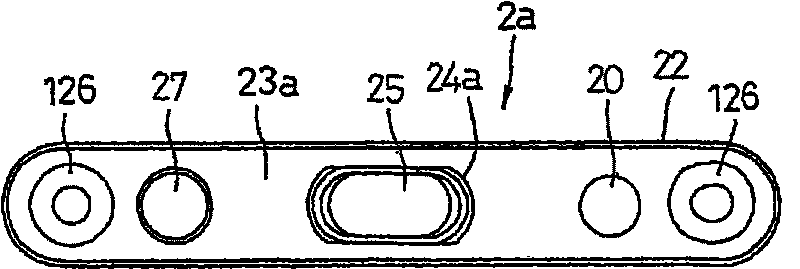

[0041] Embodiments of the present invention will be described below with reference to the drawings for understanding of the present invention. In addition, the embodiment shown below is an example which actualized this invention, and does not limit the technical scope of this invention.

[0042] In the example shown in this embodiment, a circuit board constituting a battery protection circuit and the like is filled with resin and integrated with a flat rectangular lithium-ion secondary battery to form a battery pack suitable for a mobile phone. Battery packs suitable for mobile phones are not only required to have small size, light weight, and thin thickness, but also have high energy density suitable for multi-functionality, and mechanical strength that can withstand the impact caused by dropping, etc., which is inevitable as a portable device. The structure that is not easily disassembled, and the safety function of protecting the secondary battery from short circuit, overch...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com