Preparation method of oligomeric phosphonate flame retardant

The technology of polyphosphonate and flame retardant is applied in the field of preparation of oligomeric phosphonate flame retardant, which can solve the problems of containing alkali metal ions and high organic tin acid value, and achieve excellent thermal stability and flame retardant performance. Excellent, avoid core burning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

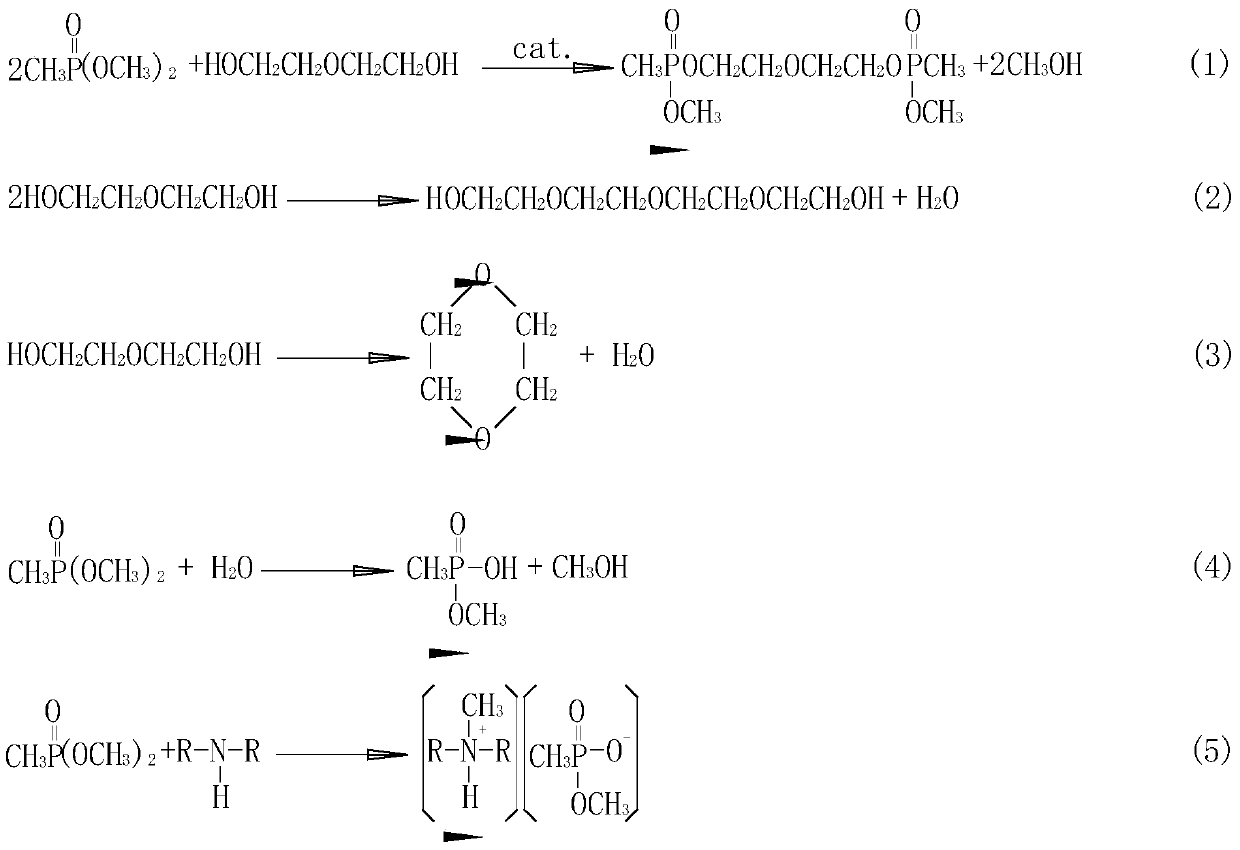

Method used

Image

Examples

Embodiment 1

[0043] Add 114g of tetraethyl titanate and 106g of diethylene glycol into a reactor equipped with a thermometer, a magnetic stirrer and a distillation device, start stirring, heat in an oil bath, and gradually increase the temperature, at 70-96°C, 0.03-0.08MPa vacuum Under the condition of 3h, 90g of ethanol was evaporated while reacting, and the residue was cooled to obtain 130g of bis(diethylene glycol) titanate. The appearance was a colorless transparent viscous liquid, and 130g of dimethyl methylphosphonate Dilute and mix to obtain 260 g of 50% bis(diethylene glycol) titanate solution, code-named TDEG, for use in the following experiments.

[0044] In a 500mL reactor equipped with a thermometer, a stirrer and a vacuum distillation device, add 372g of dimethyl methylphosphonate, 106g of diethylene glycol and 10g of TDEG, stir, heat, and under nitrogen protection, gradually increase the temperature and gradually reduce the vacuum Control the reaction temperature at 120-180°C...

Embodiment 2

[0046] In a 500mL reactor equipped with a thermometer, a stirrer and a vacuum distillation device, add 372g of dimethyl methylphosphonate, 106g of diethylene glycol and 10g of TDEG, stir, heat, and under nitrogen protection, gradually increase the temperature and gradually reduce the vacuum Control the reaction temperature at 120-180°C, vacuum degree 0-0.06MPa, and distill the by-product methanol while reacting within 6 hours. After the exchange reaction was completed, 57.6 g of methanol was recovered. Keep the temperature at 180°C, gradually increase the degree of vacuum to above 0.095MPa, and distill off excess dimethyl methylphosphonate under reduced pressure. When the rate of distillate is obviously slow, stop vacuuming, continue to pass nitrogen to restore normal pressure, and recover 126.6 g of dimethyl methylphosphonate were used to obtain 303.8 g of a crude product with an acid value of 12.6 mgKOH / g. Cool the crude product to 115°C, add 15g of 1,4-butanediol diglycidy...

Embodiment 3

[0048] In a 500mL reactor equipped with a thermometer, a stirrer and a vacuum distillation device, add 372g of dimethyl methylphosphonate, 106g of diethylene glycol and 14.3g of TDEG, stir, heat, and gradually raise the temperature and gradually lower the temperature under the protection of nitrogen. Vacuum degree, control the reaction temperature at 120-180°C, vacuum degree 0-0.06MPa, and distill the by-product methanol within 5h while reacting. After the transesterification reaction was completed, 60.8 g of methanol was recovered. Keep the temperature at 180°C, gradually increase the degree of vacuum to above 0.095MPa, and distill off excess dimethyl methylphosphonate under reduced pressure. When the rate of distillate is obviously slow, stop vacuuming, continue to pass nitrogen to restore normal pressure, and recover 133.6 g of dimethyl methylphosphonate were used to obtain 298.6 g of a crude product with an acid value of 8.6 mgKOH / g. Cool the crude product to 115°C, add 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com