Heat-radiating device of electric component

A technology for electronic components and heat sinks, applied in the field of heat sinks for electronic components, can solve the problems that semiconductor LED lighting sources cannot be widely used, the service life of chips is reduced, and the heat sinks are bulky, etc. The effect of reducing impedance and improving heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The structure and operating principle of the heat sink for electronic components of the present invention will be further described in detail below in conjunction with the accompanying drawings.

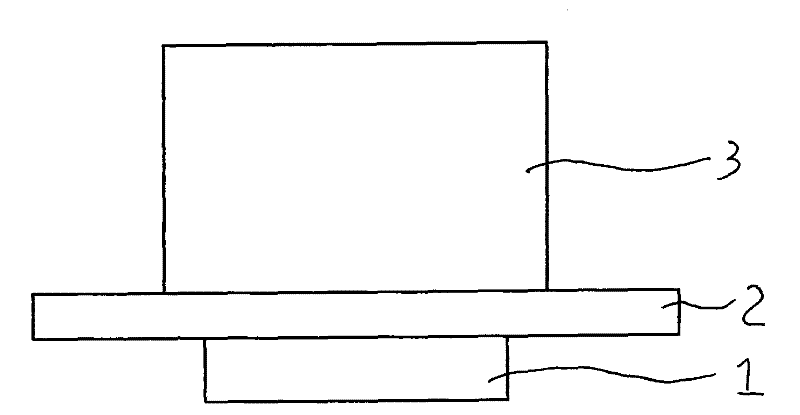

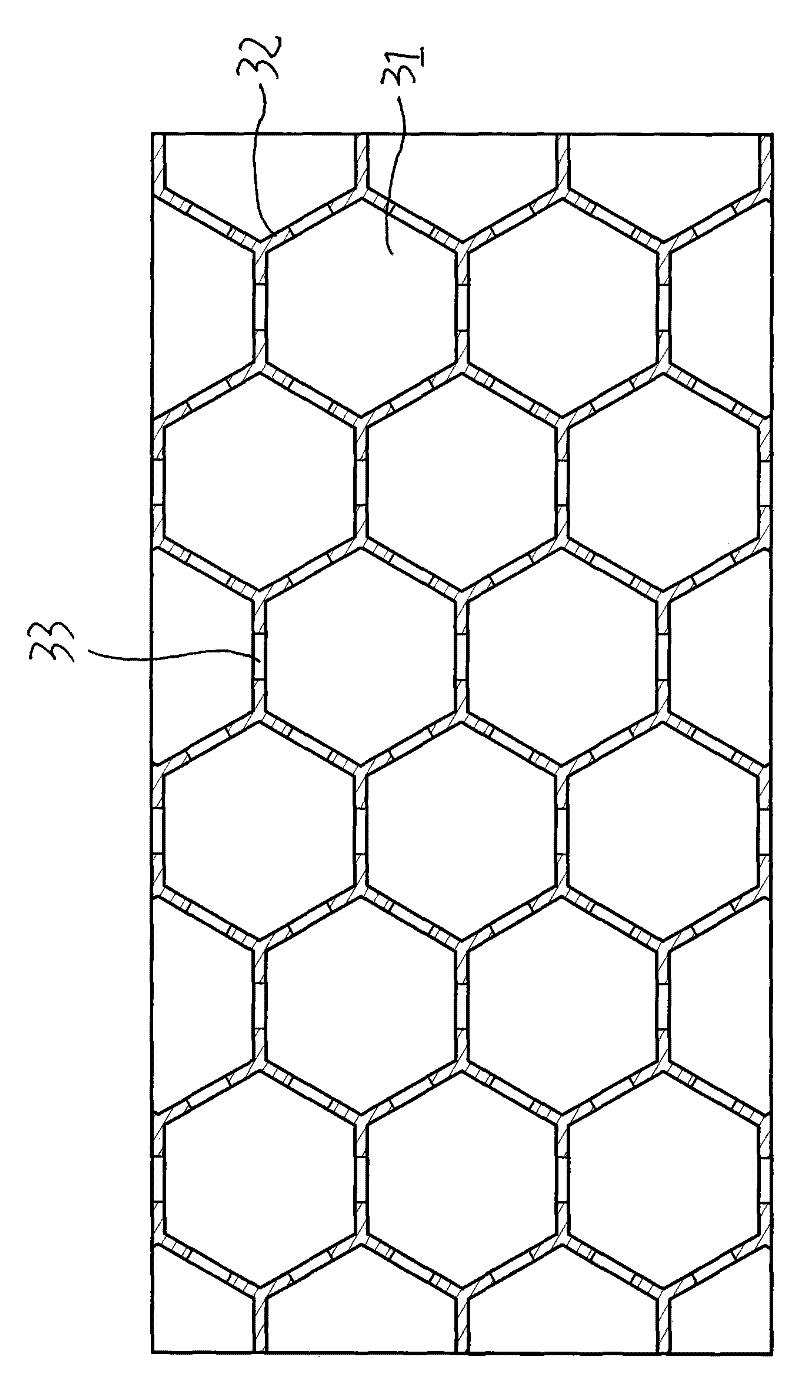

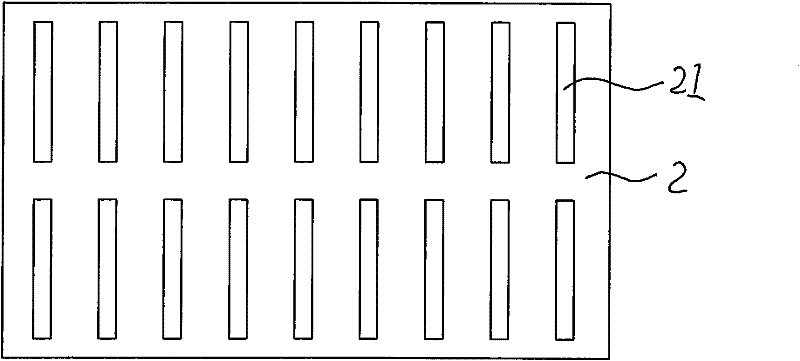

[0015] Such as figure 1 and figure 2 As shown, the heat dissipation device for electronic components of the present invention includes a heat dissipation substrate 2 and a heat dissipation fin 3. The heat dissipation substrate 2 and the electronic components 1 are tightly bonded together through a heat-conducting adhesive. The channel 31 and the heat dissipation wall 32 surrounding the heat dissipation channel 31 are composed. The cross section of the heat dissipation channel 31 is a regular hexagon, and the cross section of the heat sink 3 is honeycomb. The heat dissipation channel 31 forms air convection, and the heat dissipation method is mainly changed from radiation to convection. Mainly, supplemented by radiation, the thermal impedance of the heat dissipation channel i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com