Bolt-assembled double-layer aluminum alloy reticulated shell structure

A technology of aluminum alloy mesh and shell structure, which is applied to arch structures, dome structures, building components, etc., can solve the problems of small distance between the upper and lower layers of rods, reduced material utilization, and weak joint shear stiffness. Achieve the effects of improving overall stability, improving material utilization, and enriching node forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described below in conjunction with the accompanying drawings and embodiments.

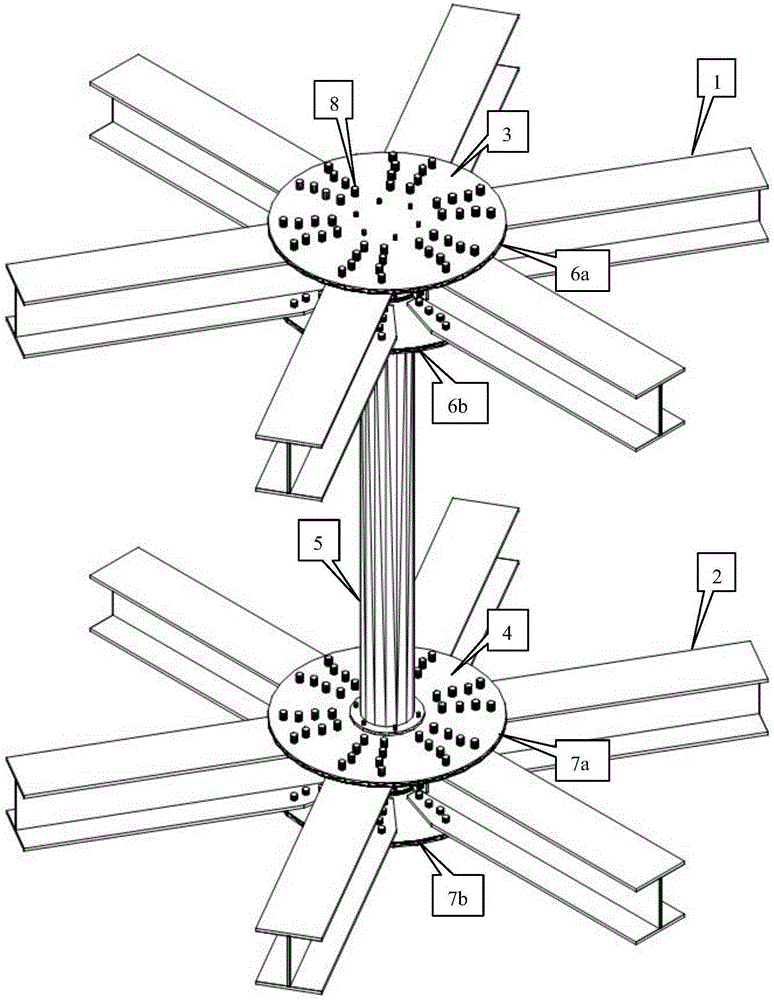

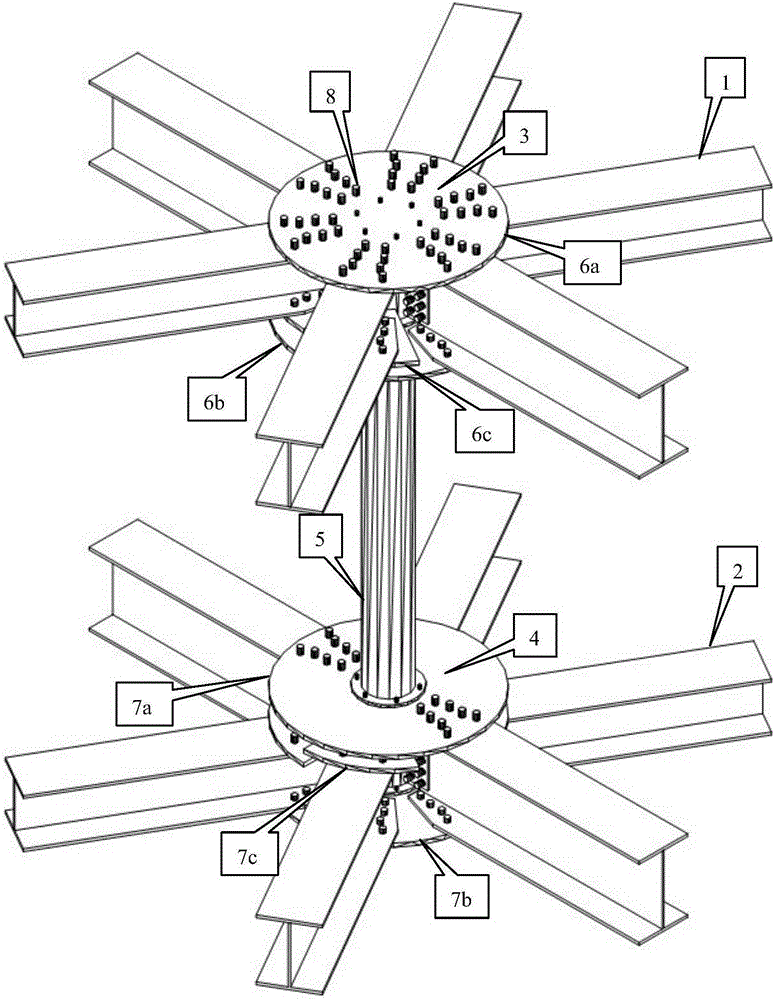

[0027] Such as figure 1 , figure 2 and image 3 As shown, the bolt-assembled double-layer aluminum alloy reticulated shell structure in this embodiment includes the upper H-shaped aluminum alloy rod 1, the lower H-shaped aluminum alloy rod 2, the upper bolt assembly node 3, the lower bolt assembly node 4, and the vertical aluminum alloy rod. Round web bar 5 and bolt 8. In the present invention, the upper bolt assembly node 3 and the lower bolt assembly node 4 are basically the same in structure, the main difference is that the former is located at the upper part of the vertical aluminum alloy round web bar 5, and the latter is located at the lower part of the vertical aluminum alloy round web bar 5 .

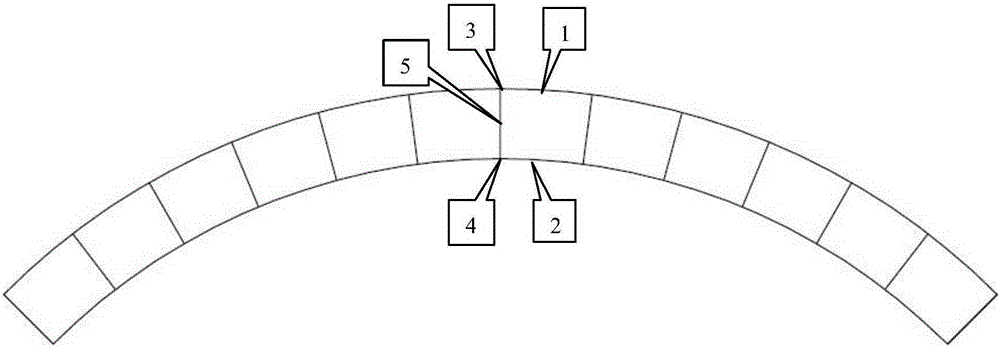

[0028] The arrangement of the upper H-shaped aluminum alloy rod 1 and the lower H-shaped aluminum alloy rod 2 of the bolt-assembled double-layer aluminum al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com