Insulation curtain wall and its construction method

A construction method and technology of thermal insulation curtain, applied in the direction of thermal insulation, wall, building components, etc., can solve the problems of different structure, no thermal insulation curtain wall, comprehensive environmental protection performance to be improved, etc., to save aluminum, the construction method is simple and efficient, The effect of reducing construction costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

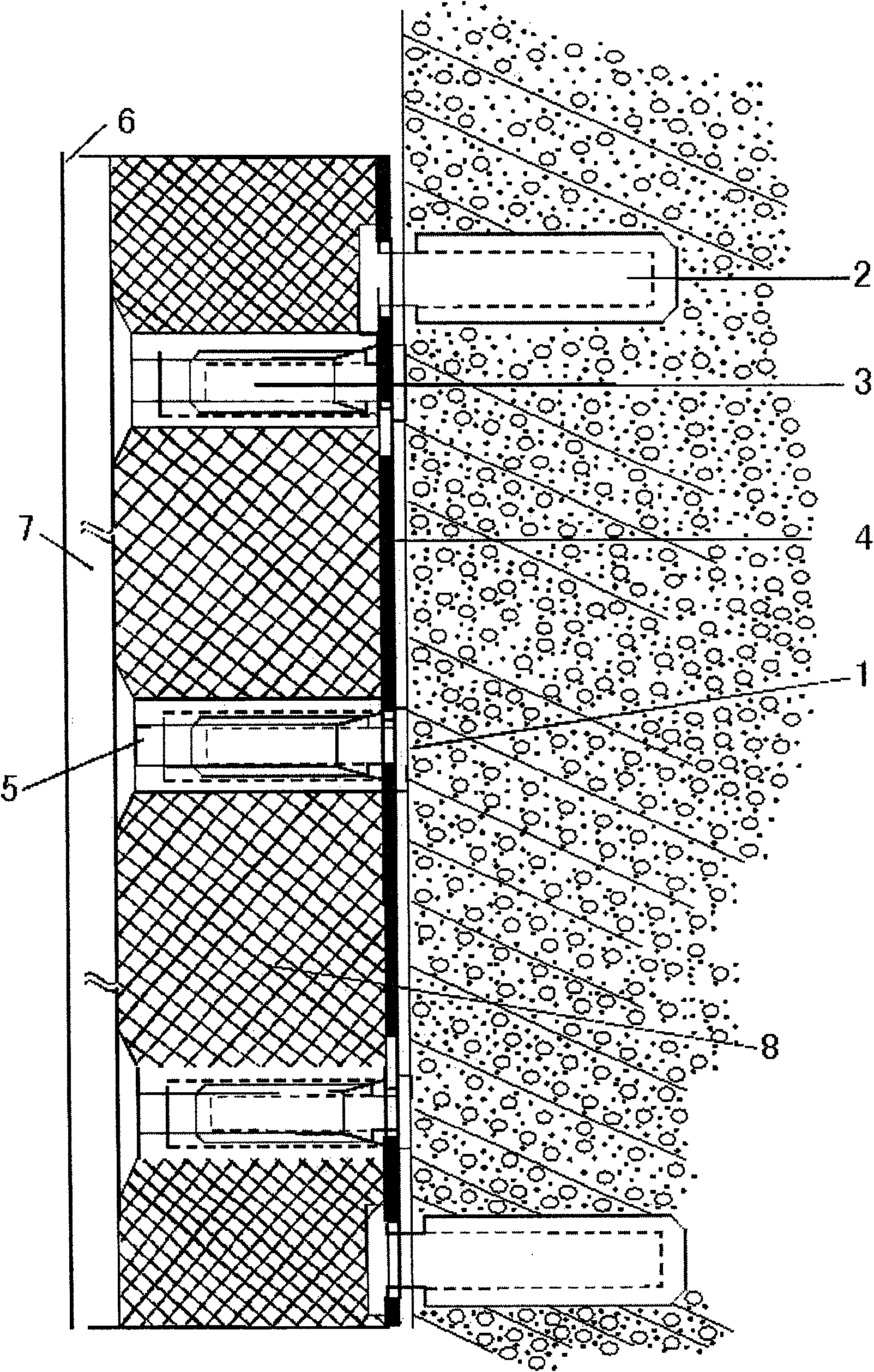

[0038] Such as figure 1 The shown one is used for a thermal insulation curtain wall of a center main building, including expansion bolts 2, hanging panels 4, gusset panels 7, and thermal insulation panels 8.

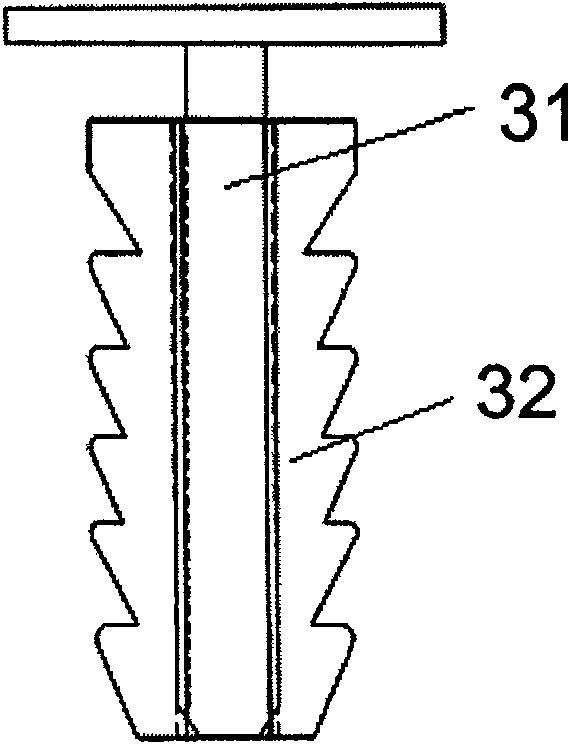

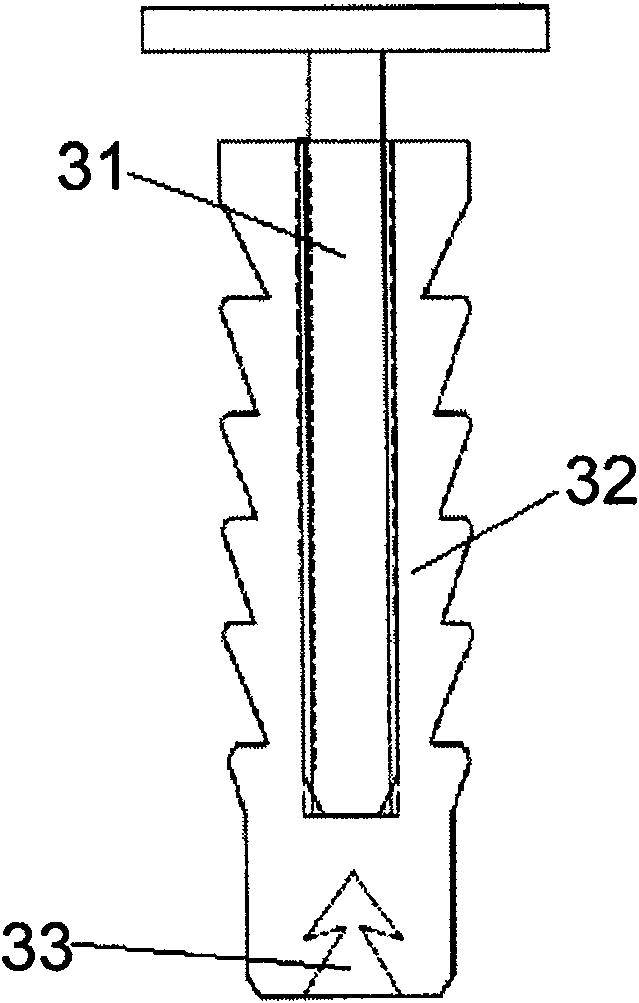

[0039] Expansion bolts 2 are pre-embedded in the outer wall 1 . The hanging plate 4 is preset with an undercut bolt 3, the hanging plate 4 is installed on the surface of the outer wall 1 through the expansion bolt 2, and the buckle plate 7 is fastened on the outside of the hanging plate 4 through the cooperation of the countersunk lock post 5 and the undercut bolt 3.

[0040] The insulation board 8 is preset with through holes matching the undercut bolts 3 , the through holes of the insulation board are covered outside the undercut bolts 3 , and the insulation board 8 is arranged between the buckle plate 7 and the hanging plate 4 .

[0041] The height and diameter of the undercut bolt 3 match the height and diameter of the inner space of the countersunk lock post 5 on t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com