A kind of anode steel claw guide rod group

A technology of anode steel claw and guide rod, which is applied to the field of anode steel claw guide rod group, can solve the problems of large consumption of aluminum/steel explosive welding block, small size of aluminum/steel explosive welding block, short service life, etc. Conducive to environmental protection, reduced material costs, and low manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

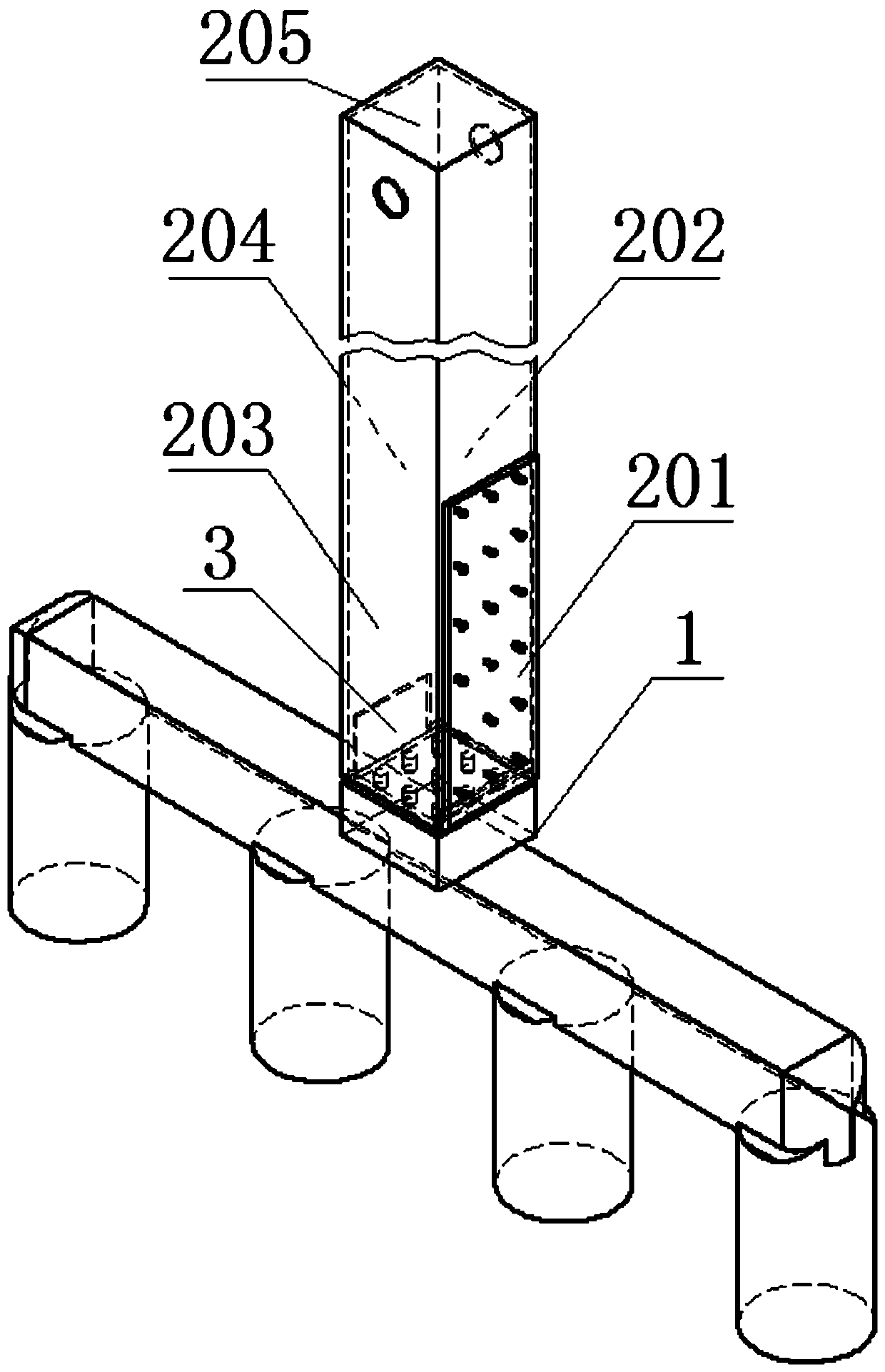

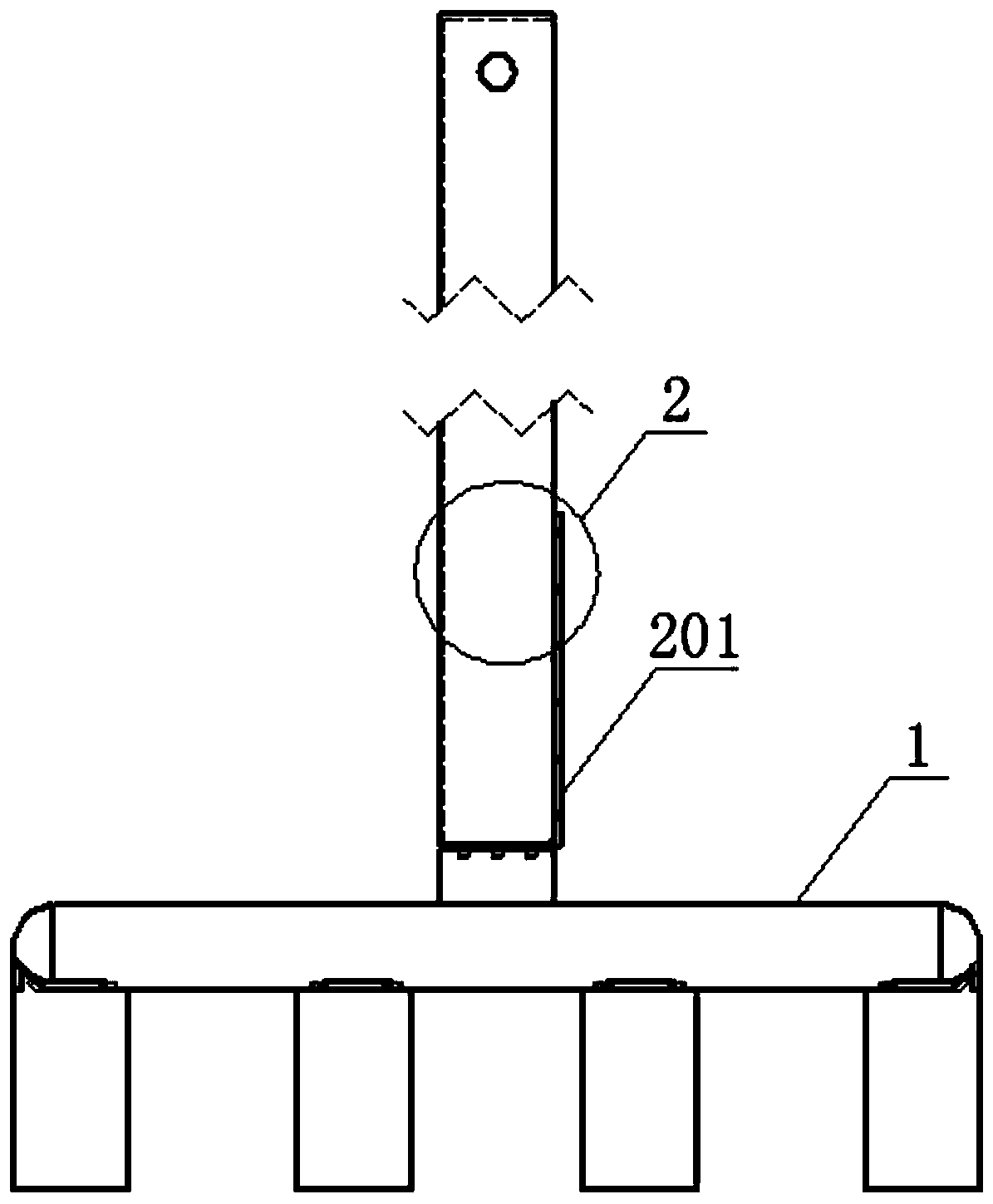

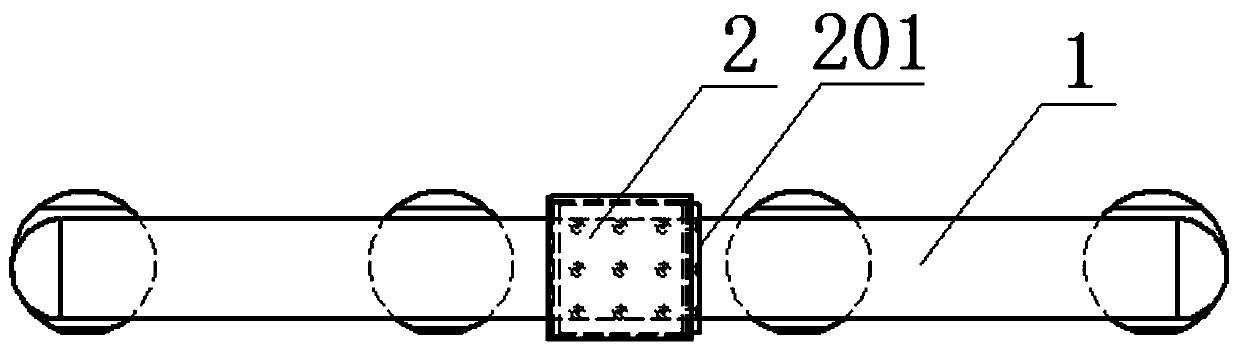

[0022] A kind of anodized steel claw guide rod set, such as figure 1 , figure 2 , image 3 and Figure 4 As shown, including the anode steel claw guide rod 2 and the anode steel claw 1, the anode steel claw guide rod 2 is provided with a hoisting part, and a good conductor plate 201 with a thickness of 22 mm is used (the thickness of the good conductor plate 201 in this embodiment is selected to be 22mm copper plate) and four steel plates (202, 203, 204, 205) with a thickness of 8mm that meet the strength requirements form a frame structure with a hollow bottom as the anode steel claw guide rod 2 directly connected to the top surface of the anode steel claw 1; good conductor The plate 201 (copper plate) is attached to one side of the anode steel claw guide rod 2, the steel plates (202, 203, 204) are located on the other three sides of the anode steel claw guide rod 2, and the steel plate 205 is located on the top surface of the anode steel claw guide rod 2, wherein , the s...

Embodiment 2

[0028] An anode steel claw guide rod group, comprising an anode steel claw guide rod and an anode steel claw, a hoisting part is arranged on the anode steel claw guide rod, and a good conductor plate with a thickness of 25mm is used (in this embodiment, the thickness of the good conductor plate is selected to be 25mm copper alloy plate) and four steel plates with a thickness of 6mm that meet the strength requirements form a frame structure with a hollowed out bottom as the anode steel claw guide rod directly connected to the top surface of the anode steel claw; the copper alloy plate is attached to the anode steel claw guide On one side of the rod, the steel plates are located on the other three sides of the anode steel claw guide rod and the top surface of the anode steel claw guide rod, and the bottom of the steel plate and the bottom of the good conductor plate on the side of the anode steel claw guide rod are directly welded and connected to the top surface of the anode stee...

Embodiment 3

[0034] A kind of anode steel claw guide rod group, comprise anode steel claw guide rod and anode steel claw, the anode steel claw guide rod is provided with hoisting part, adopts a piece of silver plate that thickness is 15mm (that is, good conductor plate selects the silver plate that thickness is 15mm Plate) and three steel plates with a thickness of 12mm that meet the strength requirements enclose a rectangular frame structure with a hollowed out bottom as the anode steel claw guide rod directly connected to the top surface of the anode steel claw; the silver plate is attached to one side of the anode steel claw guide rod, and the steel plate It is located on the adjacent side of the silver plate and the top surface of the anodized steel claw guide rod, and the opposite side of the silver plate is hollowed out. When in use, the silver plate is connected to the busbar.

[0035] As preferably, the hoisting part is located on the top surface of the anode steel claw guide rod, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com