Holographic graphic gravure positioning printing method

A graphic and holographic technology, applied in printing, printing devices, etc., can solve the problems of high equipment accuracy and operator level requirements, difficulty in meeting high-precision positioning anti-counterfeiting, and low positioning accuracy, and achieve strong anti-counterfeiting effects and good molding performance , good folding resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] S1: Plate making process, making laser plates with graphic information;

[0028] S2: Coating process, using coating equipment to uniformly and densely coat a layer of release agent or imaging coating on the PET base film; the thickness of the release agent or imaging coating coated on the PET base film is 1.0 ~1.5g / m 2 .

[0029] S3: Aluminum plating process, the PET base film coated with a release agent or imaging coating on the surface and the aluminum material are installed in a vacuum evaporation machine, and the vacuum evaporation machine is vacuumed with a vacuum pump, and then the aluminum material is Heating to 1200°C-1400°C, so that the gaseous aluminum particles are deposited on the surface of the moving release agent or imaging coating, and then cooled to form a continuous and bright metal aluminum layer; the vacuum pump pumps the vacuum evaporation machine The vacuum degree of the vacuum should reach 1.3×10 -2 ~1.3×10 -3 pa. The thickness of the aluminu...

Embodiment 2

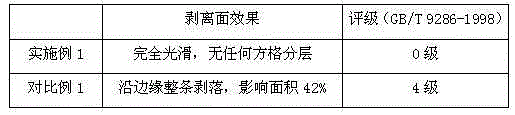

[0035] Scratch test of embodiment 2 finished transfer paper

[0036] Using the holographic transfer paper prepared in Example 1 (that is, the paper that has not passed through the gravure printing process), it is carried out with a cross-cut knife test according to the national standard GB / T9286-1998, and the transfer layer on the surface of the test product is scratched 10 times with a cross-cut knife. ×10 (100 pieces) 1mm×1mm small grid, the depth of the line and the bottom layer of the coating material; use a brush to clean the debris in the test area; stick the tested grid with 3M600 adhesive tape, and use an eraser to force it Wipe the tape to increase the contact area and strength between the tape and the measured area; grasp one end of the tape, quickly tear off the tape in the vertical direction (90°), and observe the situation where the coating in the grid is pulled off by the tape, the same position Conduct the same adhesion test twice, and the results after three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com