Novel aluminum formwork

A technology of aluminum formwork and formwork, which is applied in the fields of formwork/formwork components, joints of formwork/formwork/workframes, and on-site preparation of building components. Problems such as moulds, to achieve the effect of reducing construction costs, increasing turnover times, and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

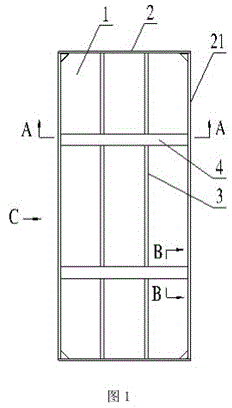

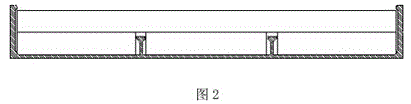

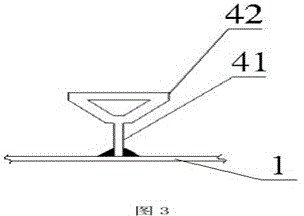

[0020] After multiple aluminum formworks are connected during construction work (such as Figure 8 Shown) in contact with concrete grout, the specific structure of the aluminum formwork is as 1- Figure 6 As shown, it includes a panel 1 and a connecting plate 2 located around the inner side of the panel. The inner side of the panel 1 is provided with several longitudinal reinforcing ribs 3 and transverse reinforcing ribs 4 that are fixedly connected to the connecting plate at both ends, and the transverse reinforcing ribs 4 include fixedly connected The notch strip 41 and the stressed rib 42, the side where the transverse reinforcing rib 4 is in contact with the panel, that is, the side where the notch strip 41 is in contact with the panel, is provided with a notch 43, and the longitudinal reinforcing rib 3 is inserted into the notch 43, The t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com