Horizontal current aluminium cell

An aluminum electrolytic cell and horizontal current technology, which is applied in the field of electrolytic cell structure, can solve problems such as fluctuations in the aluminum liquid layer, complex busbar structure, and reduced production efficiency of aluminum electrolysis, and achieve long service life, material saving, and good social and economic benefits Effect

Inactive Publication Date: 2008-11-19

HENAN ZHONGFU IND

View PDF0 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The capacity of the electrolytic cell is large, and the structure of the busbars entering and exiting the electrolytic cell is complex, so that there will be magnetic fields in different directions, in which the magnetic field generated by the horizontal current will interact with the magnetic field generated by the vertical current in the aluminum liquid, causing the aluminum liquid layer to fluctuate. Resulting in lower production efficiency of aluminum electrolysis

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

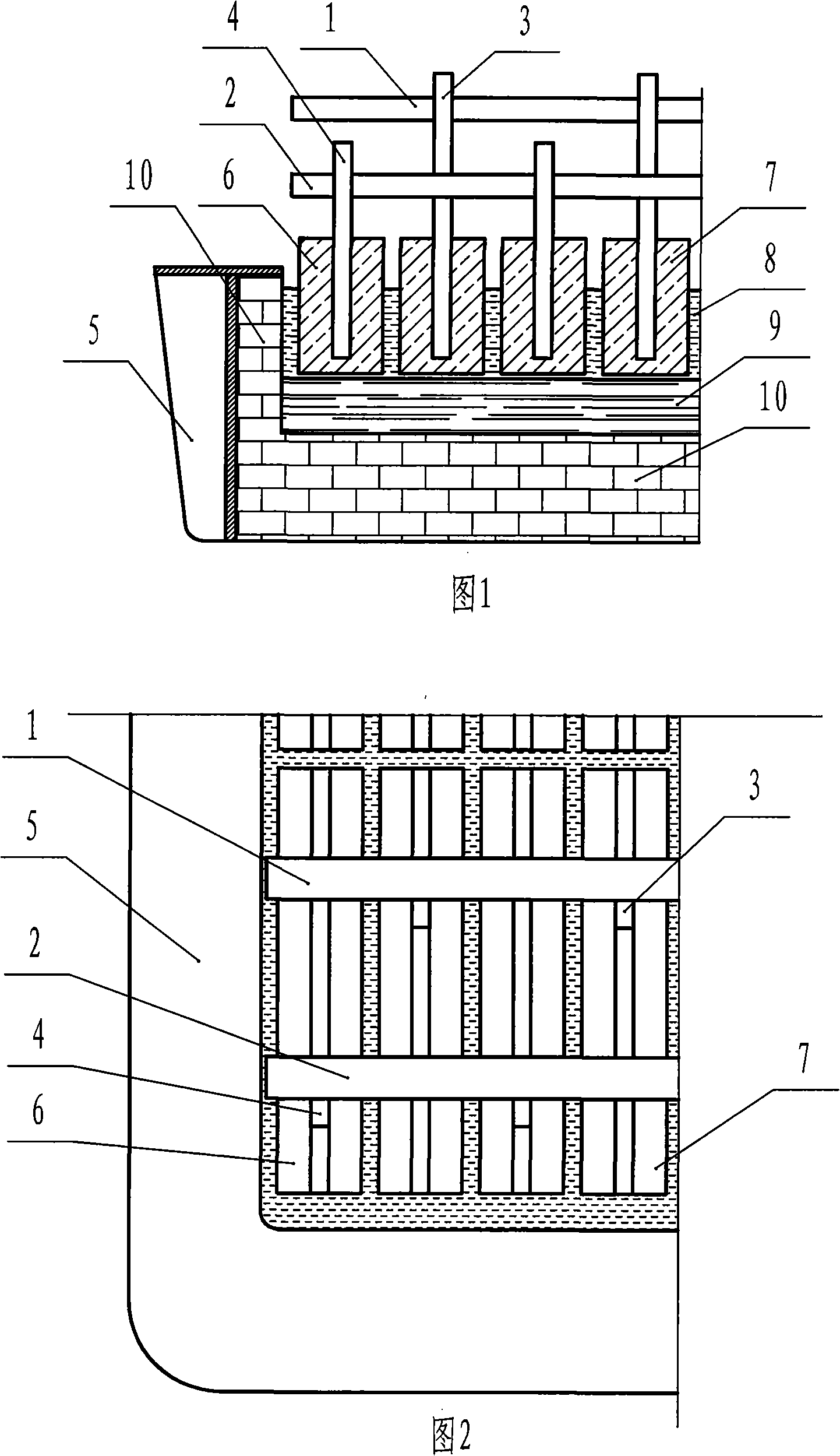

The invention discloses a horizontal current aluminum electrolytic bath. The aluminum electrolytic bath comprises a melting bath part and an electrode part, wherein the melting bath part consists of a steel bath shell(5) and fire proof and heat proof materials(10); the upper end of the bath shell(5) adopts an open type structure; while the electrode part consists of a cathode electrode part and an anode electrode part, wherein the cathode electrode part consists of a cathode electrode(6), a cathode electrically conductive pole(4) and a cathode bus(2) applied to discharge electric current, and the anode electrode part consists of an anode electrode(7), an anode electrically conductive pole(3) and an anode bus(1) applied to charge electric current; the electrode part are hanged in the bath shell(5) by a support steel beam, and a liquid electrolyte layer (8) is arranged between the cathode electrode(6) and the anode electrode(7); electrolytic currents horizontally enter the corresponding side face of the cathode electrode(6) from the side face of the anode electrode(7). The aluminum electrolytic bath has the advantages that the design is novel, no electric current pass through the melting bath, no electrochemical reaction happens, the aluminum electrolytic bath does not need to be drilled around, along with long service life and good social and economic benefits.

Description

Horizontal current aluminum electrolytic cell Technical field: The invention relates to an aluminum electrolytic cell, in particular to a horizontal current aluminum electrolytic cell, which belongs to the field of electrolytic cell structures. Background technique: At present, the direction of the electrolytic current in the electrolytic cell used in the production of electrolytic aluminum industry is vertical, that is, the current flows from the anode at the upper part of the electrolytic cell vertically to the cathode at the bottom. The problems that exist in this way are: 1. A strong current of hundreds of thousands of amperes flows through the bottom of the molten pool of the electrolytic tank. Under the action of electrochemical reaction, the carbon cathode at the bottom expands and breaks, which keeps the life of the electrolytic tank at about 1800 days. 2. The electrolytic cell passes through a strong current of hundreds of thousands of amperes, which will gener...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C25C3/08

Inventor 梁学民王有山

Owner HENAN ZHONGFU IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com