Patents

Literature

52results about How to "Play the role of defoaming" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

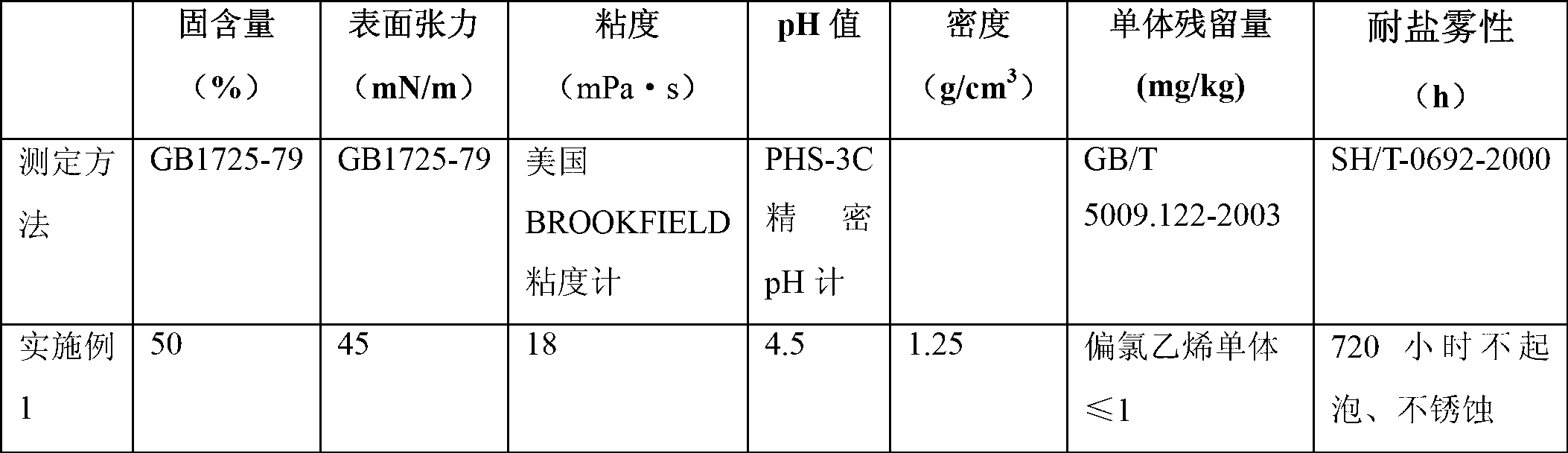

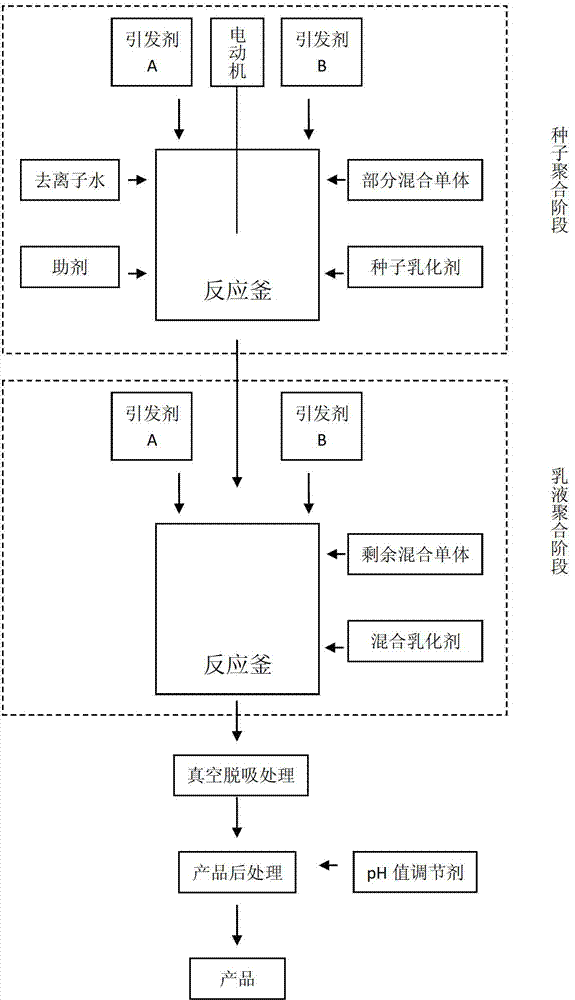

Aqueous antiseptic metal undercoat polyvinyl dichloride (PVDC) copolymer emulsion and preparation method thereof and application

ActiveCN103059197ALow costThe synthesis process is simpleAnti-corrosive paintsVolatile organic compoundEmulsion

The invention discloses an aqueous antiseptic metal undercoat polyvinyl dichloride (PVDC) copolymer emulsion and a preparation method thereof and application, and aims at solving the problems that an existing solvent type undercoat used for metal corrosion prevention is harmful to a human body and easily causes environmental pollution and the like. Vinylidene chloride, (methyl) acrylic esters, acrylonitrile and crylic acid are used as mixing monomers, seeded emulsion polymerization is adopted to obtain the aqueous antiseptic metal undercoat PVDC copolymer emulsion, the aqueous antiseptic metal undercoat PVDC copolymer emulsion is low in cost, simple in synthetic process, low in content of volatile organic compounds, environment-friendly, pollution-free, good in corrosion prevention performance of obtained metal undercoat, and capable of replacing the existing solvent type undercoat and being used for corrosion prevention of metal surface.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Degreasing agent used for workpieces, preparation method and workpiece surface spraying pretreatment method

ActiveCN108384645AGood degreasingImprove washing effectInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsAlcoholPretreatment method

The invention relates to a degreasing agent used for workpieces, a preparation method and a workpiece surface spraying pretreatment method. The degreasing agent includes 3-5% by mass of a component A,3-5% by mass of a component B and the balance of tap water or deionized water, wherein the component A includes deionized water, an inorganic base, a complexing agent and a compounded low-foam solubilizing surfactant, and a mass ratio of the deionized water to the inorganic base to the complexing agent to the compounded low-foam solubilizing surfactant is (65-70):(15-25):(1-2):(8-14); and the component B includes deionized water, a complexing dispersant, a corrosion inhibitor, a low-foam solubilizer, an end-capped / modified isomeric alcohol ether surfactant and a modified polyether, and a massratio of the deionized water to the complexing dispersant to the corrosion inhibitor to the low-foam solubilizer to the end-capped / modified isomeric alcohol ether surfactant to the modified polyetheris (50-70):(1-2):(0-5):(5-10):(8-15):(8-25). The degreasing agent provided by the invention can be used at room temperature during spraying, has an excellent degreasing effect, and does not generatea large amount of foam; and the method for preparing the degreasing agent and the workpiece surface spraying pretreatment method which uses the degreasing agent have simple operation, and are suitablefor mass production.

Owner:佛山科富科技有限公司

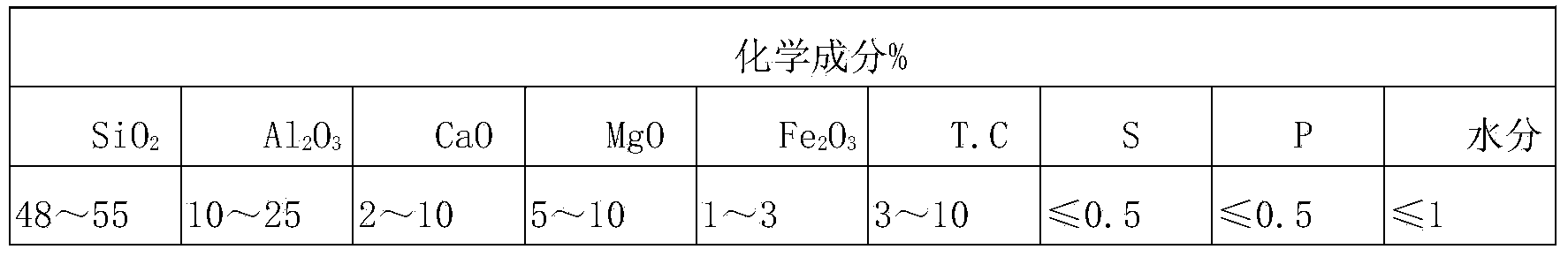

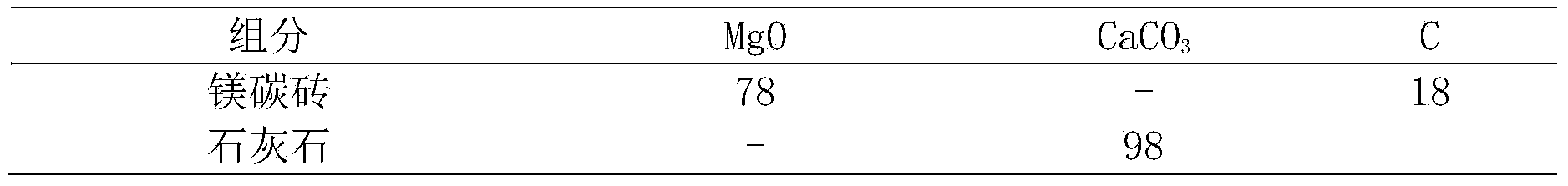

Production process of magnesian slag pressing agents

ActiveCN103484595AHigh melting pointIncrease liquid film viscosityManufacturing convertersSlagCarbide

The invention provides a production process of magnesian slag pressing agents. Magnesium-carbide refractory is cooled to 25-30 DEG C, crushed into 5-50mm particles by using a PC0606 jaw crusher, then placed in a 4R3216 Ramon mill, and machined into powder smaller than 3mm for standby application; limestone powder with the CaCO3 content being 98% is selected for standby application; the magnesium-carbide refractory powder and the limestone powder of which the mass percent is 65:35 are mixed, placed in a VI forced stirring mixer to be mixed evenly, then placed in a steel slag powder ball press machine or a refractory ball press machine to be made into 30+ / -5mm balls, and the balls are dried at the temperature of 30-50 DEG C and then can be used. The magnesian slag pressing agents are added 30-60s before a converter is toppled down at the smelting end point, and 25-35kg of the magnesian slag pressing agents are added to one ton of slag.

Owner:XINJIANG ZHONGHE DAZHENG COMMERCE & TRADE

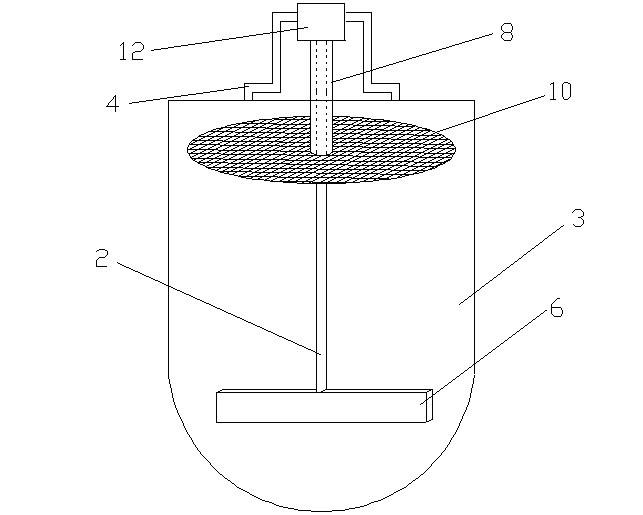

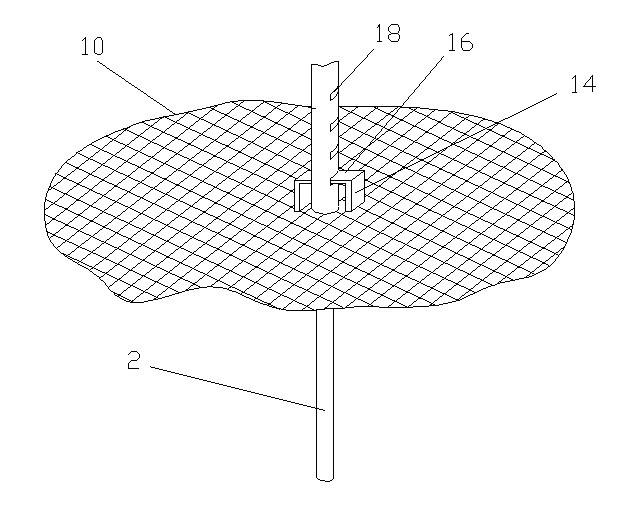

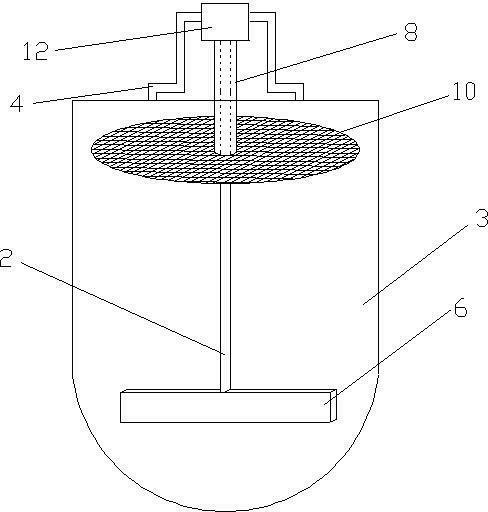

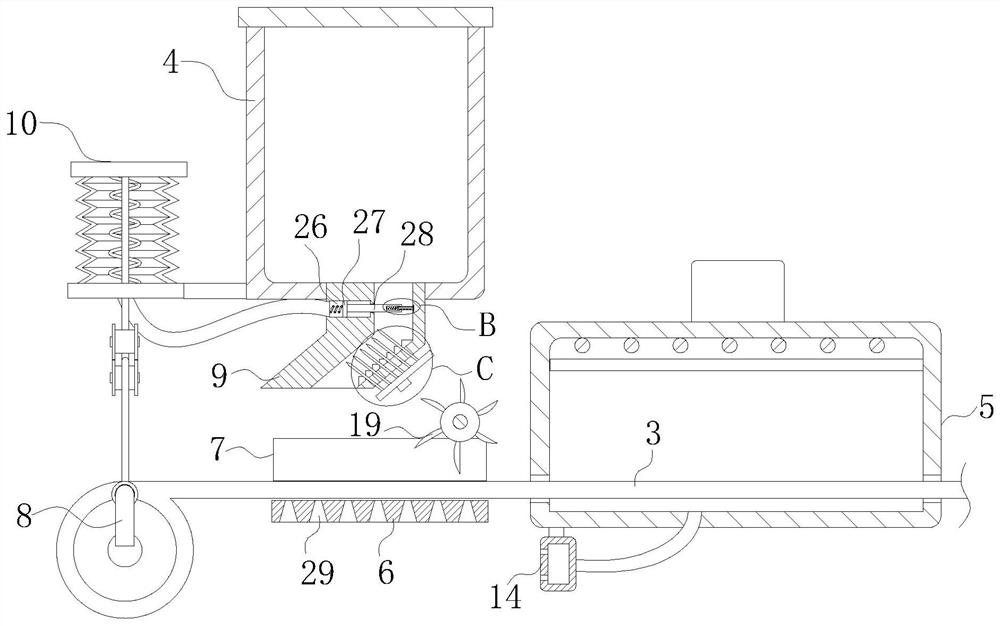

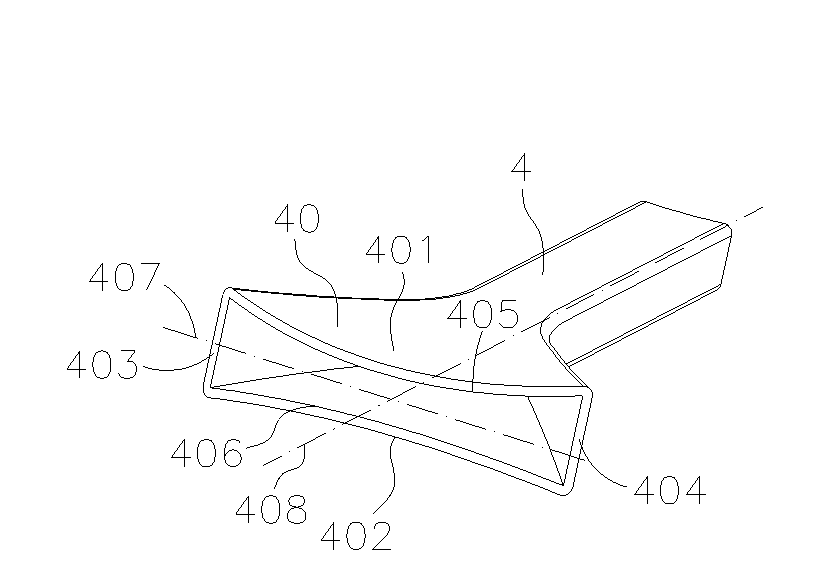

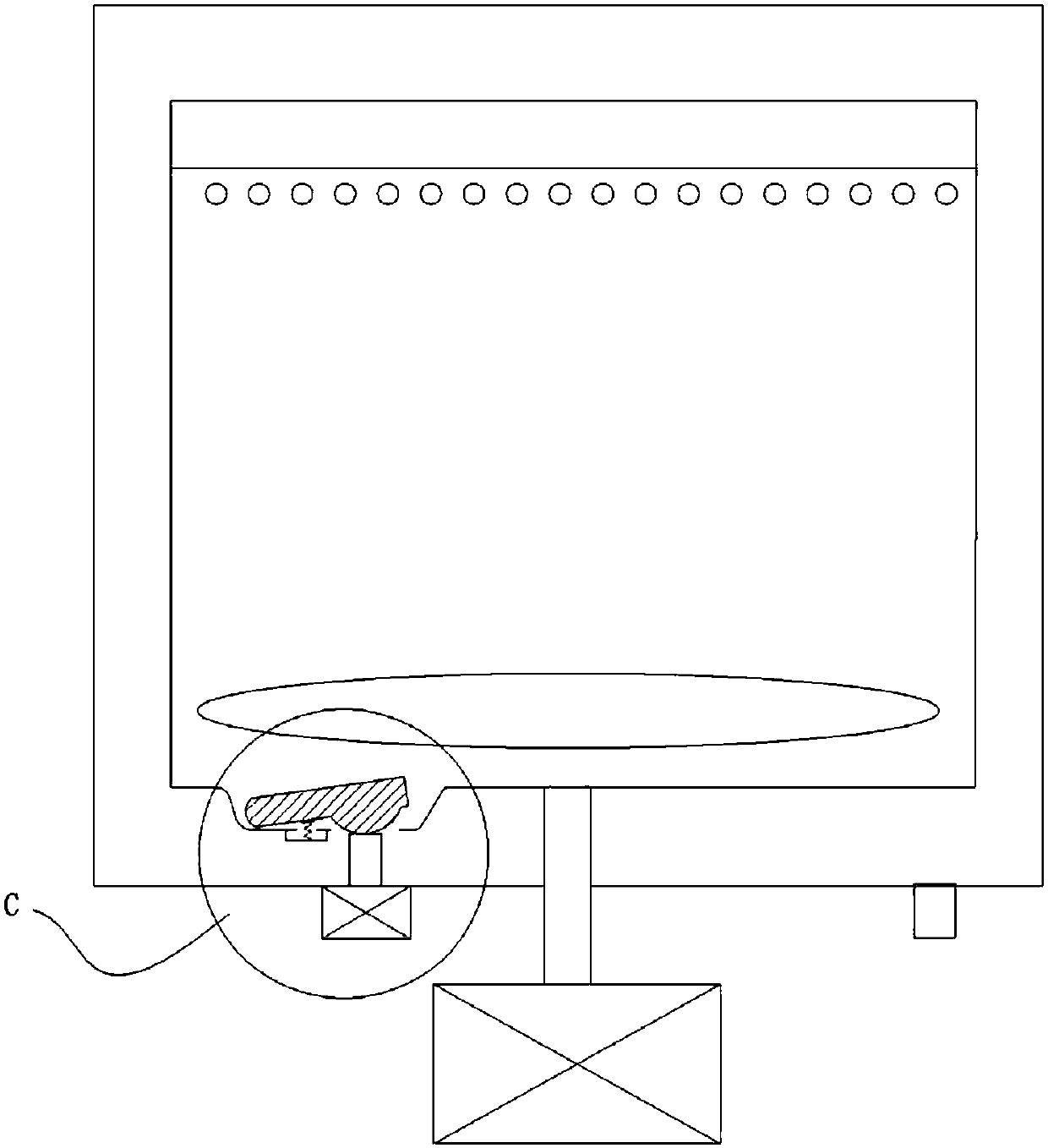

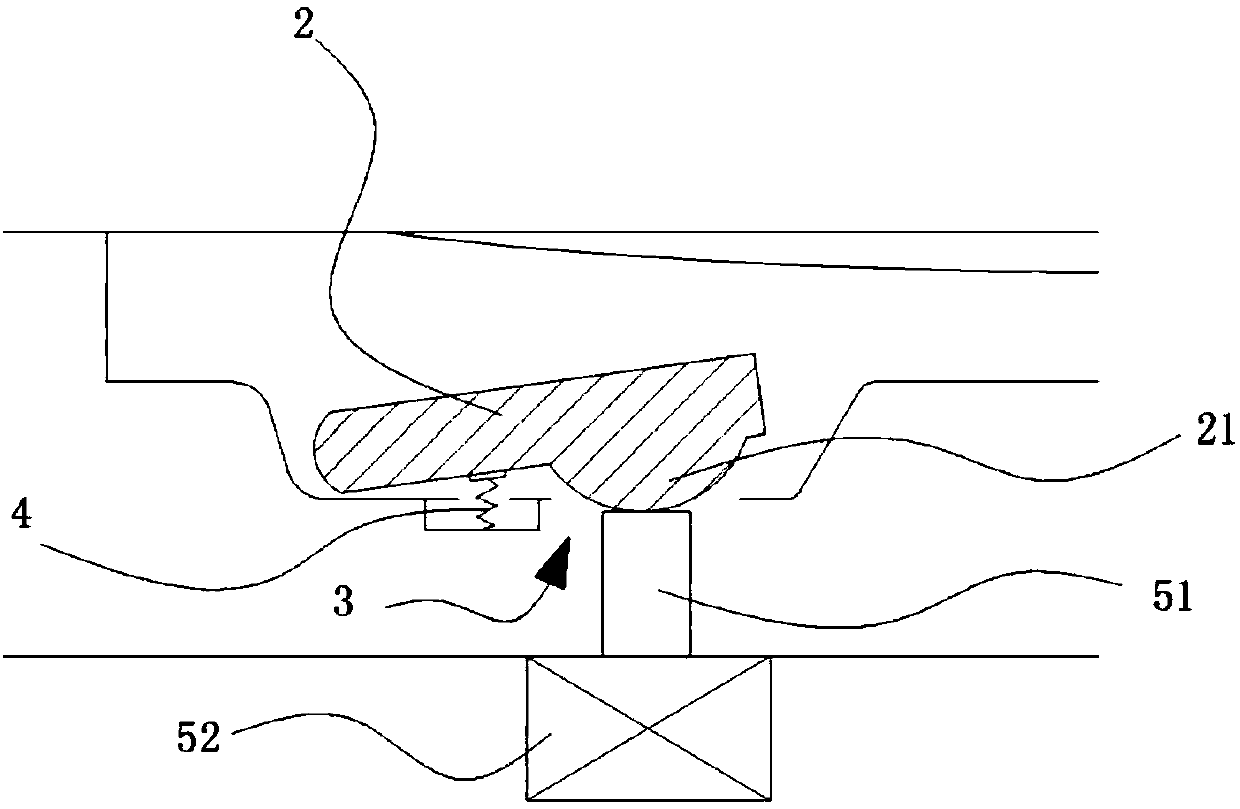

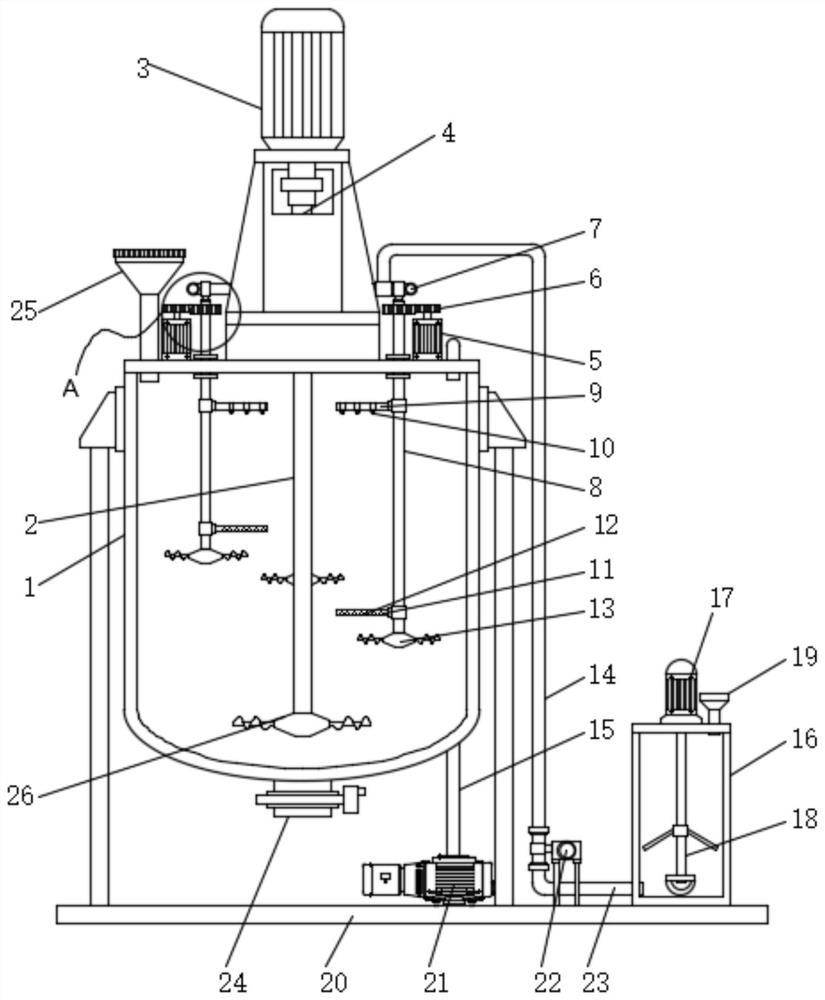

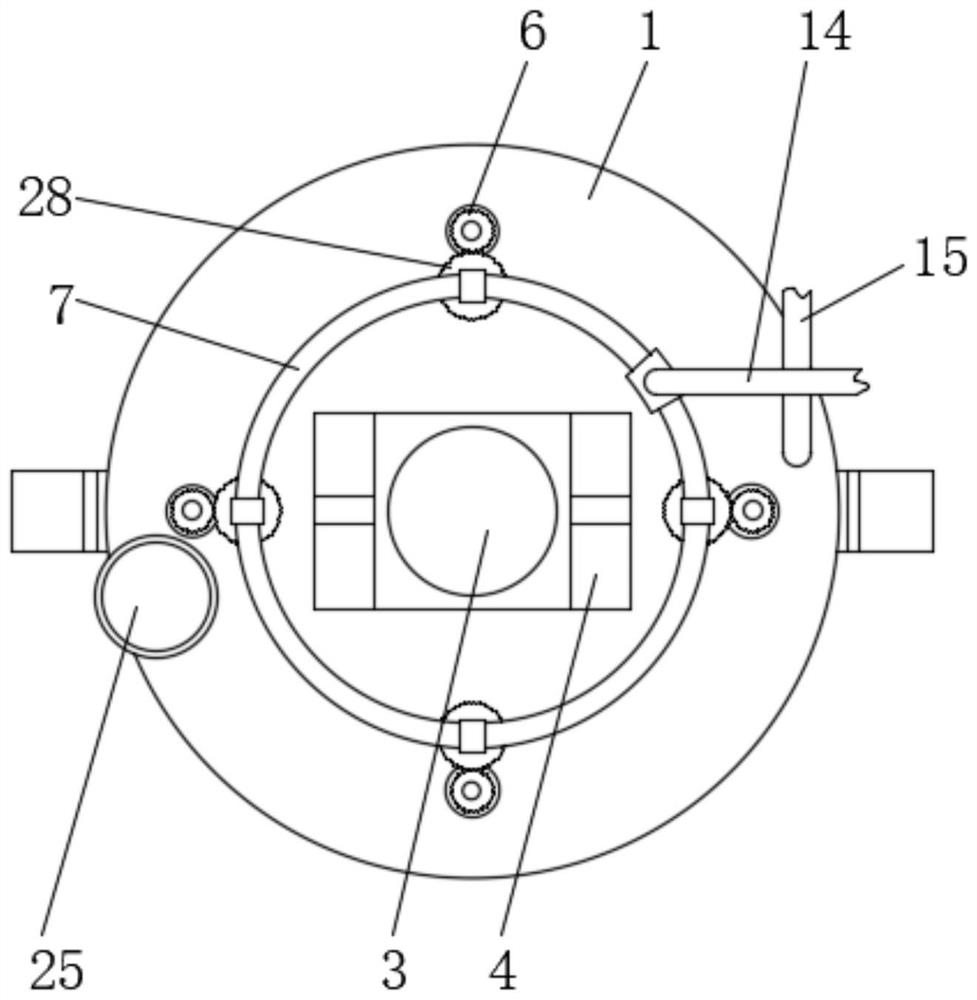

Leaching tank stirring device having defoaming function

InactiveCN102671566APlay the role of defoamingIncrease lateral cutting forceRotary stirring mixersMixer accessoriesPulp and paper industryCutting force

The invention relates to a leaching tank stirring device having a defoaming function. The stirring device comprises a long stirring shaft, a first motor, a bracket and stirring vanes, wherein the first motor and the bracket are arranged at one end of the stirring shaft; the bracket is used for fixing the whole stirring device; the stirring vanes taking the stirring shaft as a rotary shaft are arranged on the other end of the stirring shaft; and a cylindrical supporting shaft fixed on the bracket is sleeved outside the stirring shaft, and the supporting shaft is provided with a flaky defoaming mesh perpendicular to the axis of the supporting shaft. According to the leaching tank, the defoaming mesh is integrated on the stirring shaft of the conventional stirring device, so the foam floating on the surface of mixed liquid can be removed when the stirring vanes rotate or stop rotating. The defoaming mesh has a rotary structure independent of the stirring shaft, and the axial height is adjustable, so the transverse cutting force for foam is increased, the degree of adaptability to the tanks with different heights and the mixed liquid with different liquid levels is improved, and the defoaming effect is strengthened.

Owner:SUZHOU JINXIANG TITANIUM EQUIP

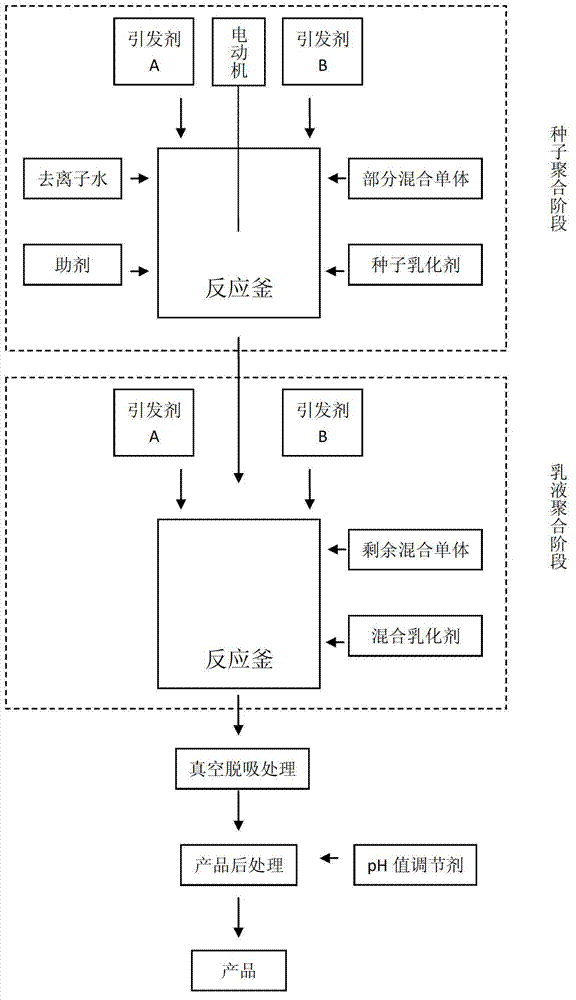

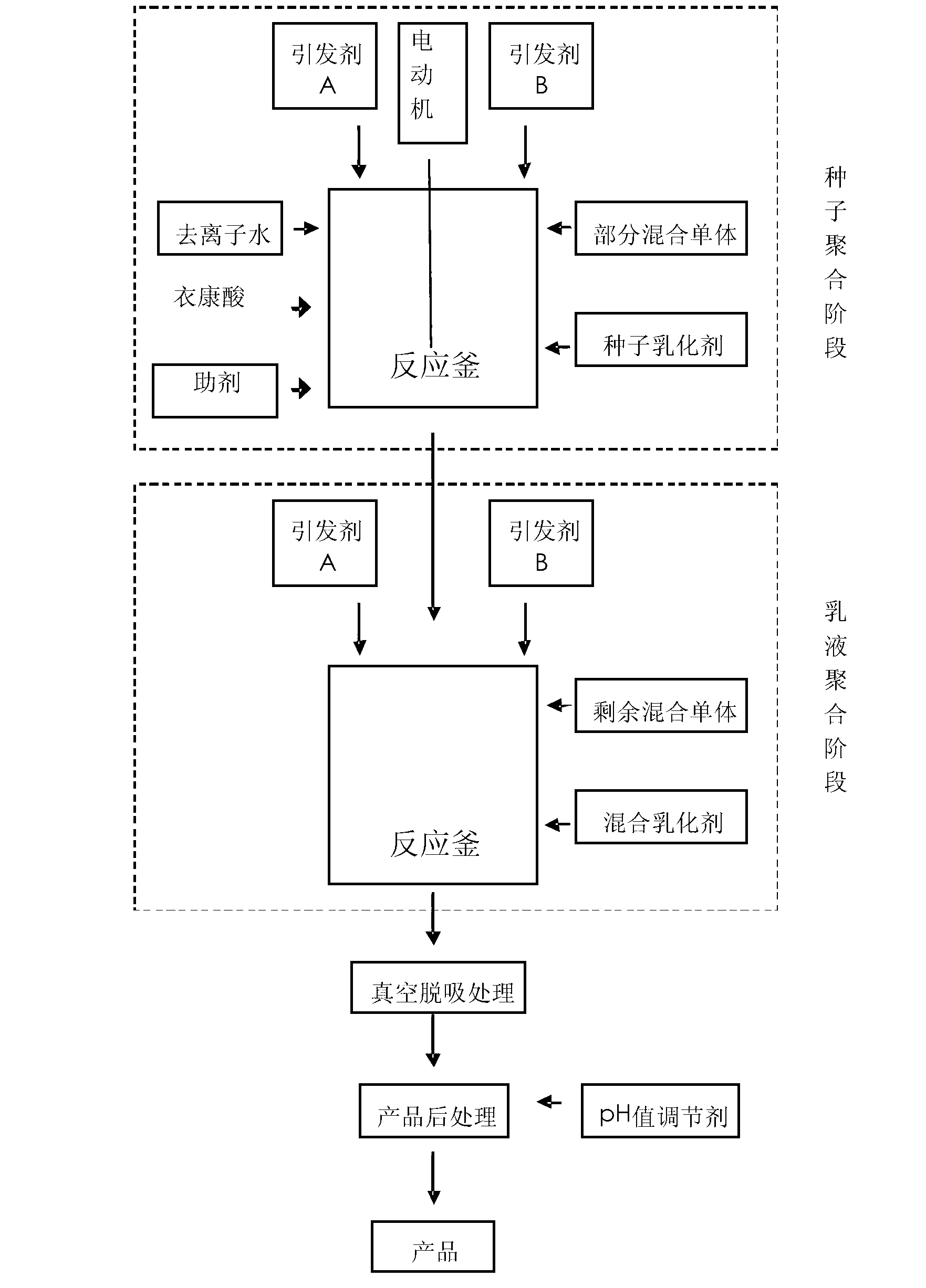

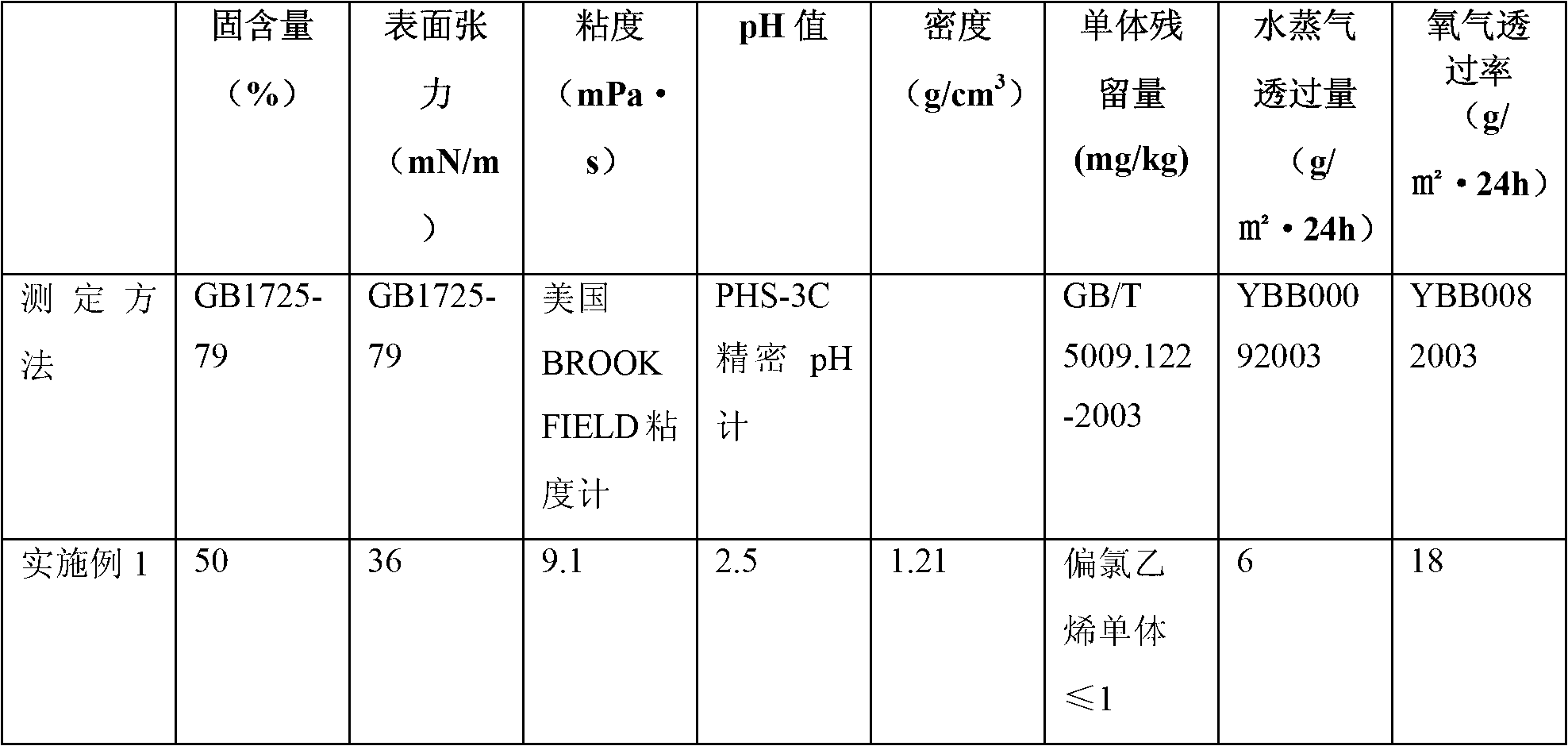

Paper coating water-based emulsion and preparation method and applications thereof

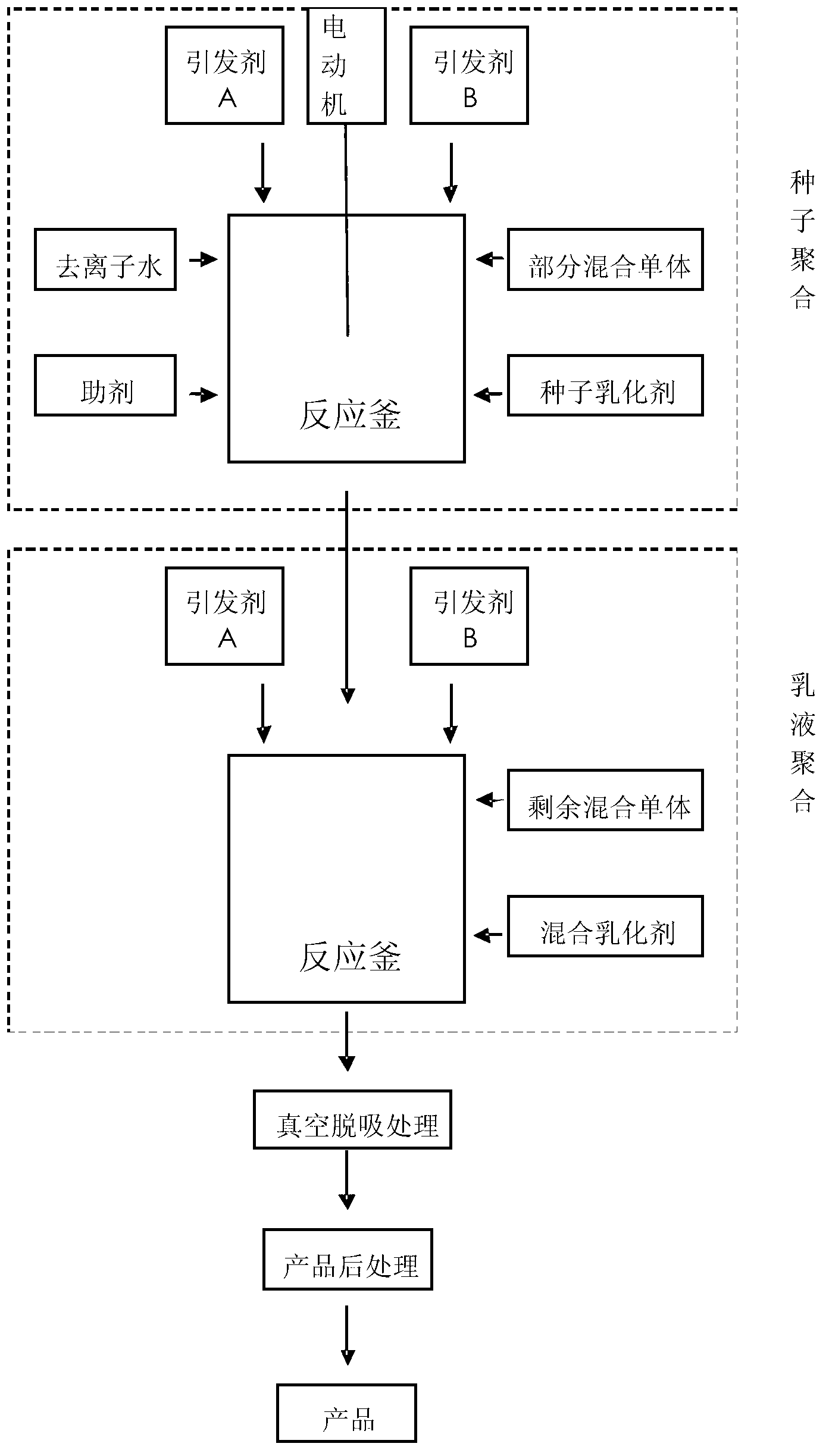

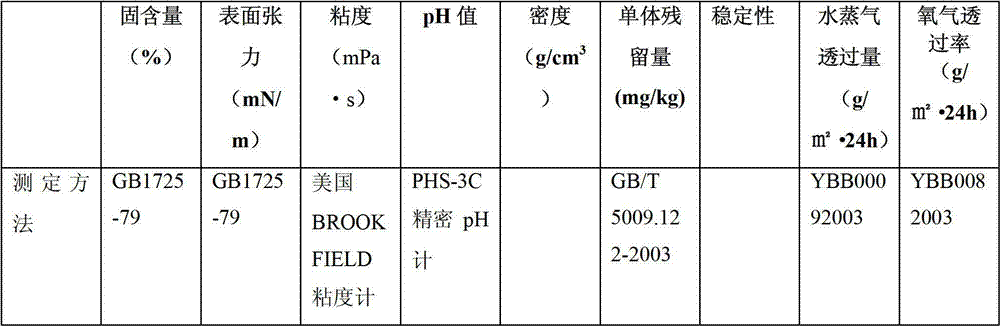

The invention discloses a paper coating water-based emulsion and a preparation method and applications thereof. Aiming at the problem that the barrier property of the current paper coating emulsion is not good, the invention provides the paper coating water-based emulsion. The method comprises the following steps: using a certain amount of vinylidene chloride, acrylonitrile, methacrylate and methacrylic acid as a mixed monomer, selecting a special seed emulsifier and a mixed emulsifier, adopting seed emulsion polymerization, and finally obtaining the paper coating water-based emulsion. The paper coating water-based emulsion has good stability, environmental protection and good barrier property. A vacuum desorption post-processing method is adopted in the later period of emulsion polymerization, so that the monomer residual quantity of the obtained water-based emulsion is low. The prepared coated paper has no foreign smell, cannot pollute food or drugs, and is more beneficial to applications to the package field of food, drugs and the like.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Good water resistance aqueous polyurethane adhesive

InactiveCN105238329AGood weather resistanceImprove mechanical propertiesNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyurethane adhesivePolyvinyl alcohol

The present invention discloses a good water resistance aqueous polyurethane adhesive, wherein the raw materials comprise, by weight, 50-60 parts of a modified polyurethane emulsion, 0.06-1.8 parts of polyvinyl alcohol, 0.01-0.08 part of BYK333, 0.01-0.018 part of an aqueous defoamer, 5.9-12.9 parts of kaolin powder, 0.03-0.57 part of titanium dioxide powder, 0.2-3.9 parts of an aqueous curing agent, 0.1-0.3 part of an antioxidant 1010, 0.5-1 part of sodium dodecyl benzene sulfonate, 0.1-0.2 part of an ultraviolet absorber 531, 0.6-1 part of a wetting agent Wet265, 0.3-0.7 part of 3-aminopropyl triethoxysilane, and 0.2-0.4 part of a polysiloxane macromolecule compound. The good water resistance aqueous polyurethane adhesive of the present invention has characteristics of good water resistance, high mechanical strength, and good adhesion.

Owner:安徽大松树脂有限公司

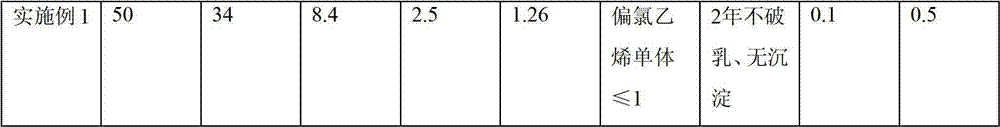

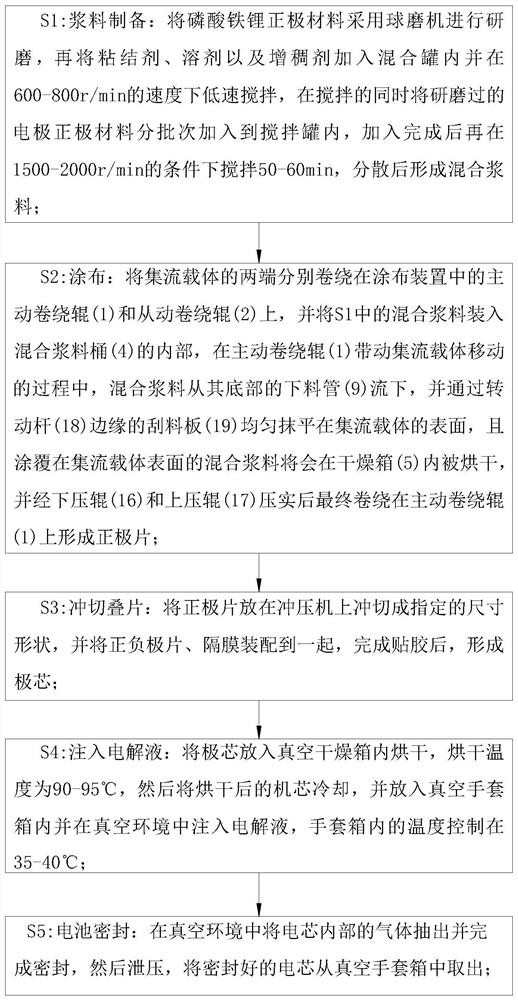

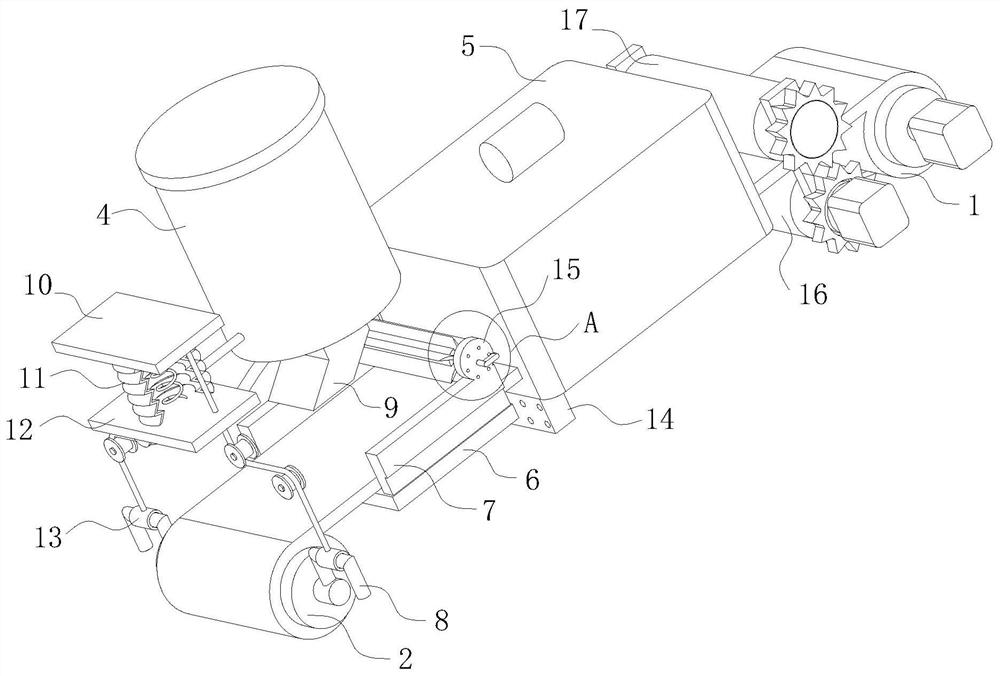

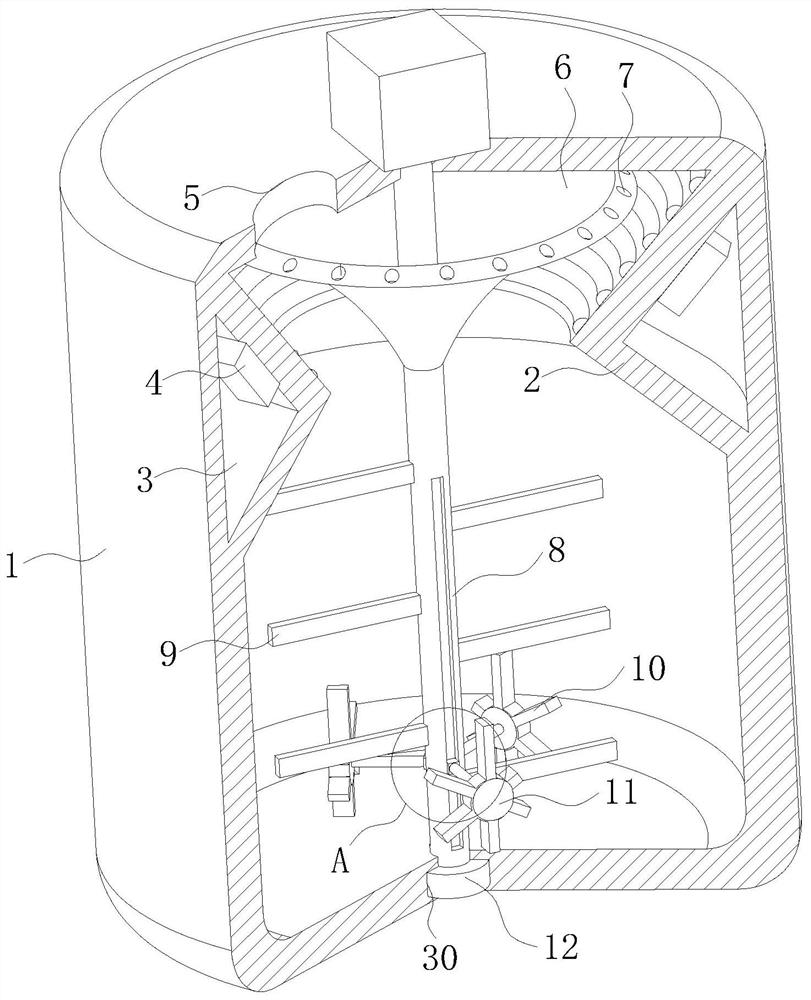

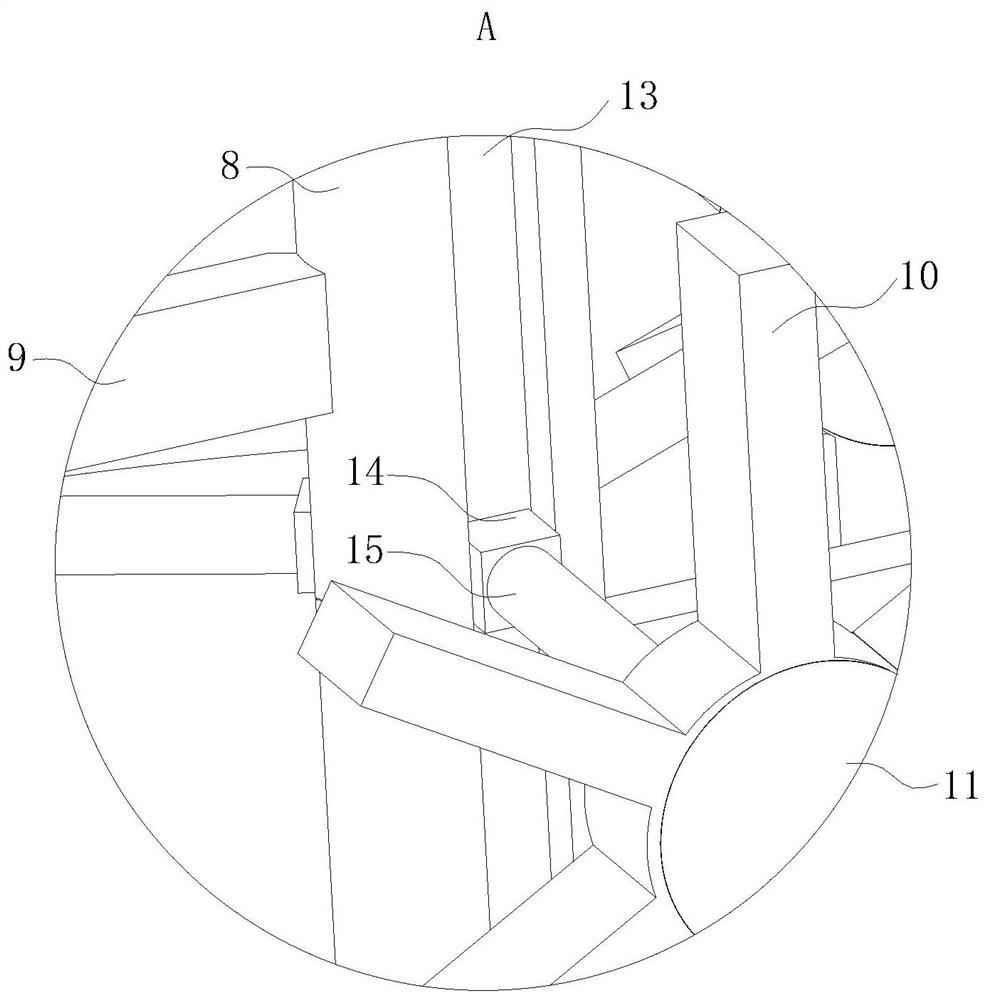

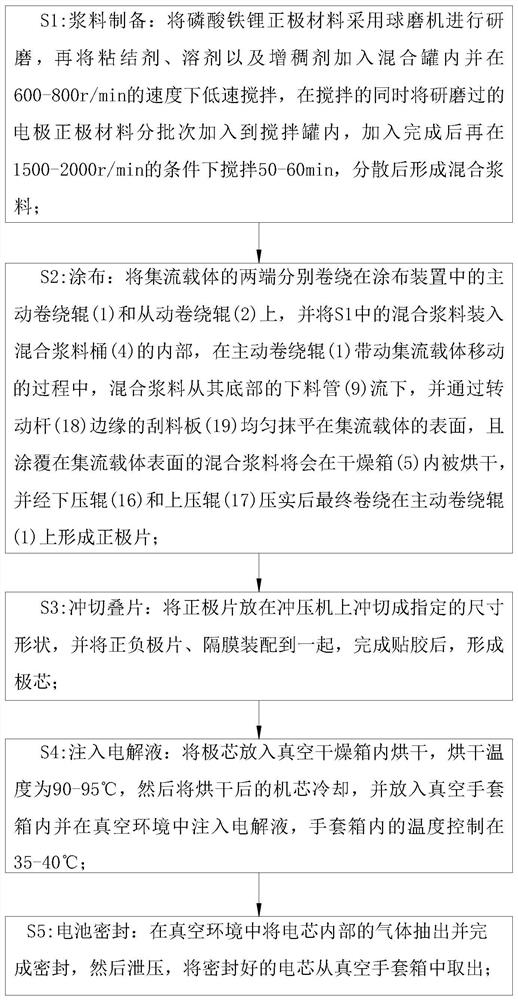

Lithium battery production process

ActiveCN112103465AAdjustable thicknessEliminate Bubble ProblemsFinal product manufacturePretreated surfacesLithium iron phosphatePhysical chemistry

The invention belongs to the technical field of lithium batteries, and particularly relates to a lithium battery production process, which comprises: slurry preparation: grinding a lithium iron phosphate positive electrode material by using a ball mill, adding a solvent and a thickener to a mixing tank, and carrying out low-speed stirring at a speed of 600-800 r / min to obtain a slurry, while stirring, adding the ground electrode positive electrode material into the stirring tank in batches; and stirring the components for 50-60 minutes after the addition is finished, uniformly stirring the solvent and the thickening agent, and adding the powder of the positive electrode material in batches. According to the coating device, bubbles in the mixed slurry can be eliminated, so that the coatingis more uniform and compact, the coating thickness can be adjusted, and the coating device can be used for manufacturing pole pieces with different discharge intensities; meanwhile, the step of extruding the current collection carrier coated with the mixed slurry by using the lower pressing roller and the upper pressing roller is added in the coating device, so that the mixed slurry is more compact, the discharge time of the lithium battery can be further increased and the service life of the lithium battery is prolonged.

Owner:淮北市智俊科技有限公司

Aqueous polyurethane adhesive

InactiveCN105238328ASmall dispersionEvenly dispersedNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPROPYLENE GLYCOL BUTYL ETHERPolyurethane adhesive

The present invention discloses an aqueous polyurethane adhesive, wherein the raw materials comprise, by weight, 80-100 parts of a modified polyurethane emulsion, 1-3 parts of a polyurethane thickener, 0.02-0.13 part of an organosilicon leveling agent, 0.005-0.01 part of an organosilicon efficient anti-foaming agent Tego901W, 0.005-0.02 part of dipropylene glycol butyl ether, 10-20 parts of fumed silica, 0.05-1 part of titanium dioxide powder, 1-5 parts of an aqueous curing agent, 0.2-0.4 part of an antioxidant 264, 0.8-1.2 parts of an emulsifier 6100, 0.2-0.3 part of an ultraviolet absorber RMB, 1-1.4 parts of a wetting agent Wet500, 0.7-1 part of gamma-aminopropyl methyl diethoxy silane, 0.3-0.7 part of a polysiloxane polymer compound, 0.1-0.2 part of methylisothiazolinone, and 0.2-0.3 part of N-octyl-4-isothiazolin-3-one.

Owner:安徽大松树脂有限公司

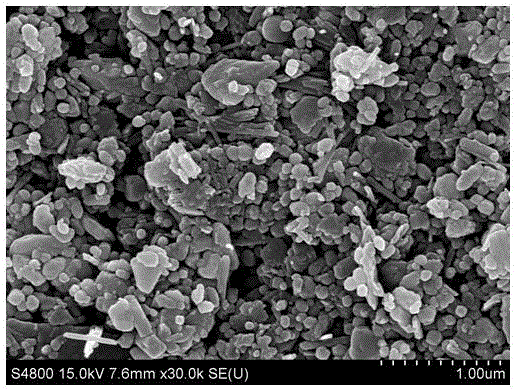

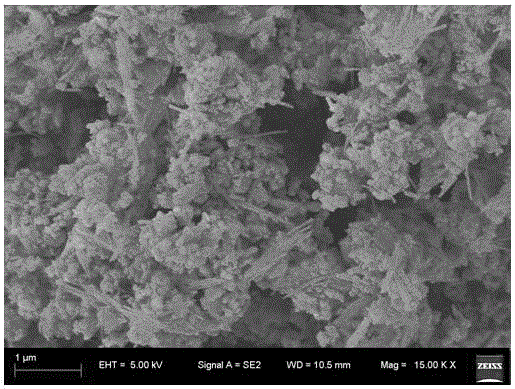

Preparation method for stably suspended and dispersed nano-zinc oxide slurry

ActiveCN106543795AResolve aggregationPrevent subsidenceCosmetic preparationsNon-macromolecular adhesive additivesNano zinc oxideCalcium carbonate

The invention discloses a preparation method for stably suspended and dispersed nano-zinc oxide slurry, and relates to the technical field of semiconductor material production. The method comprises the steps of firstly, adding nano-zinc oxide in a process of preparing calcium carbonate by adopting a gas-solid reaction, and obtaining monodisperse nano-zinc oxide loaded to the surface of calcium carbonate of a submicrometer structure after calcium carbonate is completely generated; and secondly, taking attapulgite clay as anti-settling, thixotropic and thickening agents, and performing sanding to obtain a target product. According to the method, a nano-zinc oxide dispersion modification technology is successfully formed, and the stably suspended and dispersed nano-zinc oxide slurry is further prepared, so that the difficult problem of aggregation of nano-zinc oxide in use is radically solved.

Owner:扬州市维纳复合材料科技有限公司

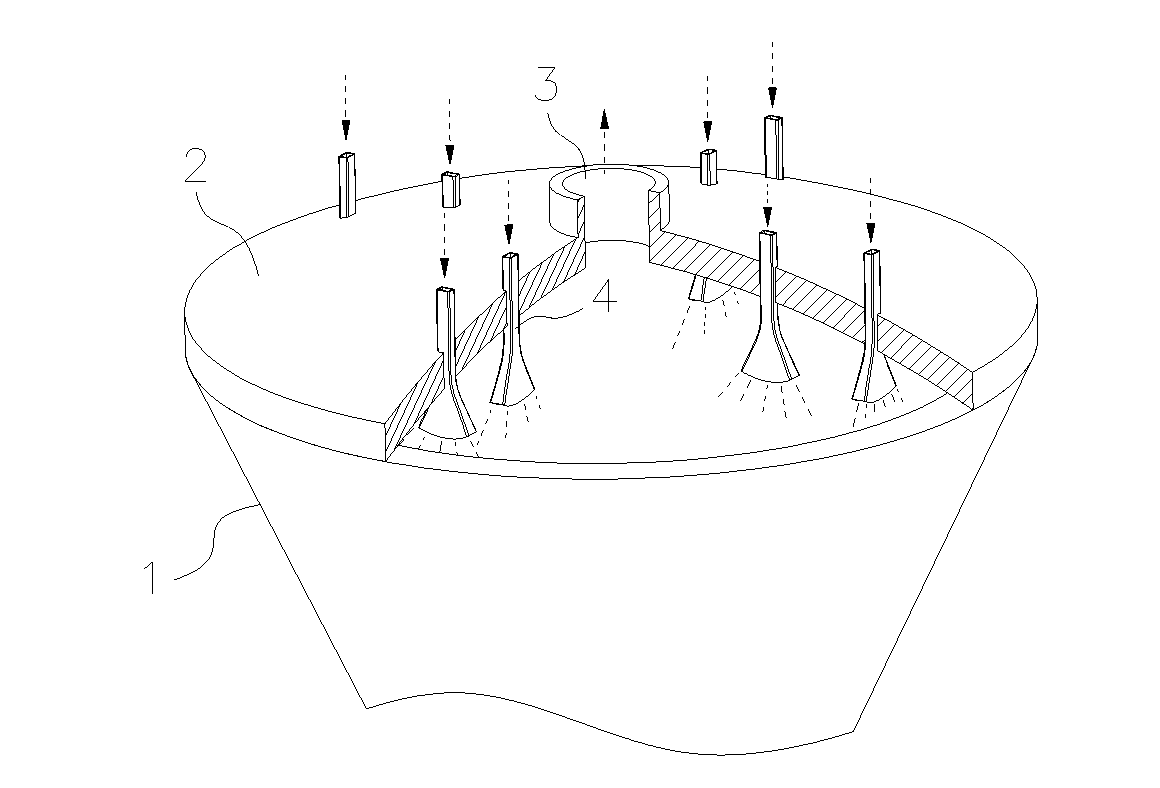

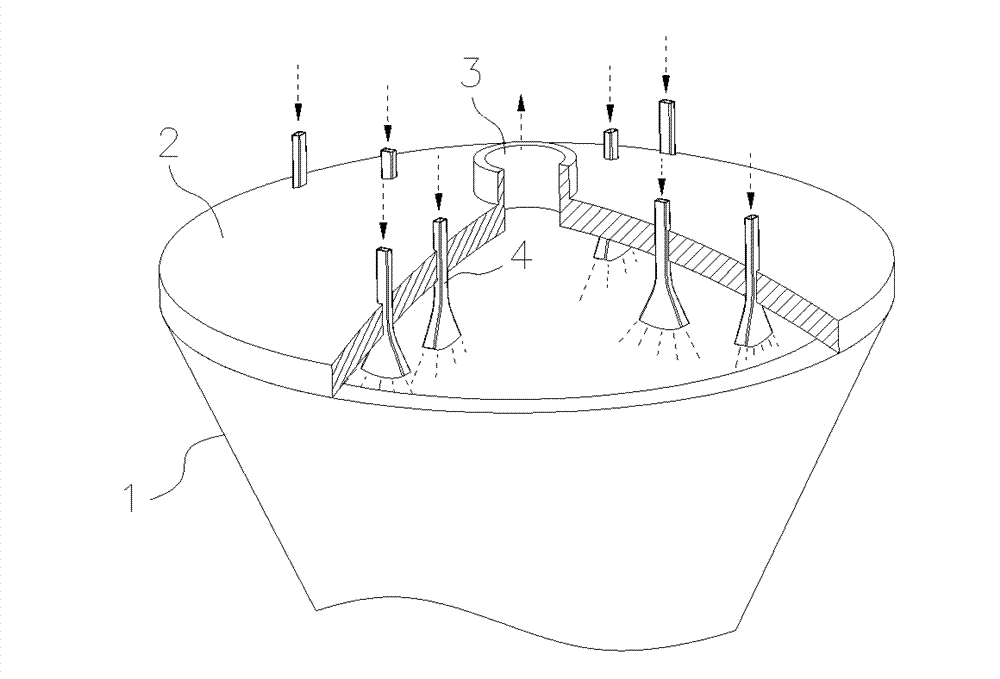

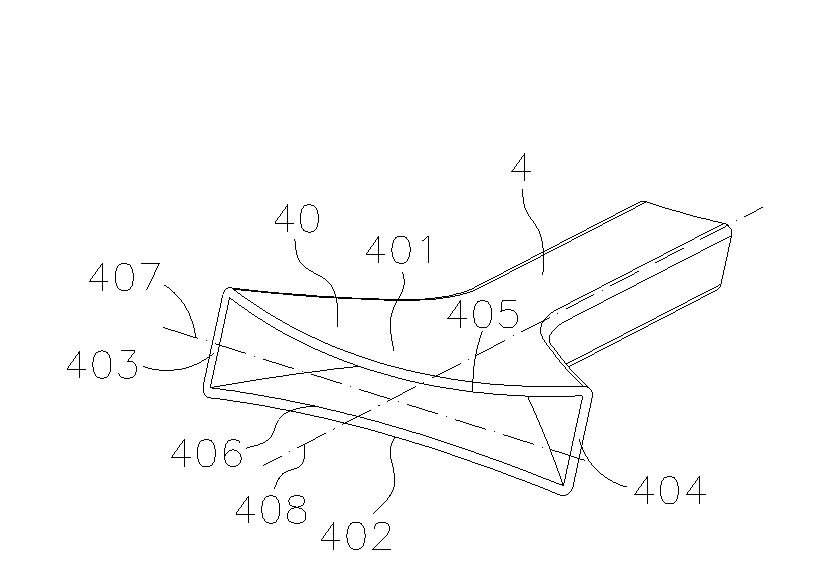

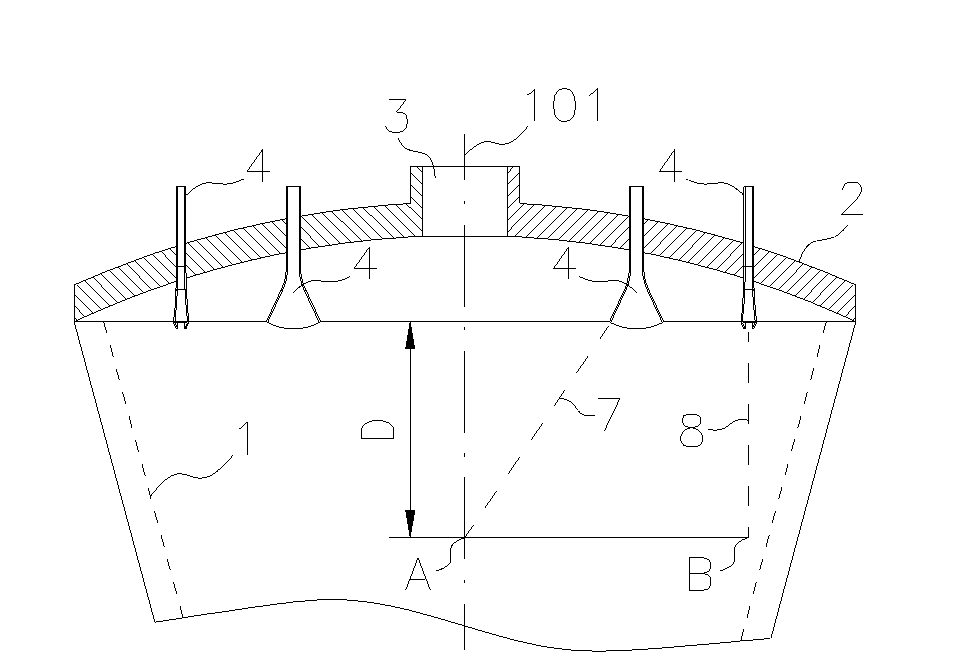

Cover type defoamer and acidolysis process for preparing titanium white powder by sulfuric acid method

The invention discloses a cover type defoamer with a defoaming function. The cover type defoamer comprises a seal cover piece provided with a gas releasing opening and a plurality of compressed gas defoaming spray guns arranged on the seal cover piece, wherein nozzles of the compressed gas defoaming spray guns point to a reaction vessel matched with the seal cover piece. By using the cover type defoamer, an acidolysis process for preparing titanium white powder by an improved sulfuric acid method comprises the following steps of: a, uniformly mixing a titanium raw material and concentrated sulfuric acid in an acidolysis pot and adding starting water to initiate a main reaction; b, starting the compressed gas defoaming spray guns in the cover type defoamer; and c, shutting off the compressed gas defoaming spray guns after the main reaction is finished. In the cover type defoamer, foams in the reaction vessel are broken by the impact effect of compressed gas, and the foams are broken forcibly to release a large quantity of gases, so that the defoamer can be used for restraining the increase of foam volume, has a defoaming effect and is suitable for a plurality of types of acidolysisprocesses.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

Polyvinyl dichloride (PVDC) emulsion for cellophane coating and preparation method thereof and application thereof

ActiveCN103059200AExcellent oxygen barrierImprove water resistancePaper coatingCoatingsMethacrylateEmulsion

The invention discloses a polyvinyl dichloride (PVDC) emulsion for cellophane coating and a preparation method and application of the PVDC emulsion for the cellophane coating. The PVDC emulsion for the cellophane coating aims at solving the problems that existing cellophane is poor in barrier property, incapable of being used for food packaging and the like. The PVDC emulsion for the cellophane coating is obtained by serving a certain amount of vinylidene chloride, acrylonitrile, methacrylate and itaconic acid as a mixed mononer, selecting specific seeded emulsifier and mixed emulsifier, and adopting seeded emulsion polymerization. The PVDC emulsion for the cellophane coating is low in cost and good in barrier property. The coated cellophane is good in oxygen-resisting and waterproof effects and capable of being used for the food packaging.

Owner:海南海达丰实业有限公司

Anti-icing wind power blade and preparation method thereof

InactiveCN109722150AGood weather resistanceImprove hydrophobicityPolyurea/polyurethane coatingsWeather resistanceWind power

The invention relates to an anti-icing wind power blade and a preparation method thereof, wherein the outer surface of the wind power blade is coated with a coating material, and the coating materialcomprises, by weight, 20-30 parts of a resin, 1-2 parts of a dispersant, 10-14 parts of a pigment, 0.01-3 parts of an electric conduction material, 0.2-0.4 part of a defoamer, 0.1-0.2 part of a leveling agent, 1-3 parts of a rheological aid, 3-5 parts of a matting agent, 2-4 parts of an adhesion promoter, 0.01-0.5 part of an initiator, 3-10 parts of butyl acetate, 5-8 parts of propylene glycol methyl ether acetate, 6-10 parts of light calcium carbonate, 0.5-0.9 part of anti-settling fumed silica, and 0.2-0.3 part of xylene. According to the present invention, after the blade is coated with thecoating material, the weather resistance, the hydrophobicity, the impact resistance and the wear resistance of the blade are improved so as to save the maintenance cost and prolong the service life.

Owner:天津华宇天亿新能源科技有限公司

Water-based silver ink and preparation method thereof

The invention discloses water-based silver ink and a preparation method thereof and belongs to the technical field of macromolecular compositions and preparation thereof. The water-based silver ink comprises the following components in parts by mass: 10-30 parts of silver paste, 30-50 parts of a waterborne binder, 0.5-5 parts of a wear-resistant agent, 0.2-2 parts of a wetting agent, 0.2-1 part of a defoaming agent, 10-20 parts of alcohol and 10-20 parts of water. The water-based silver ink selects water as a solvent, no VOC emission is caused in production and usage processes, harmful substance residues on the surface of a printing product are few, an operating environment is safe, the health of production personnel is guaranteed, and the production cost is low; and by adding auxiliaries such as the defoaming agent and the wetting agent in a water-based silver formula, the problems that the water wettability of the silver paste is poor, bloating, precipitating and caking phenomena of silver ink appear and deep printing drying is slow are effectively solved.

Owner:CHANGDE JINPENG PRINTING

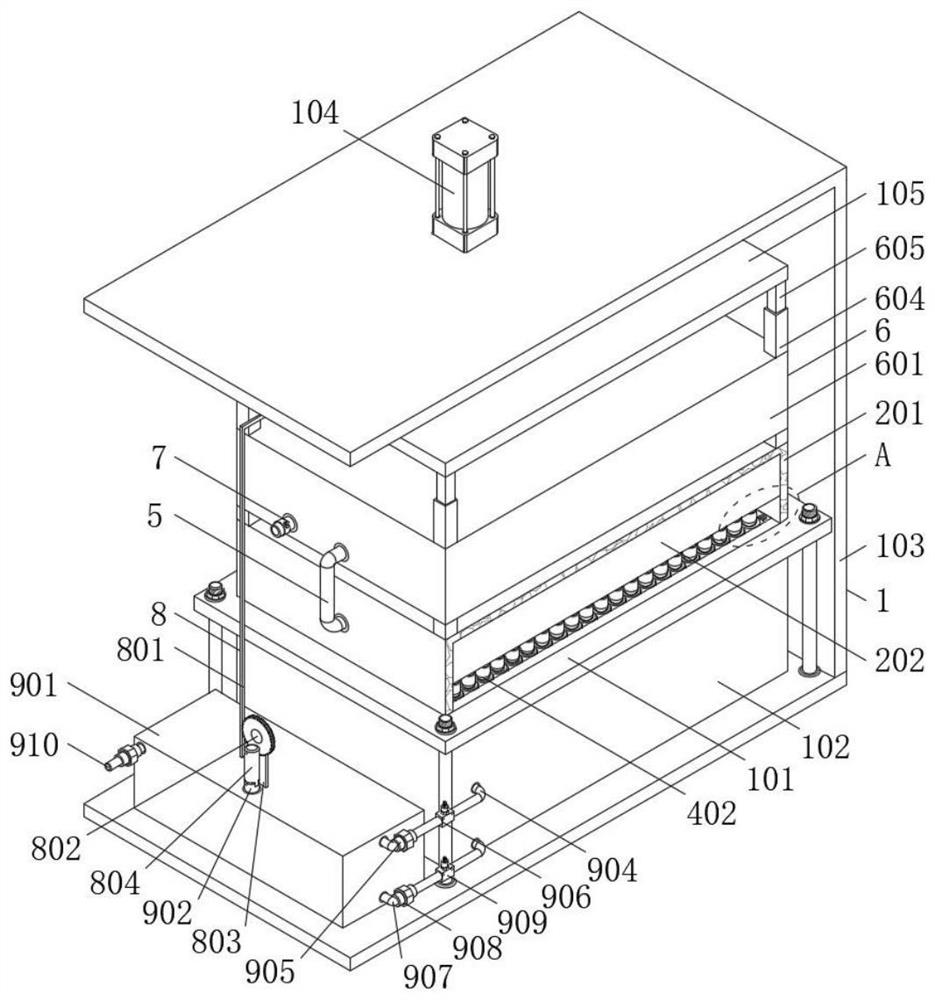

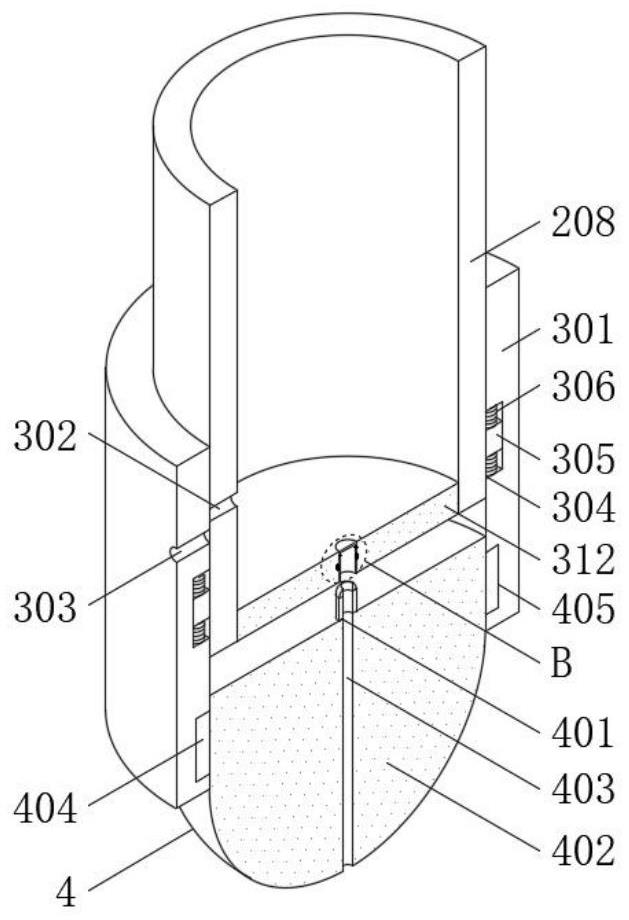

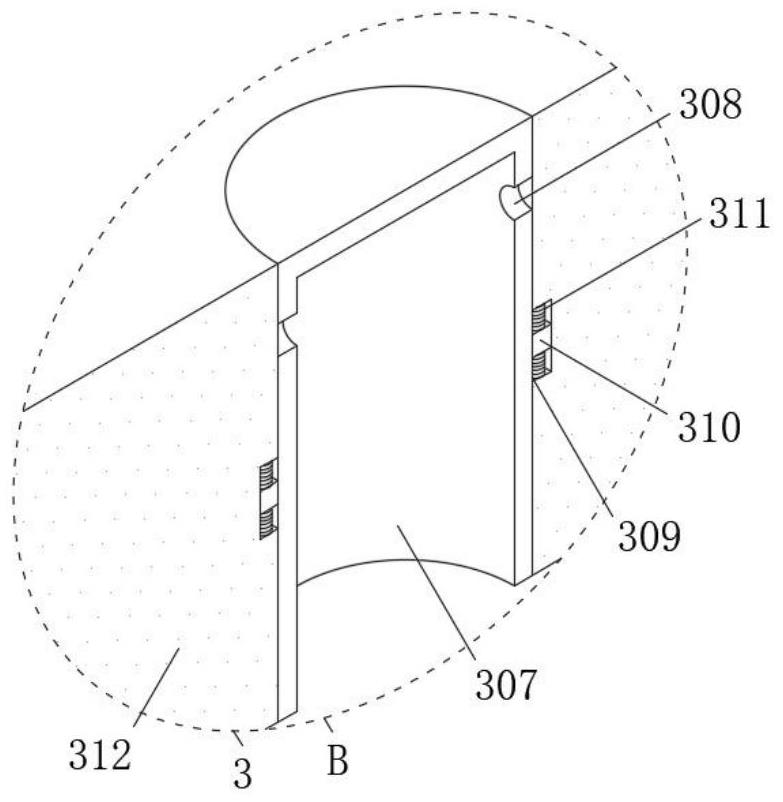

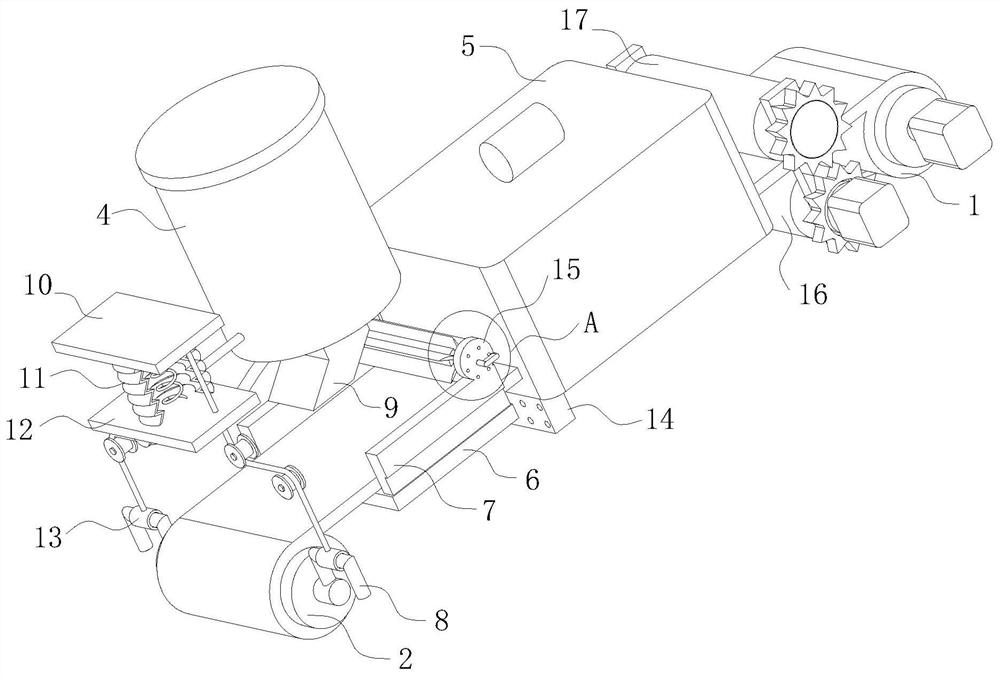

Isobaric liquid injection device of automobile lithium battery liquid injection machine

ActiveCN113991264AImprove efficiencyReduce the number of air bubblesCell component detailsEngineeringElectrical and Electronics engineering

The invention discloses an isobaric liquid injection device of an automobile lithium battery liquid injection machine, and belongs to the technical field of lithium battery production equipment. The isobaric liquid injection device comprises a supporting assembly, a liquid injection assembly is arranged on the inner side of the supporting assembly, and the surface of the liquid injection assembly is sleeved with a first linkage assembly. According to the invention, a second hydraulic cylinder is controlled to operate through a designed trigger assembly and the designed liquid injection assembly, in the working process of the second hydraulic cylinder, the output shaft of the second hydraulic cylinder can drive a first insection panel to transversely move, through the linkage effect between the first insection panel and an outer insection surface, a built-in adapter barrel can drive a movable conical barrel to quickly rotate in the fixed circular barrel, electrolyte entering the fixed circular barrel enters along a drainage pipeline on the tangent plane, gas mixed in the electrolyte can be effectively removed under the action of centrifugal force, the defoaming effect can be achieved at the same time, and the efficiency of injecting electrolyte into the battery shell can be improved.

Owner:深圳市精朗联合科技有限公司

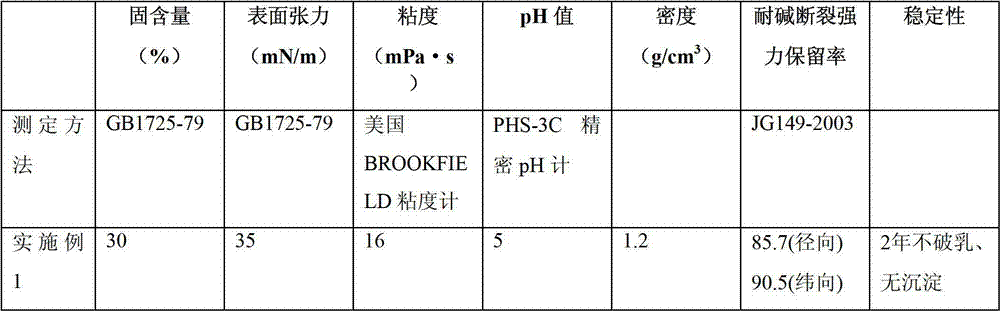

Styrene copolymer emulsion for dip coating of glass fibers and preparation method and application of styrene copolymer emulsion

The invention discloses a styrene copolymer emulsion for dip coating of glass fibers and a preparation method and an application of the styrene copolymer emulsion. In order to solve the problem that the glass fibers subjected to dip coating are low in alkali resistance in the prior art, the styrene copolymer emulsion is prepared by taking a certain quantity of styrene, acrylonitrile and acrylate as a mixed monomer, selecting a specific seed emulsifier and a blended emulsifier, adopting a seed emulsion, and performing polymerization. The styrene copolymer emulsion is good in stability; and the glass fibers treated by using the styrene copolymer emulsion are straight, good in alkali resistance and high in fiber strength.

Owner:HAINAN BNK WATER BASED NEW MATERIAL CO LTD

Computer anti-radiation film material and preparation method thereof

The invention provides a computer anti-radiation film material and a preparation method thereof. The computer anti-radiation film material is prepared from the following components: polycarbonate, modified kaolin, barite powder, cellulose, titanium dioxide, mica powder, zinc ore, calcium carbonate, graphene, composite emulsion, polypropylene glycol, a coalescing agent, an additive, a thickener anddeionized water. The anti-radiation film material prepared by the preparation method provided by the invention not only can greatly improve the anti-radiation effect to reduce harm to human body caused by radiation, but also has the characteristics of waterproofing property, high permeability and relatively good heat dissipation effect; moreover, the anti-radiation film material guarantees normalrunning of a computer, offers safety guarantee for the computer user, and effectively reduces the harm caused by radiation, and thus has relatively high value in use.

Owner:HEFEI XINYADA INTELLIGENT TECH CO LTD

Cover type defoamer and acidolysis process for preparing titanium white powder by sulfuric acid method

The invention discloses a cover type defoamer with a defoaming function. The cover type defoamer comprises a seal cover piece provided with a gas releasing opening and a plurality of compressed gas defoaming spray guns arranged on the seal cover piece, wherein nozzles of the compressed gas defoaming spray guns point to a reaction vessel matched with the seal cover piece. By using the cover type defoamer, an acidolysis process for preparing titanium white powder by an improved sulfuric acid method comprises the following steps of: a, uniformly mixing a titanium raw material and concentrated sulfuric acid in an acidolysis pot and adding starting water to initiate a main reaction; b, starting the compressed gas defoaming spray guns in the cover type defoamer; and c, shutting off the compressed gas defoaming spray guns after the main reaction is finished. In the cover type defoamer, foams in the reaction vessel are broken by the impact effect of compressed gas, and the foams are broken forcibly to release a large quantity of gases, so that the defoamer can be used for restraining the increase of foam volume, has a defoaming effect and is suitable for a plurality of types of acidolysisprocesses.

Owner:PANGANG GROUP VANADIUM TITANIUM & RESOURCES +1

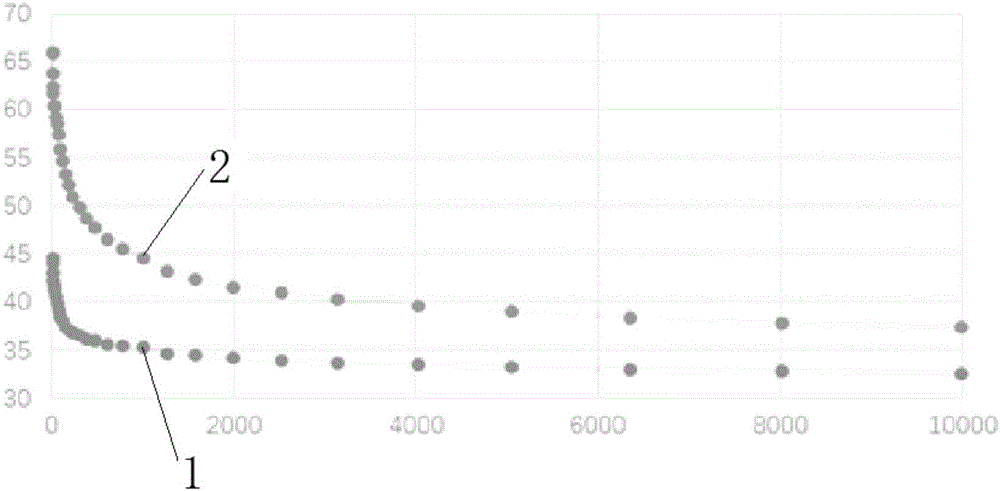

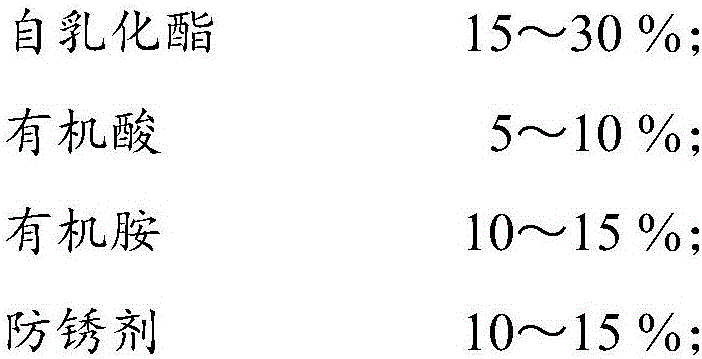

High-detergency low-foam semi-synthesis grinding fluid and preparation method thereof

ActiveCN106635357AMoisturizes and wraps quickly and effectivelyImprove detergencyLubricant compositionOrganic acidMetallurgy

The invention discloses a high-detergency low-foam semi-synthesis grinding fluid. The high-detergency low-foam semi-synthesis grinding fluid comprises the following components in percentage by weight: 15 to 30 percent of self-emulsifying ester, 5 to 10 percent of organic acid, 10 to 15 percent of organic amine, 10 to 15 percent of an antirust agent, 1 to 2 percent of an emulsifying agent, 0.5 to 1 percent of a surfactant, 2 to 5 percent of a coupling agent, 1 to 2 percent of bactericide and the balance of water. The high-detergency low-foam semi-synthesis grinding fluid provided by the invention has excellent detergency performance and excellent low-foam performance, does not use raw materials such as sodium nitrite, nonyl phenol and boric acid harmful to the environment any more, and enables a product to be environmentally-friendly. The invention also discloses a preparation method of the high-detergency low-foam semi-synthesis grinding fluid.

Owner:QUAKER CHEM CHINA

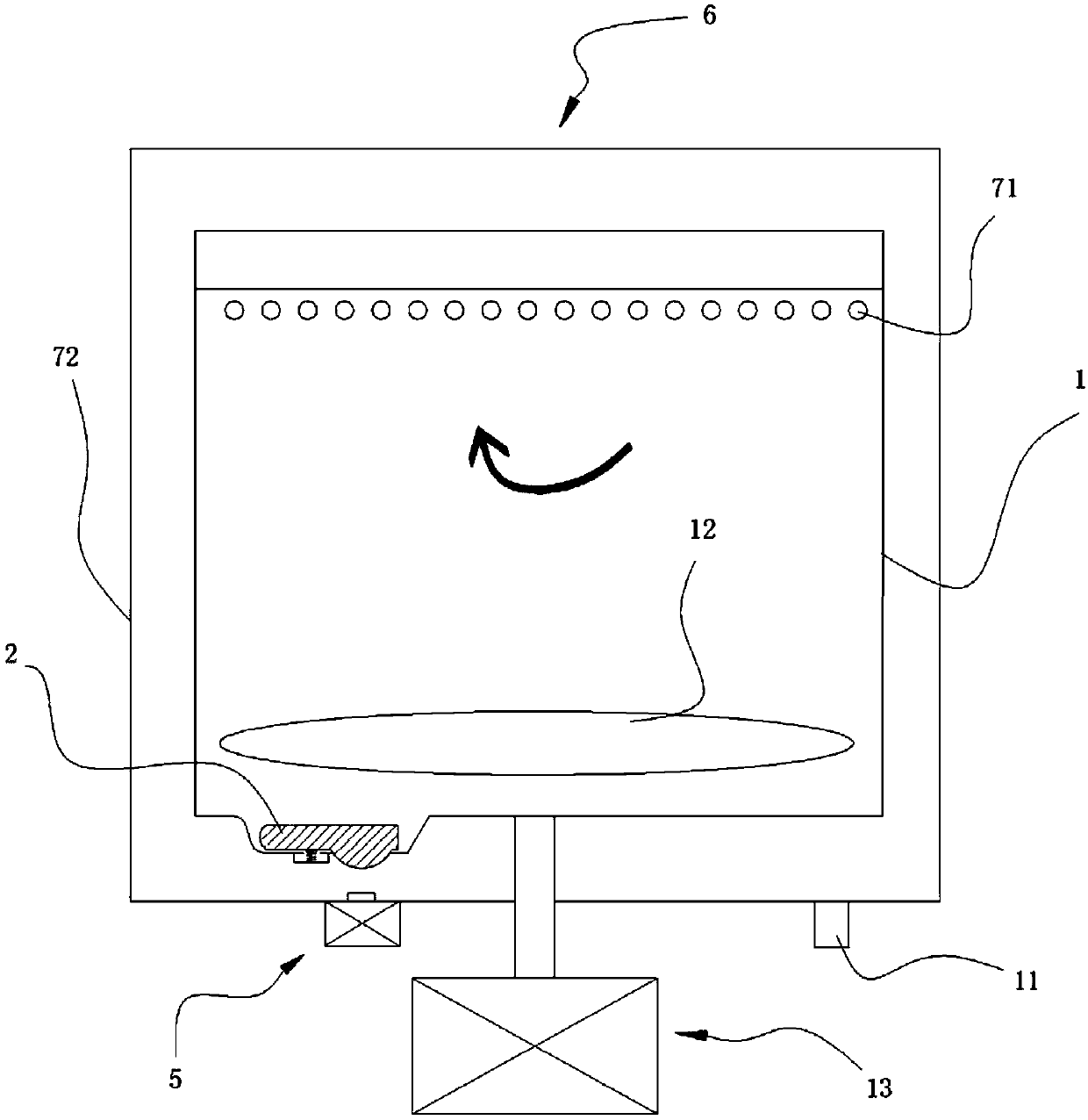

Clothing treatment equipment

PendingCN110409111ASmall sizeEasy dischargeOther washing machinesWashing machine with receptaclesPulp and paper industryClosed state

The invention discloses clothing treatment equipment. The clothing treatment equipment comprises a rotating barrel, a drainage hole and a plugging mechanism, wherein the rotating barrel can rotate inthe axial direction of the equipment, the drainage hole is formed in the lowest position of the bottom of the rotating barrel and the plugging mechanism is arranged at the lowest position to open or close the drainage hole, and the plugging mechanism covers the drainage hole and can rotate along with the rotating barrel when in a closed state. According to the clothing treatment equipment, a structure equivalent to an outer barrel is omitted, all washing water is contained in the rotating barrel, and the consumption of washing water is reduced. In addition, the problem of how to discharge water from the rotating barrel in the washing / dewatering process is effectively solved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD

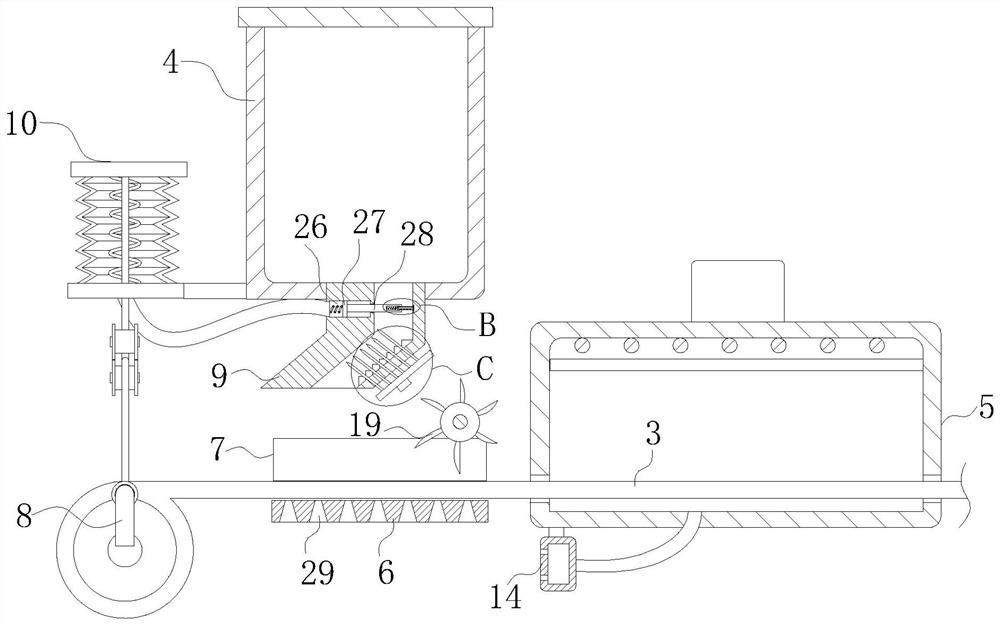

Soybean milk preparation method capable of effectively controlling false boiling of soybean milk machine

The invention relates to a soybean milk preparation method capable of effectively controlling false boiling of a soybean milk machine. The soybean milk machine comprises a cup body, a smashing device,a heating device and an overflow prevention electrode, the smashing device is arranged in the cup body, the heating device heats the cup body, the method comprises (a) smashing stages: including a primary smashing stage and a secondary fine smashing stage, the primary smashing stage is the stage where water and materials are subjected to primary smashing, the secondary fine smashing stage is thestage where a milk liquid obtained after primary smashing is subjected to fine smashing again, a false boiling identification step is arranged between the primary smashing stage and the secondary finesmashing stage, and the false boiling identification step is the stage where the milk liquid obtained after primary smashing is heated to touch the overflow prevention electrode, and then the secondary fine smashing stage is started again. Compared with the prior art, the nutrients can be well released and the flavor can be formed, false boiling can be effectively controlled, and the smashing fineness is high.

Owner:JOYOUNG CO LTD

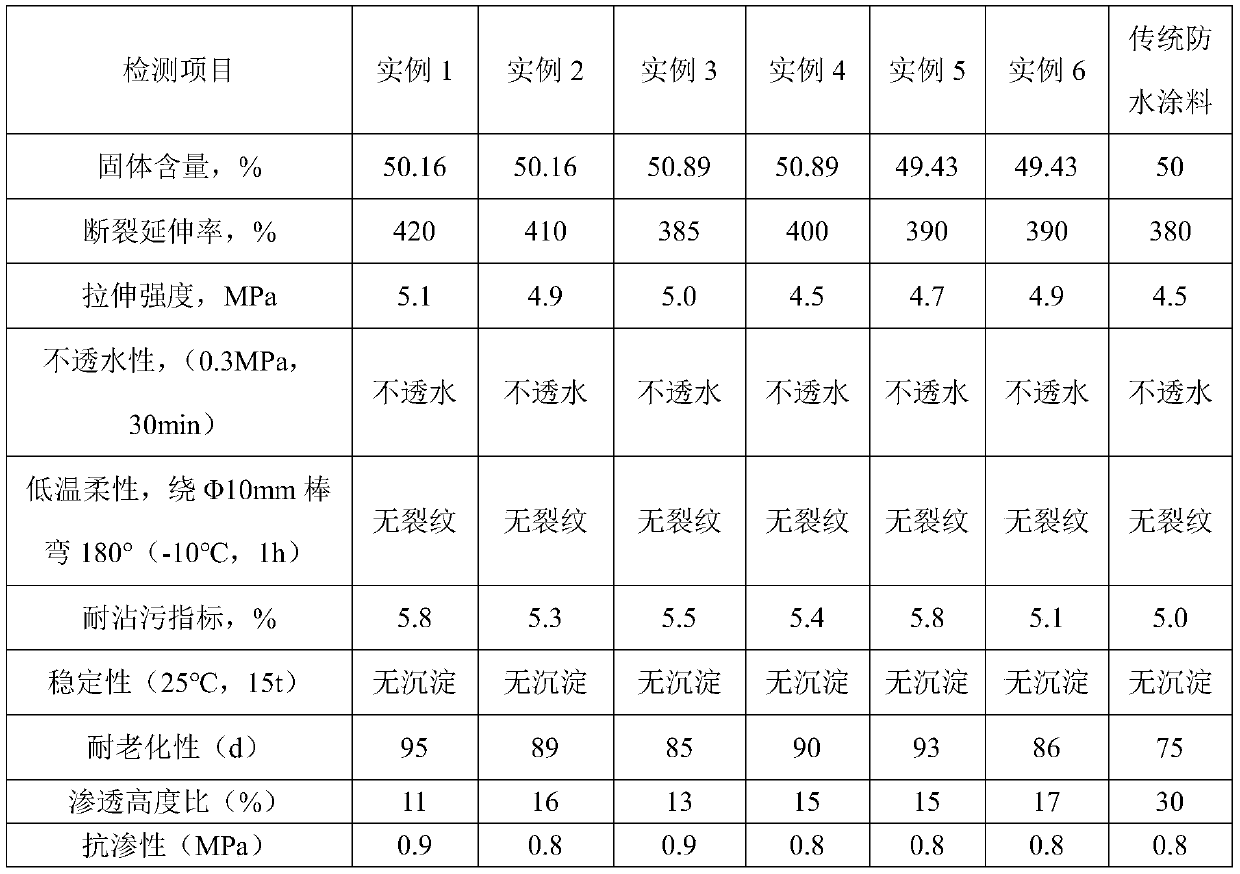

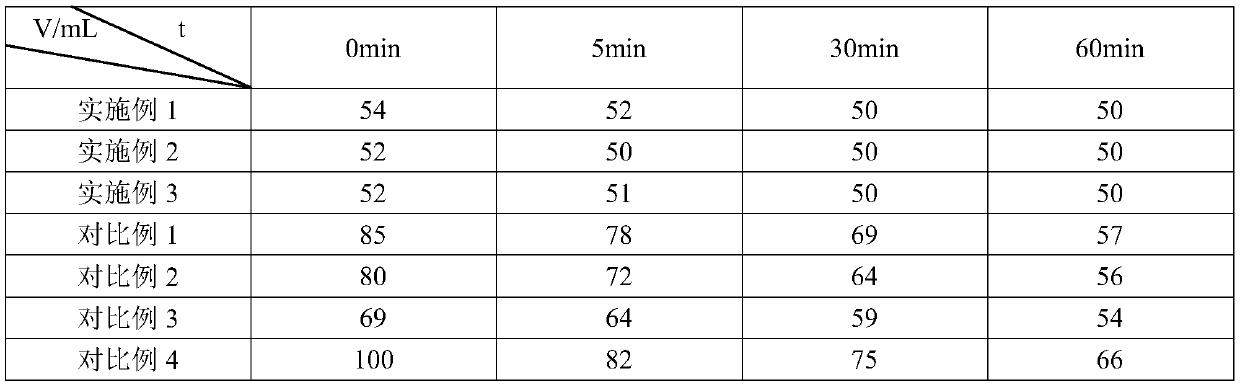

Preparation method of super-concentrated carboxyl-based ester-based emulsion polymer

The invention discloses a preparation method of a super-concentrated carboxyl-based ester-based polymer. The super-concentrated carboxyl-based ester-based polymer is prepared from the raw materials inparts by mass: 1.2-2.7 parts of hydrophilic small monomer for emulsification, 3.3-5.6 parts of hydrophobic small monomer for emulsification, 16-37 parts of carboxyl small monomer, 0.05-0.21 parts ofemulsion initiator, 2.1-5.2 parts of initiator a, 3.2-6.5 parts of initiator b, 370-440 parts of small ester-based monomers, 3.7-8.6 parts of a cross-linking agent, 3.5-7.7 parts of flexible small monomers, 19-44 parts of polyether, 0.2-0.8 part of oxidized graphene, 0.10-0.29 part of a chain transfer agent, 5-10 parts of a neutralizing agent, 5-10 parts of a pH regulator, 2.0-5.0 parts of co-emulsifier, 0.4-1.0 part of liquid film enhancer and the balance of water, the total raw materials is 1,000 parts, and the solid content is 50%. The hydrophobic monomers are adopted to prepare the polymeremulsion with excellent water resisting property. The emulsifier is self-made super-concentrated emulsifier, the generation of bubbles during the reaction is reduced, and the initiators with different initiation efficiency are adopted to stabilize the reaction rate. The polyether is added in the preparation method, and the polymer emulsion is enabled to have better connection property, and further has a good repairing effect as a waterproof coating.

Owner:HUBEI UNIV OF TECH

A kind of aqueous silver ink and preparation method thereof

The invention discloses a water-based silver ink and a preparation method thereof, belonging to the technical field of polymer composition and its preparation. The water-based silver ink includes the following components in parts by mass: 10-30 parts of silver paste, 30-50 parts of water-based binder, 0.5-5 parts of anti-wear agent, 0.2-2 parts of wetting agent, defoamer 0.2-1 part, 10-20 parts alcohol, 10-20 parts water. The water-based silver ink uses water as a solvent, there is no VOC emission during production and use, there are few harmful substances on the surface of the printed matter, the operating environment is safe, the health of production personnel is guaranteed, and the production cost is low; and through the water-based silver formula Adding antifoaming agent, wetting agent and anti-wear agent and other additives, effectively solve the problems of poor water wettability of silver paste, silver ink swelling, precipitation and agglomeration, and slow drying of deep plate printing.

Owner:CHANGDE JINPENG PRINTING

Wire drawing process of automobile mark

ActiveCN110756996AGood dispersionEasy to spreadOrganic detergent compounding agentsSurface-active detergent compositionsPhenyl EthersTriethoxysilane

The invention relates to the technical field of metal processing processes, and discloses a wire drawing process of an automobile mark. The wire drawing process comprises the following steps of S1, the wire drawing procedure and S2 the PVD surface treatment procedure. S2 further comprises the following steps of PVD pretreatment, wherein the automobile mark is cleaned through a cleaning agent, andtime ranges from 15 min to 25 min; secondly, baking, wherein the automobile mark is baked for 10-15 min at the vacuum furnace temperature ranging from 80 DEG C to 90 DEG C; thirdly, hanging up; fourthly, coating; and fifthly, hanging down. The cleaning agent in the first step comprises, by weight, 70-80 parts of polyethylene glycol octylphenol ether and a modifier. The modifier comprises 10-15 parts of methyl triethoxysilane. The wire drawing process has the following advantages and effects that oil dirt can be separated from the metal surface by means of polyethylene glycol octylphenol ether;and methyl triethoxysilane is grafted to polyethylene glycol octylphenol ether, the molecular weight of hydrophilic groups is increased, modified polyethylene glycol octylphenol ether can enter a liquid film more easily, and bubbles can be diffused more easily so as to be permeated and broken.

Owner:NINGBO SWELL IND CO LTD

Oil-immersed distribution transformer convenient for oil injection

InactiveCN113571301AFast flowNot easy to affect normal useTransformers/reacts mounting/support/suspensionTransformers/inductances coolingFiberThermodynamics

The invention discloses an oil-immersed distribution transformer convenient for oil injection, and belongs to the field of oil-immersed transformers. According to the scheme of the oil-immersed distribution transformer convenient for oil injection, in the oil injection process, transformer oil enters a transition chamber through an exchange hole and an elastic fiber cluster, the communicated compartments formed by a straight part and a three-dimensional spiral part in the elastic fiber cluster can effectively buffer the transformer oil, the situation that the flowing speed of the transformer oil is too high is avoided, bubbles are not prone to being formed, meanwhile, the bubbles existing in the transformer can be cut and broken through the straight part, the three-dimensional spiral part and a prefabricated groove, and the bubble removing effect is achieved. In the process of replacing the transformer oil of the oil-immersed transformer, bubbles are not prone to being generated, normal work of the oil-immersed transformer is not prone to being affected, damage caused by overheating of the oil-immersed transformer is not prone to being caused, breakdown of the transformer oil is not prone to being caused, and normal use of the oil-immersed transformer is not prone to being affected.

Owner:江苏泰升电器有限公司

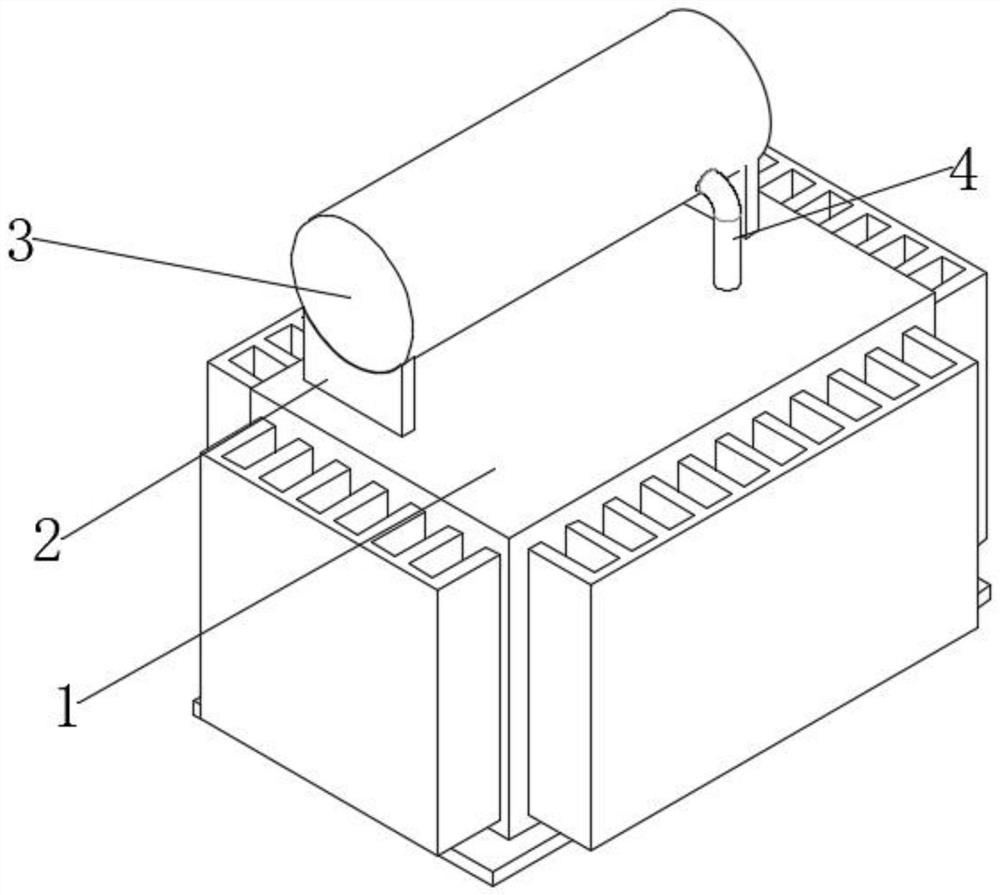

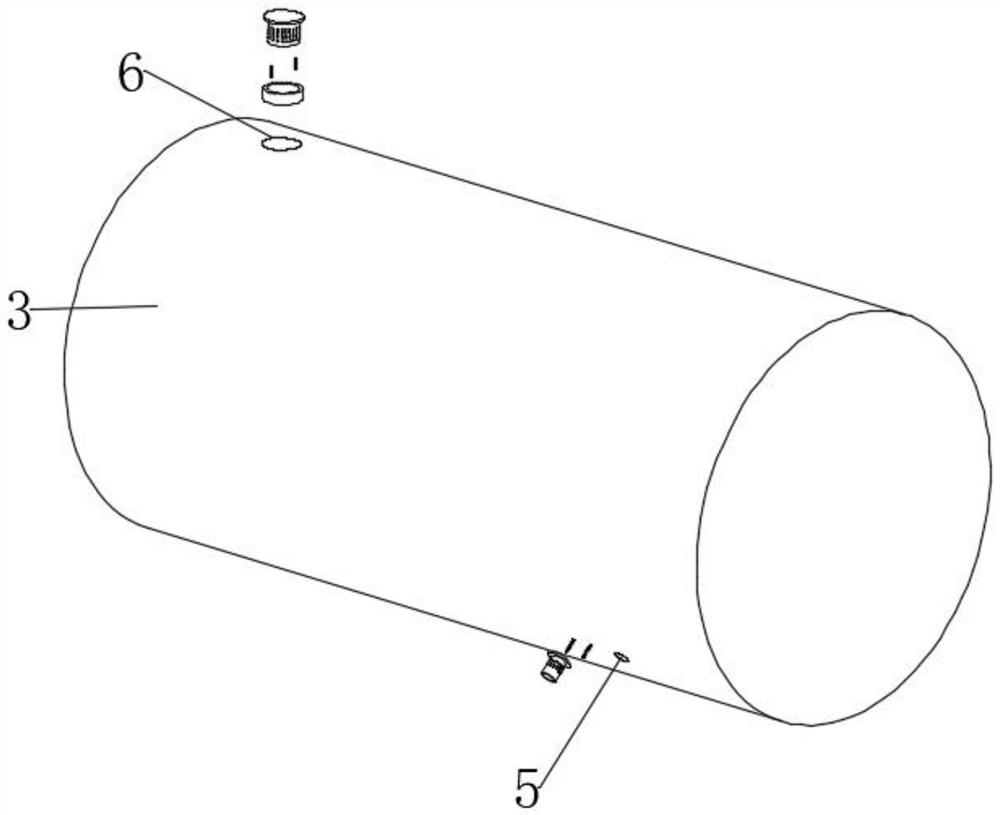

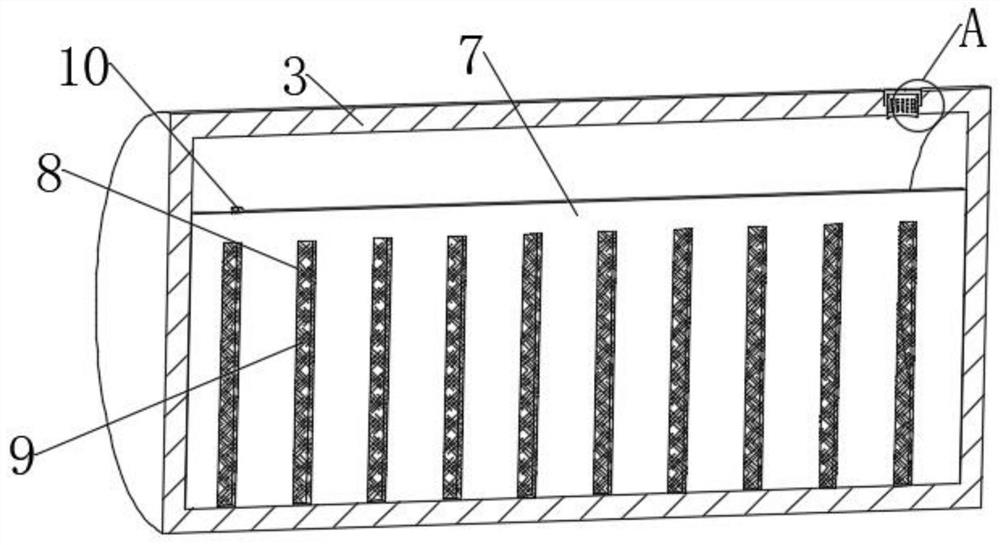

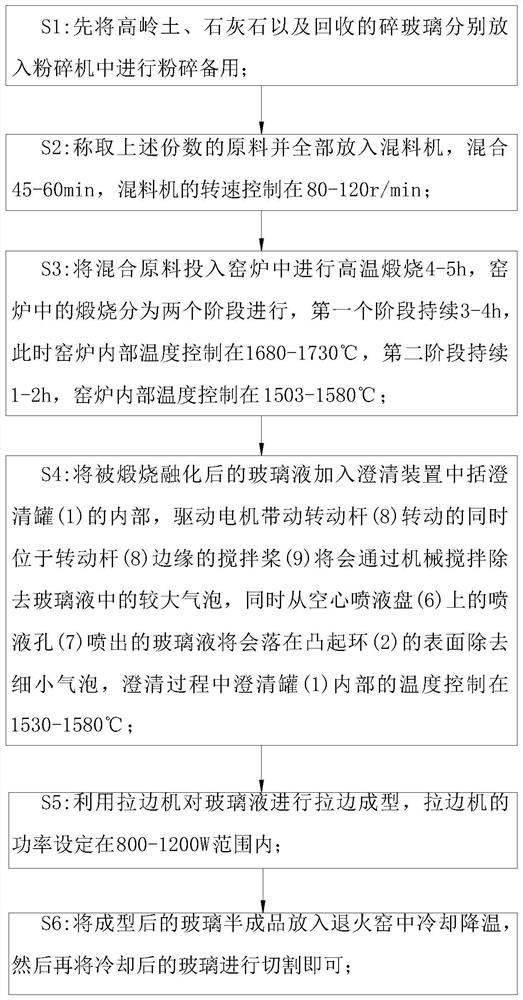

Tempered glass and manufacturing method thereof

ActiveCN112897880AImprove flexural strengthImprove visibilityGlass furnace apparatusFoam dispersion/preventionBreaking strengthKaolin clay

The invention belongs to the technical field of tempered glass production, and particularly relates to tempered glass and a manufacturing method of the tempered glass. The tempered glass is prepared from the following raw materials in parts by weight: 25-40 parts of silicon dioxide, 10-16 parts of limestone, 10-14 parts of kaolin, 14-23 parts of mirabilite, 5-10 parts of sodium carbonate, 5-11 parts of recycled cullet, 4-7 parts of aluminum powder, 0.5-1 part of antimony trioxide and 0.2-0.3 part of ammonium nitrate. According to the invention, the clarifying device is arranged and can play a role in defoaming the interior of molten glass, so that bubbles in a glass finished product can be reduced, the breaking strength of the glass can be greatly improved, and meanwhile, the visibility of the glass is higher and the glass is more attractive; and during actual work, molten glass sprayed on the upper surface of a convex ring can flow downwards and be paved along the upper surface of the convex ring, and a vibration exciter positioned in the annular cavity can enable the surface of the convex ring to vibrate at the moment, so that tiny bubbles in the molten glass paved on the surface of the convex ring are removed through vibration, and the defoaming effect is further improved.

Owner:TAICANG CITY GUANGMING GLASS PRODS

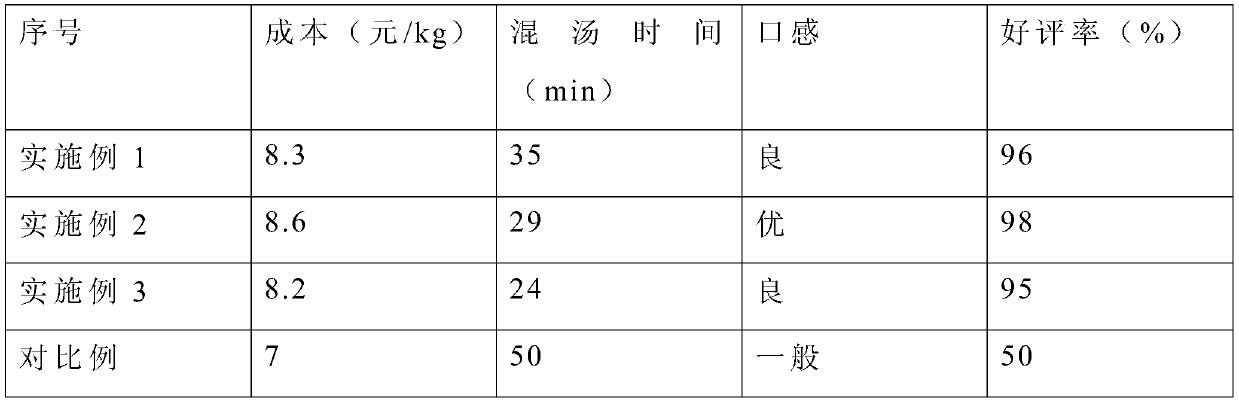

Preparation method of pea vermicelli with short soup mixing time

InactiveCN110833176AFull of nutritionGreat tasteSugar food ingredientsFood ingredient as anti-foaming agentPhysical chemistryProcess engineering

A preparation method of pea vermicelli with short soup mixing time comprises the following steps: cleaning and soaking; grinding: grinding peas subjected to cleaning and soaking to fine powder with fineness of 20-40 meshes; precipitation: grinding the pea fine powder obtained in the grinding step according to the weight ratio of 1: 2-3.5 into clear water to obtain pea milk, filtering the pea milkto remove large particles, leaving the filtrate standstill for a certain time, and taking out bean powder precipitated from the lower layer; drying: placing the pea powder obtained in the precipitation step in a well ventilated place for airing to obtain pea powder with water content of 2%-3%; powder preparation: adding 35-45 ml of water into each jin of pea powder, uniformly stirring to obtain the pea milk, and then placing the pea milk in a powder press to obtain vermicelli; and airing: placing the vermicelli obtained in the powder preparation step in water at the temperature of 8-12 DEG C for cleaning, and then placing the vermicelli in a well ventilated place for airing to obtain the pea vermicelli with the water content of 1.5%-2%.

Owner:湖南城头山丝念食品股份有限公司

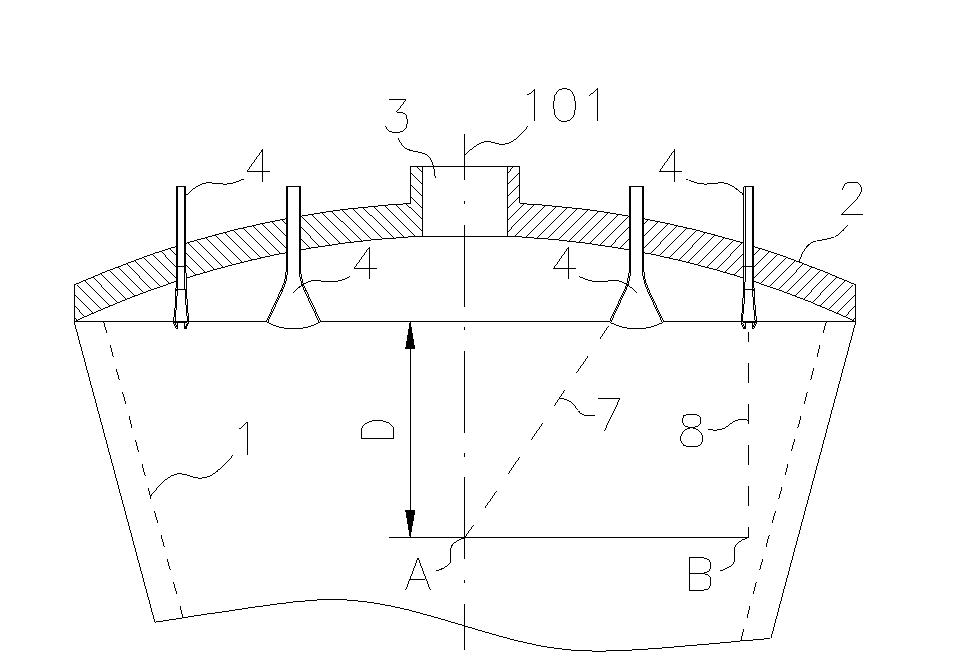

A kind of lithium battery production process

ActiveCN112103465BQuality improvementPlay the role of defoamingFinal product manufactureSecondary cellsLithium iron phosphatePhysical chemistry

The invention belongs to the technical field of lithium batteries, specifically a lithium battery production process, comprising the following steps: slurry preparation: grinding lithium iron phosphate positive electrode materials with a ball mill, adding solvent and thickener into a mixing tank and Stir at a low speed of 600-800r / min, while stirring, add the ground electrode positive material into the stirring tank in batches; after the addition is complete, stir for 50-60min, and stir the solvent and thickener first After uniformity, the powder of the positive electrode material is added in batches. The coating device of the present invention can not only eliminate the air bubbles in the mixed slurry, make the coating more uniform and dense, but also make the thickness of the coating adjustable, and can be used to manufacture pole pieces with different discharge intensities; at the same time, the coating device increases The step of extruding the current collecting carrier coated with the mixed slurry by using the lower pressing roller and the upper pressing roller makes the mixed slurry more compact, thereby increasing the discharge time of the lithium battery, thereby increasing the life of the lithium battery.

Owner:淮北市智俊科技有限公司

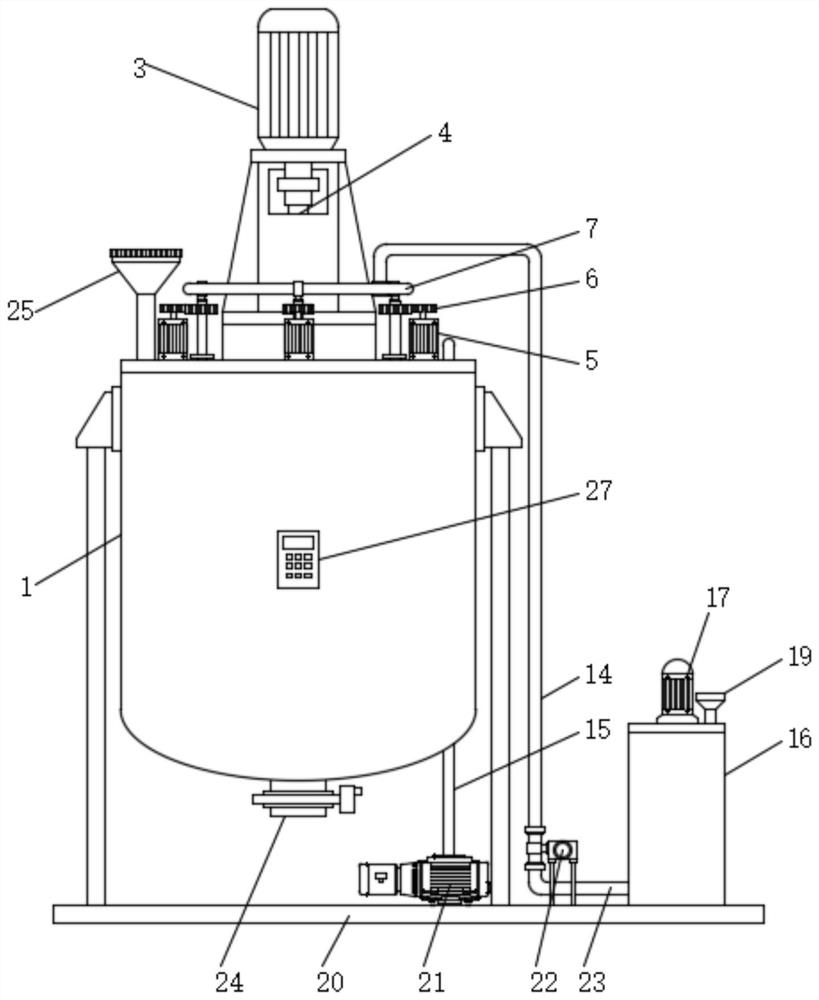

Defoaming device for outer wall surface water-based paint production

PendingCN114100410AEven contactRapid responseRotary stirring mixersTransportation and packagingProcess engineeringDefoaming Agents

The invention discloses a defoaming device for outer wall surface water-based paint production, the defoaming device comprises a dispersing tank and a base, the dispersing tank is fixedly mounted on the top surface of the base, a thinning tank is mounted on one side of the dispersing tank, and a coupling is fixedly mounted at the center of the top surface of the dispersing tank. The defoaming device has the beneficial effects that the thinning tank, the rotating pipe, the upper branch pipe and the lower branch pipe are adopted, a defoaming agent enters the rotating pipe from the conveying pipe and flows into the upper branch pipe and the lower branch pipe, the defoaming agent flowing into the upper branch pipe is sprayed above mixed liquid through the spray head, so that foam on the top surface of the mixed liquid is eliminated, meanwhile, the defoaming agent flowing into the lower branch pipe flows out of the leakage hole, and the defoaming effect is good. The defoaming agent is dispersed into the mixed liquid, so that foams in the mixed liquid can be conveniently eliminated during stirring and dispersing, the defoaming agent is uniformly sprayed and put from the inside and the outside of the mixed liquid, the defoaming agent is more uniformly contacted with the mixed liquid, the reaction is quicker, the effect of uniformly putting the defoaming agent for quickly defoaming is achieved, and the defoaming efficiency is further remarkably improved.

Owner:九江立帆科技有限公司

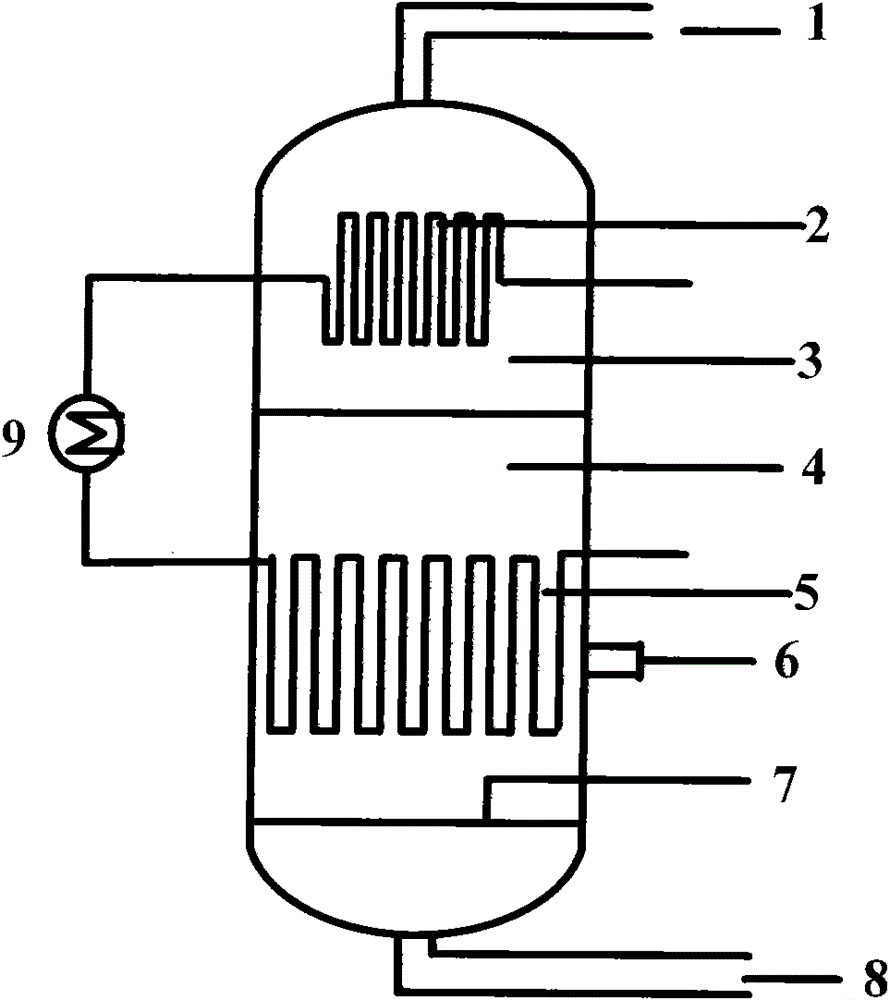

A slurry bed Fischer-Tropsch synthesis reactor

Owner:CHINA PETROLEUM & CHEM CORP +1

Composite mortar with anti-seismic function

The invention discloses a composite mortar with an anti-seismic function, which is prepared from, by weight, 50-65 parts of Portland cement, 35-45 parts of gypsum powder, 30-45 parts of slag powder, 25-35 parts of quartz sand, 25-30 parts of latex powder, 18-25 parts of slag powder, 15-25 parts of sepiolite, 6-10 parts of perlite, 5-10 parts of ceramic microbeads, 6-10 parts of wood fibers, 8-10 parts of PP fibers, 4-7 parts of polypropylene fiber, 5-10 parts of lithium bentonite, 7-10 parts of a water reducer, 8-12 parts of a binder, 3-5 parts of an expander, 2-4 parts of a defoamer, and 2-4parts of polyacrylamide. The composite mortar has excellent anti-seismic performance, saves resources, reduces the production cost, has the advantages of high strength, good uniformity, good bonding effect and good anti-cracking performance, and is beneficial to improving the quality of buildings.

Owner:广州六润建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com