Styrene copolymer emulsion for dip coating of glass fibers and preparation method and application of styrene copolymer emulsion

A technology of copolymer emulsion and glass fiber, which is applied in the field of glass fiber dip-coated styrene copolymer emulsion and its preparation, can solve the problems such as glass fiber alkali resistance, achieve good alkali resistance, reduce residue, fiber high intensity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

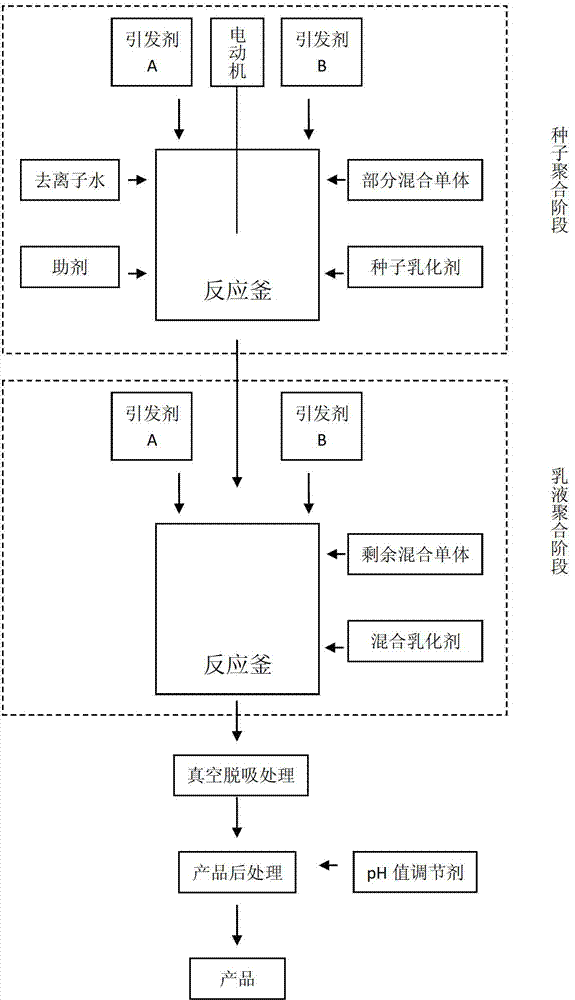

Method used

Image

Examples

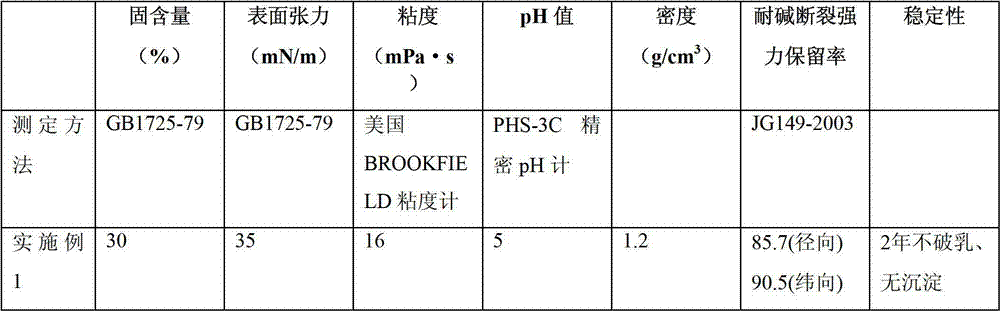

Embodiment 1

[0022] 1. Preparation of raw materials:

[0023] 1) Mixed monomer preparation: mix 42 kg of styrene, 6 kg of acrylonitrile, and 12 kg of butyl acrylate to obtain a mixed monomer;

[0024] 2) Initiator preparation: dissolving 240 g of potassium persulfate in 8 kg of water to obtain an aqueous solution of potassium persulfate, dissolving 240 g of sodium bisulfite in 8 kg of water to obtain an aqueous solution of sodium bisulfite;

[0025] 3) Mixed emulsifier preparation: Mix 600g of 2A-1 emulsifier and COPS-11.0kg and add water to 10kg to make a mixed emulsifier;

[0026] 2. Seed aggregation:

[0027] Add 105kg of water to the reaction kettle, add 50g of sodium dodecylsulfonate, 100g of OP-10, and 30g of ammonium acetate, seal the kettle, replace the gas three times, vacuumize, inhale the mixed monomer with a formula amount of 3%, cold disperse 0.5 h, heat up to 47°C, pump in the prepared potassium persulfate aqueous solution and sodium bisulfite aqueous solution, the addition...

Embodiment 2

[0033] 1. Preparation of raw materials:

[0034] 1) Mixed monomer preparation: Mix 56 kg of styrene, 8 kg of acrylonitrile, and 16 kg of butyl acrylate to obtain a mixed monomer;

[0035] 2) Initiator preparation: 260 g of potassium persulfate was dissolved in 8 kg of water to obtain an aqueous solution of potassium persulfate, and 260 g of sodium bisulfite was dissolved in 8 kg of water to obtain an aqueous solution of sodium bisulfite;

[0036] 3) Mixed emulsifier preparation: Mix 700g of 2A-1 emulsifier and COPS-11.0kg and add water to 10kg to make a mixed emulsifier;

[0037] 2. Seed aggregation:

[0038] Add 85kg of water to the reaction kettle, add 60g of sodium dodecylsulfonate, 120g of OP-10, and 30g of ammonium acetate, seal the kettle, replace the gas three times, vacuumize, inhale the mixed monomer with a formula amount of 3%, and cold disperse 0.5 h, heat up to 47°C, pump in the prepared potassium persulfate aqueous solution and sodium bisulfite aqueous solution,...

Embodiment 3

[0042] 1. Preparation of raw materials:

[0043] 1) Mixed monomer preparation: mix 42 kg of styrene, 6 kg of acrylonitrile, and 12 kg of methyl acrylate to obtain a mixed monomer;

[0044] 2) Initiator preparation: dissolving 240 g of potassium persulfate in 8 kg of water to obtain an aqueous solution of potassium persulfate, dissolving 240 g of sodium bisulfite in 8 kg of water to obtain an aqueous solution of sodium bisulfite;

[0045] 3) Mixed emulsifier preparation: Mix 600g of 2A-1 emulsifier and COPS-11.0kg and add water to 10kg to make a mixed emulsifier;

[0046] 2. Seed aggregation:

[0047] Add 105kg of water to the reaction kettle, add 50g of sodium dodecylsulfonate, 100g of OP-10, and 30g of ammonium acetate, seal the kettle, replace the gas three times, vacuumize, inhale mixed monomer with a formula amount of 3%, and cold disperse 0.5 h, heat up to 47°C, pump in the prepared potassium persulfate aqueous solution and sodium bisulfite aqueous solution, the additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com