Leaching tank stirring device having defoaming function

The technology of a stirring device and a leaching tank is applied in the directions of mixers with rotary stirring devices, accessories of mixers, improvement of process efficiency, etc., which can solve the problem of foam, adverse effects of the next process, and unsatisfactory defoaming effect of small bubbles. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

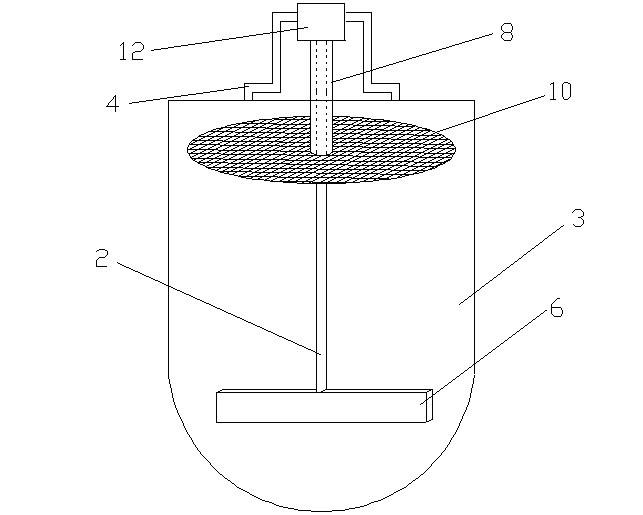

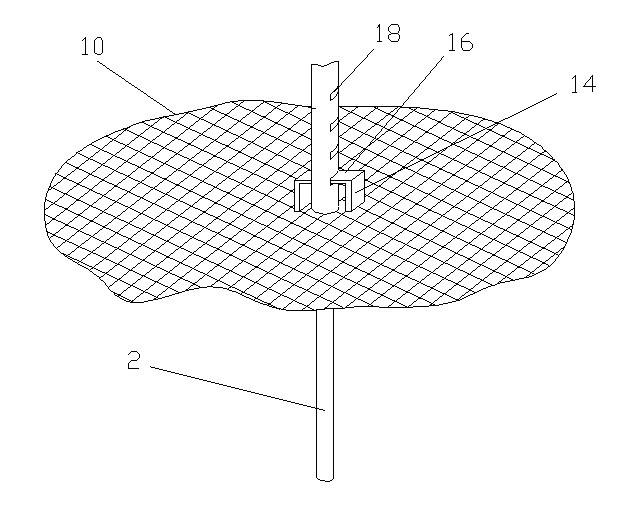

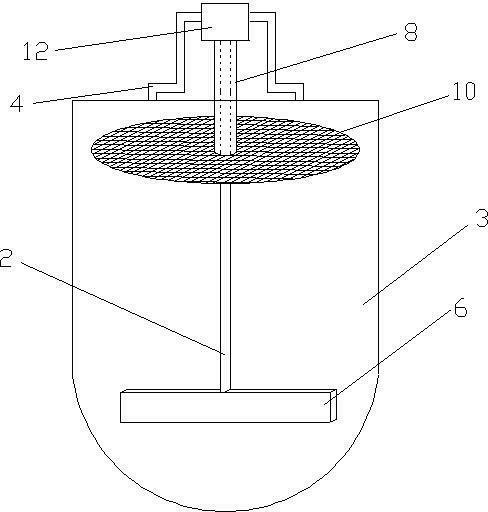

[0015] The present invention will now be described in further detail with reference to the drawings and embodiments. These drawings are simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, and therefore only show the constitutions related to the present invention.

[0016] Such as Figure 1-2 As shown, an leaching tank stirring device with defoaming function of the present invention includes a longitudinal stirring shaft 2, a first motor arranged at one end of the stirring shaft 2, a bracket 4 for fixing the entire stirring device, and a The other end of the shaft 2 is a stirring paddle 6 with the stirring shaft 2 as the rotating shaft. The stirring shaft 2 is sheathed with a cylindrical support shaft 8 fixed to the bracket 4, and the support shaft 8 is provided with a sheet-shaped defoaming net 10 perpendicular to the axis of the support shaft 8. The first motor is located in a case 12 arranged at one end of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com