A slurry bed Fischer-Tropsch synthesis reactor

A Fischer-Tropsch synthesis and reactor technology, applied in chemical instruments and methods, chemical/physical processes, etc., can solve problems such as optimization, and achieve the effects of improving conversion rate, reducing content, and accelerating diffusion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

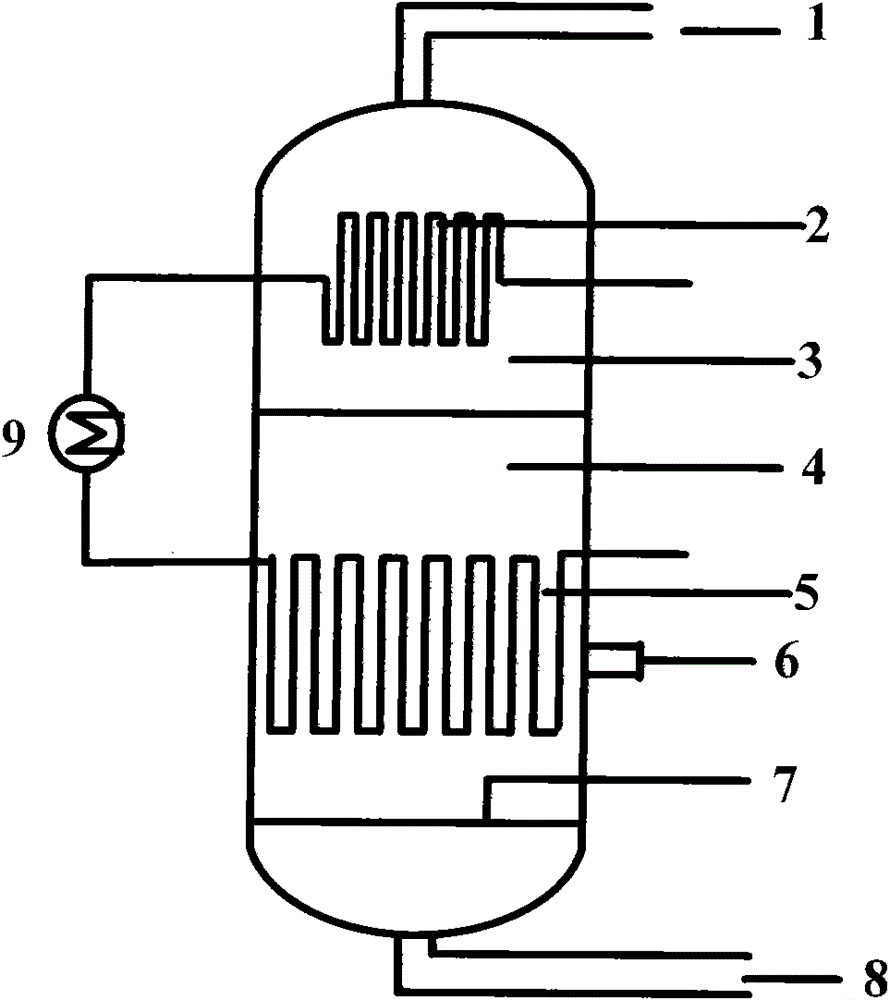

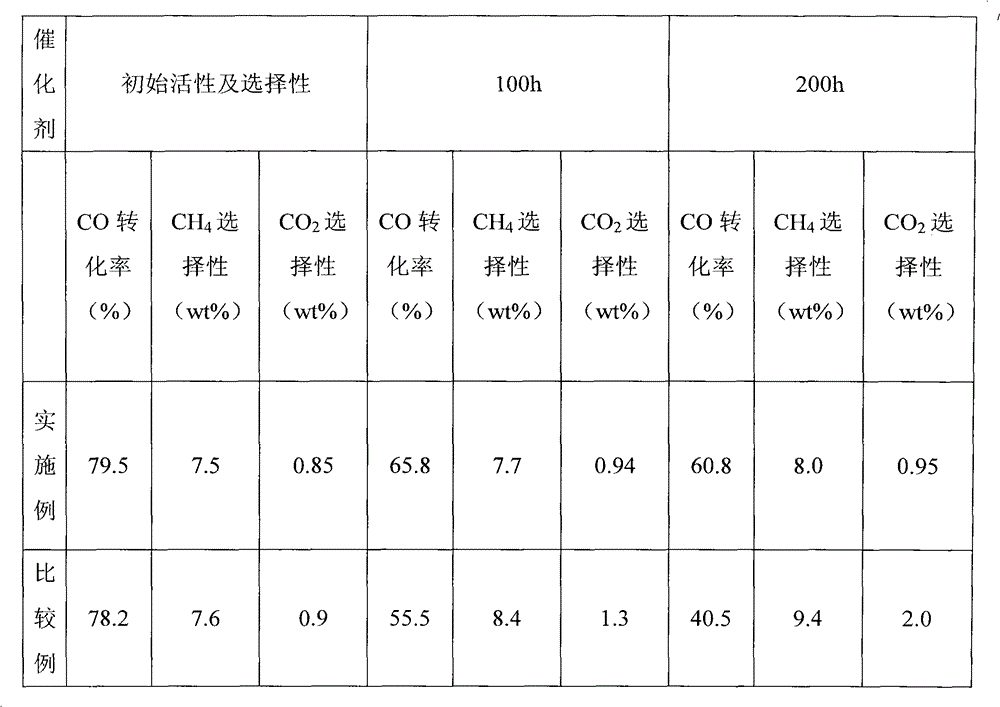

[0021] use figure 1 In the slurry bed Fischer-Tropsch synthesis reactor shown, the heating part of the gas-liquid diffusion section is a spiral coil heat exchange tube, the heating medium is the steam flowing out of the cooling coil in the reaction section, and the Fischer-Tropsch synthesis catalyst used is 20 %Co0.8%Pt / SiO 2 (Wt.), the reaction solvent is paraffin, the reaction temperature is 220°C, the reaction pressure is 2.0MPa, and the space velocity is 2.5Nm 3 / h / kg cat., H in syngas 2 / CO=2 (molar ratio), the gas-liquid diffusion section is heated through a spiral coil heat exchange tube, and light hydrocarbons and water vapor are heated to 230°C in the gas-liquid diffusion section. The conversion rate of carbon monoxide, methane selectivity, carbon dioxide selectivity and 200h stability test results are listed in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com