Tempered glass and manufacturing method thereof

A tempered glass and manufacturing method technology, applied in glass manufacturing equipment, manufacturing tools, glass production, etc., can solve the problems of poor effect of tiny bubbles in glass liquid, etc., to reduce bubbles, improve flexural strength, and high visibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

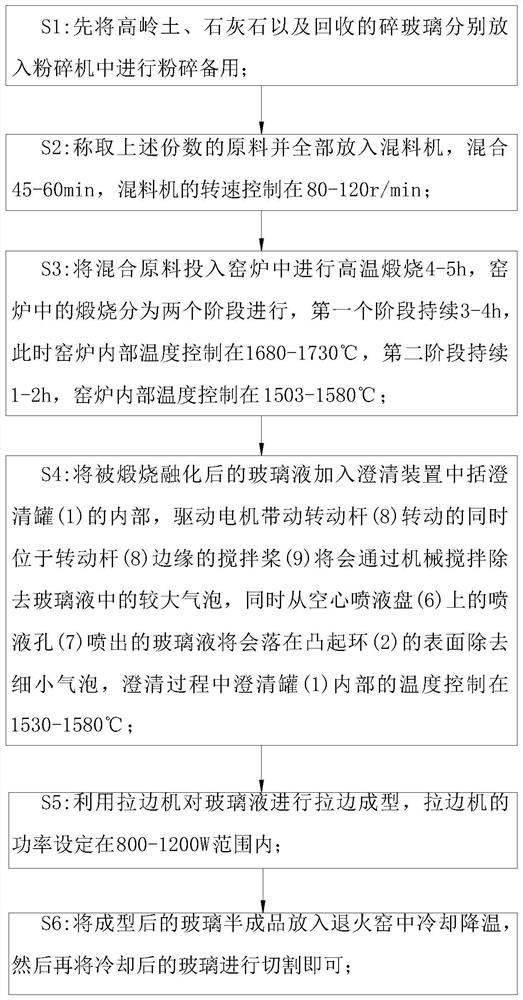

Method used

Image

Examples

Embodiment approach

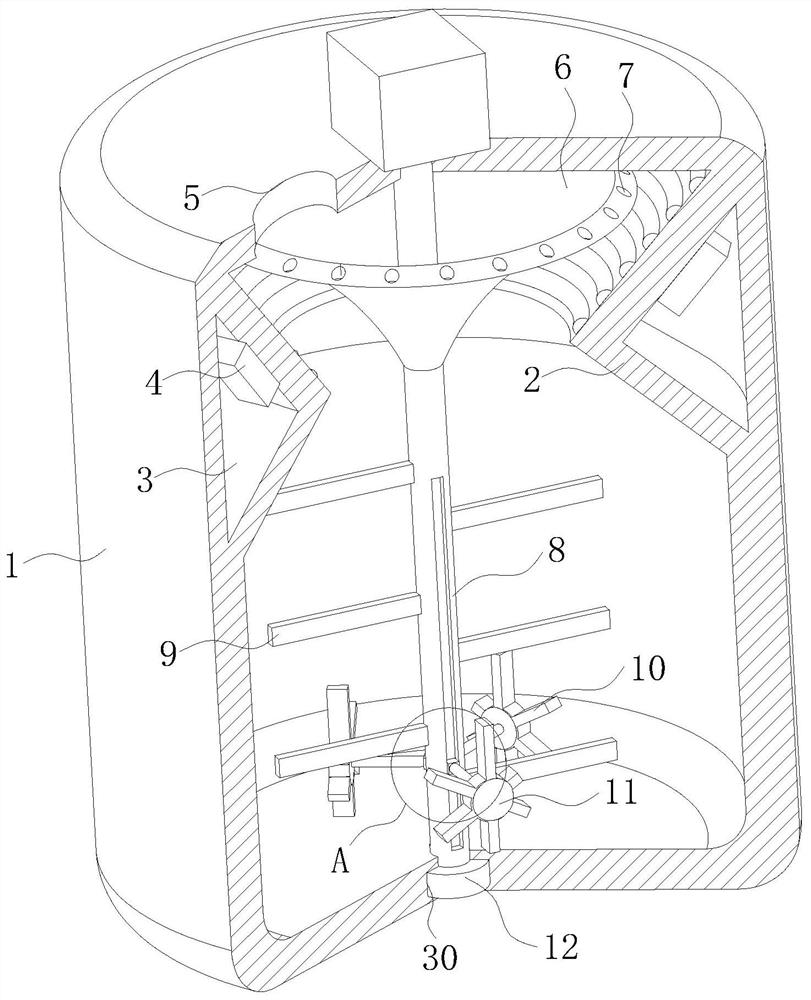

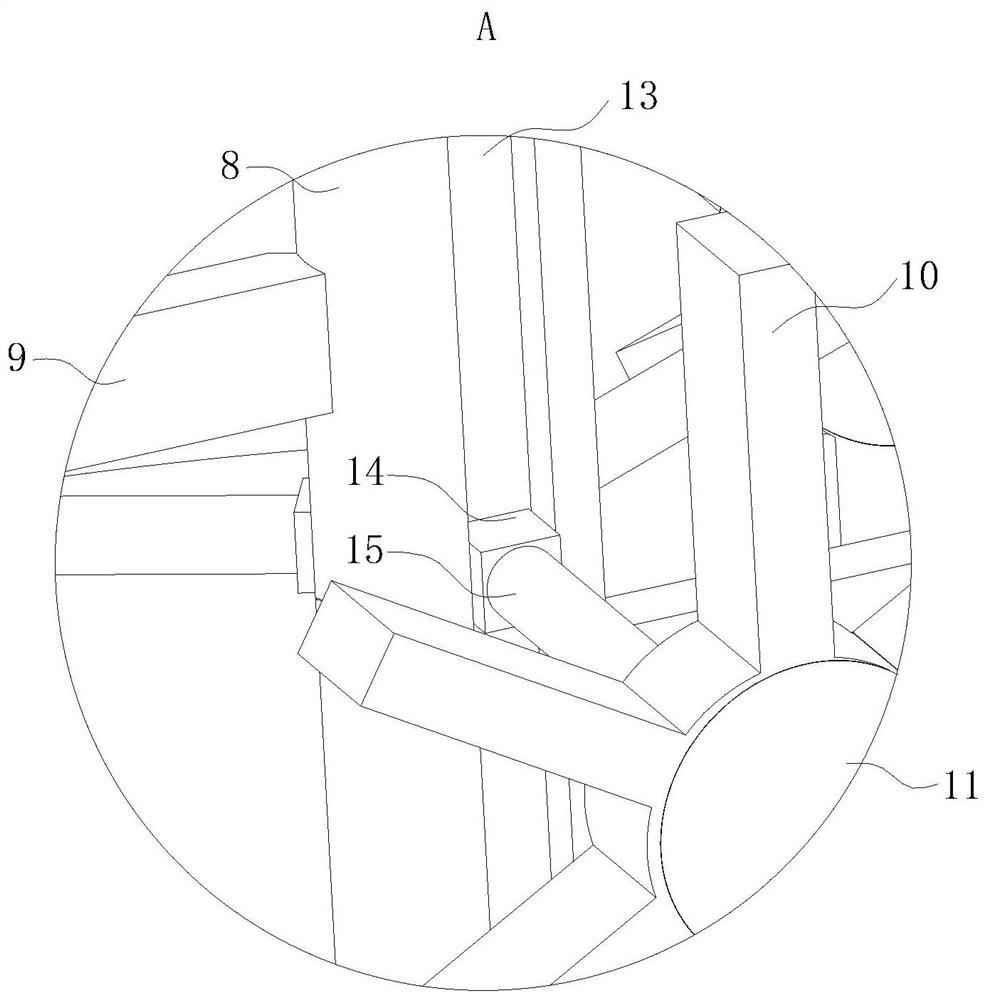

[0050] As an embodiment of the present invention, the edge of the rotating rod 8 is provided with a vertical chute 13; the inside of the vertical chute 13 is slidingly provided with a limit slider 14 at a position corresponding to the piston plate 25; The outer end of described limit slide block 14 is fixedly connected with an end of horizontal connecting rod 15, and the other end of horizontal connecting rod 15 is flexibly connected with the center position of the inner end of rotating disk 11; There are fan blades 10; the fan blades 10 are arranged in an equidistant ring on the edge of the rotating disc 11, and the length of the fan blades 10 on the rotating disc 11 increases in a clockwise direction; the inside of the piston plate 25 is fixed with a magnet 31; the limit slider 14 is made of ferromagnetic material; when working, when the piston plate 25 moves up and down, the magnet 31 inside the piston plate 25 will drive the limit slider 14 to move up and down, thereby maki...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com