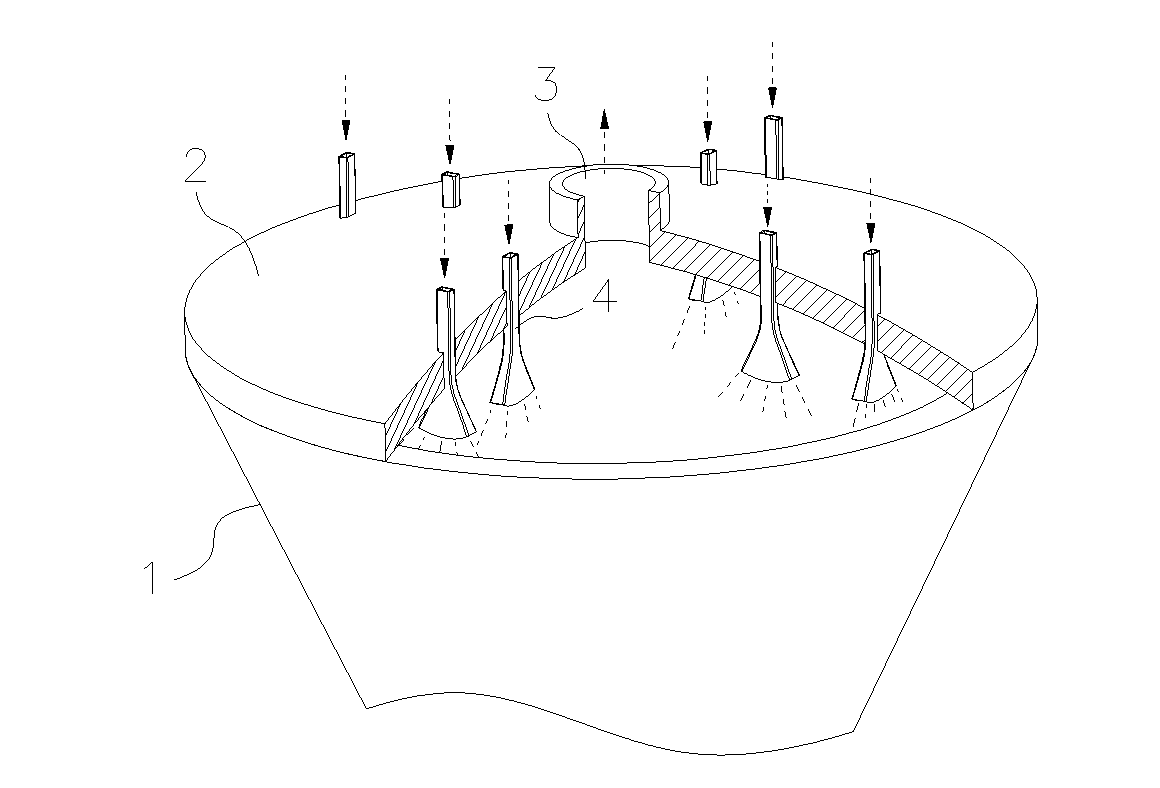

Cover type defoamer and acidolysis process for preparing titanium white powder by sulfuric acid method

A defoamer and hood-type technology, applied in the field of acid hydrolysis process, can solve the problems of hidden safety hazards, poor defoaming effect, reduced production capacity, etc., and achieve the effect of restraining growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

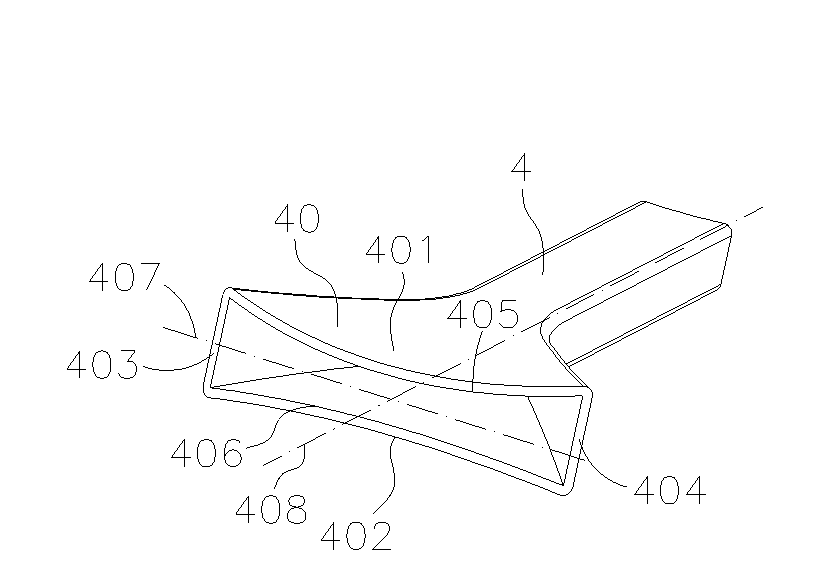

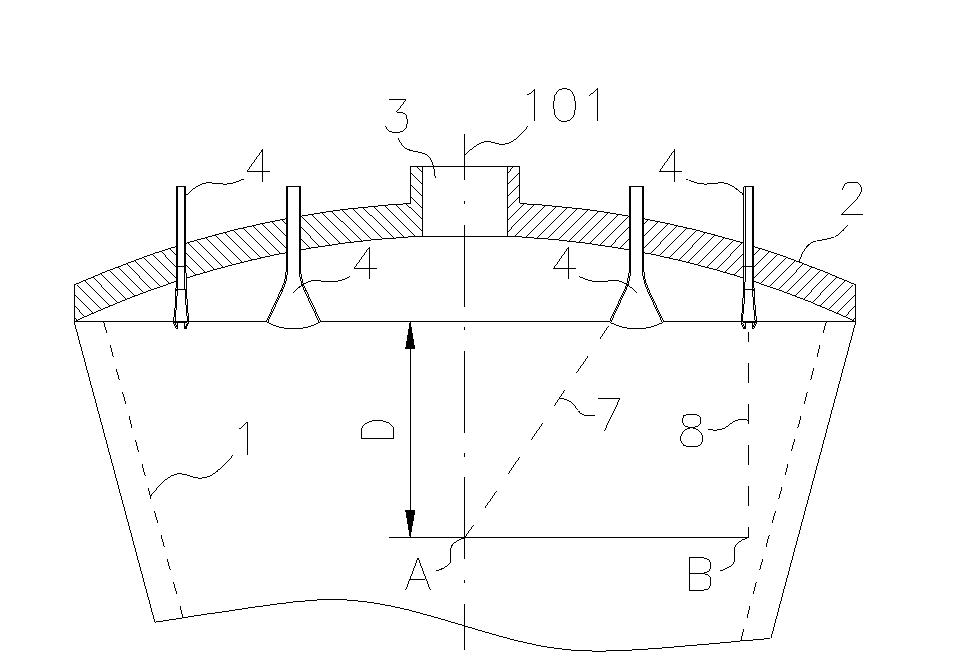

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: the volume is 30m 3Put 12.9t of concentrated sulfuric acid with a concentration of 92% into the acid hydrolysis pot, turn on the compressed air to stir, and then put 7.8t of titanium concentrate into the acid hydrolysis pot; when the concentrated sulfuric acid and titanium concentrate are mixed evenly, add starting water to trigger Main reaction; when the main reaction is about to occur, open the valve K3, and blow the compressed air into the acidolysis pot through the compressed air defoaming spray gun 4. According to the actual situation of the reaction, the blowing amount of compressed air can be adjusted appropriately; after the main reaction is over, close the valve K3, the compressed gas defoaming spray gun 4 stops spraying.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com