Aqueous antiseptic metal undercoat polyvinyl dichloride (PVDC) copolymer emulsion and preparation method thereof and application

A copolymer emulsion and metal technology, applied in the direction of anti-corrosion coatings, coatings, etc., can solve the problems of unsuitable large-scale industrial production, complex synthesis process of water-based paint, high synthesis cost, etc., achieve low cost, improve stability, and volatile organic compounds The effect of low content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

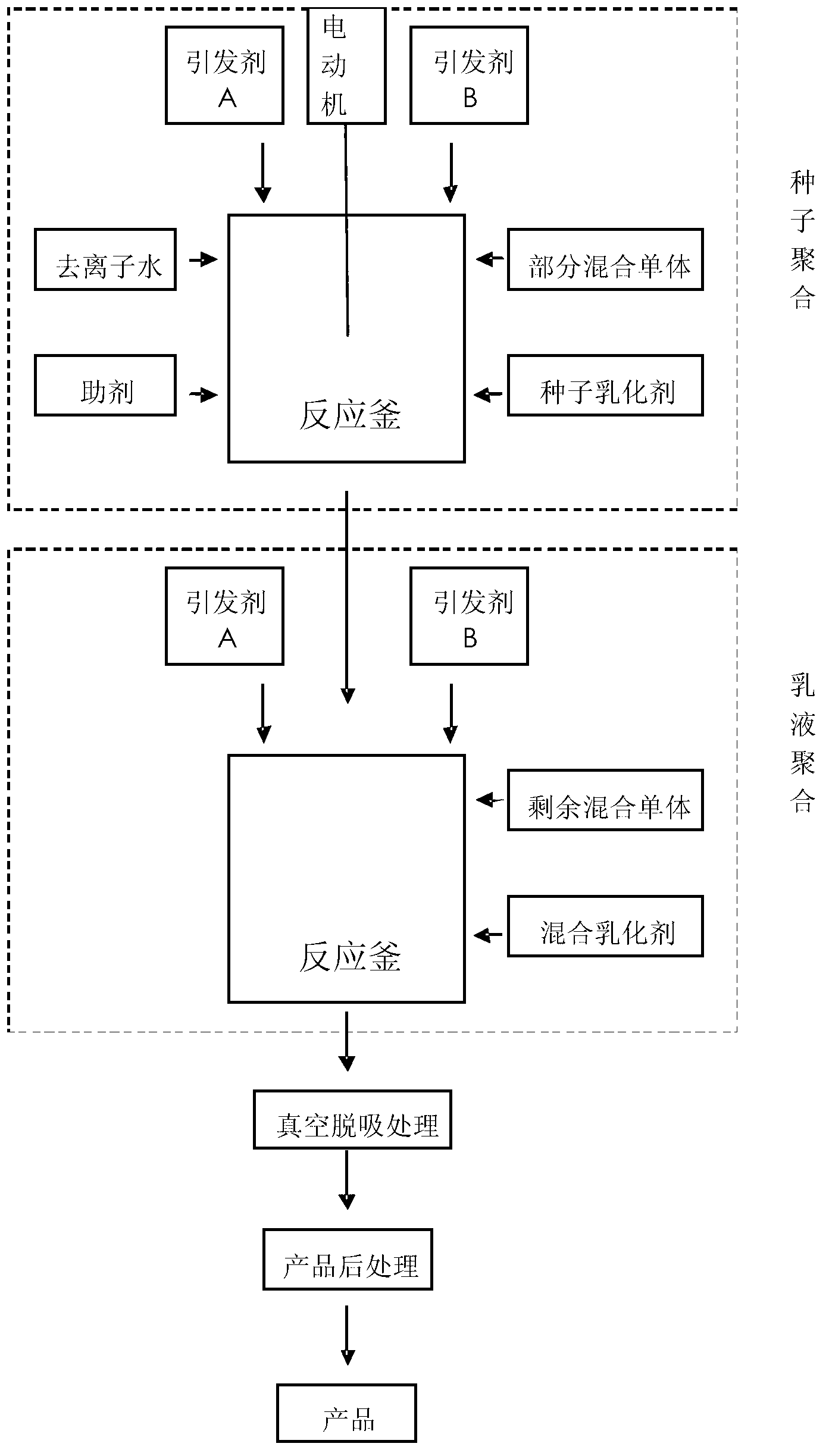

Method used

Image

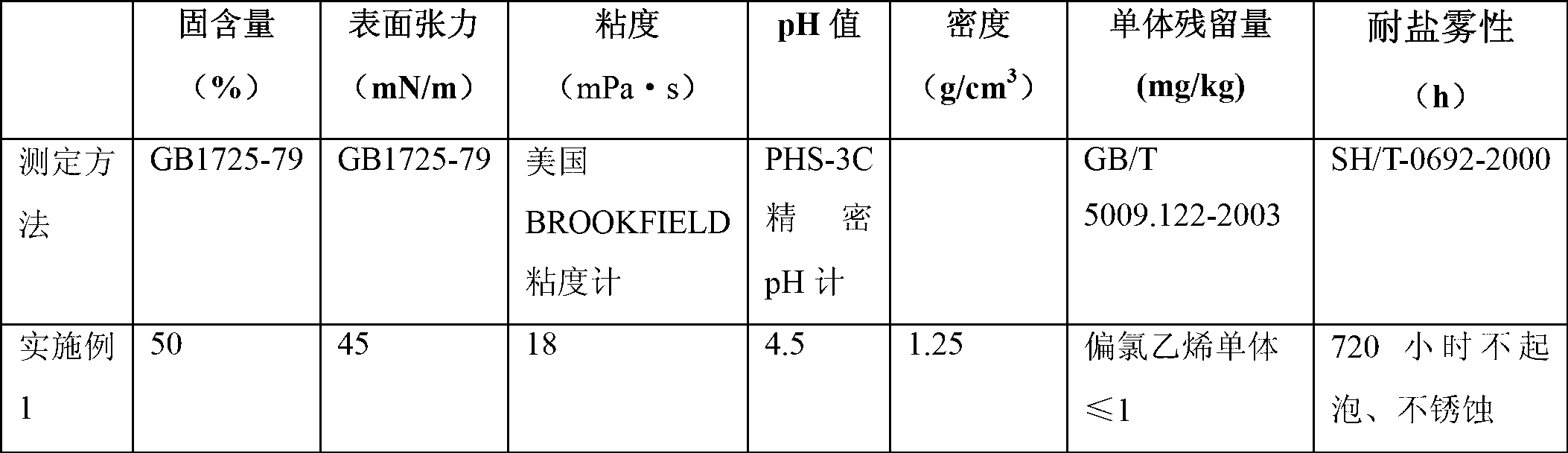

Examples

Embodiment 1

[0022] 1. Raw material preparation:

[0023] 1) Mixed monomer preparation: mix 92 kg of vinylidene chloride, 4 kg of methyl methacrylate, and 0.5 kg of acrylonitrile to obtain a mixed monomer;

[0024] 2) Preparation of initiator: dissolve 160 g of tert-butyl hydroperoxide in 8 kg of water to obtain an aqueous solution of tert-butyl hydroperoxide, and dissolve 160 g of sodium formaldehyde sulfoxylate in 8 kg of water to obtain an aqueous solution of sodium formaldehyde sulfoxylate;

[0025] 3) Preparation of mixed emulsifier: mix 1.2 kg of AMPS and 1 kg of 2A-1 emulsifier, add 3.5 kg of acrylic acid, and add water to 20 kg to prepare a mixed emulsifier;

[0026] 2. Seed aggregation:

[0027] Add 64kg of water to the reaction kettle, add 120g of sodium dodecylbenzene sulfonate, OP-10280g, 30g of glacial acetic acid, 1g of ferrous chloride, seal the kettle, replace the gas 3 times, evacuate, and inhale a mixture of 5% of the formula The monomer, cold dispersion for 0.5h, heated to 47℃, p...

Embodiment 2

[0032] 1. Raw material preparation:

[0033] 1) Mixed monomer preparation: mixed vinylidene chloride 110.4 kg, methyl acrylate 4.8 kg, and acrylonitrile 0.6 kg to obtain mixed monomer; 2) initiator preparation: dissolve 220 g of tert-butyl hydroperoxide in 8 kg of water to obtain a mixed monomer Dissolve 220 g of sodium formaldehyde sulfoxylate in 8 kg of water in tert-butyl hydrogen peroxide aqueous solution to obtain an aqueous solution of sodium formaldehyde sulfoxylate;

[0034] 3) Preparation of mixed emulsifier: mix 1.5 kg of AMPS and 1.2 kg of 2A-1 emulsifier, add 4.2 kg of acrylic acid, and add water to 20 kg to prepare a mixed emulsifier;

[0035] 2. Seed aggregation:

[0036] Add 44kg of water to the reaction kettle, add 150g of sodium dodecylbenzene sulfonate, OP-10300g, 30g of glacial acetic acid, 1g of ferrous chloride, seal the kettle, replace the gas 3 times, vacuum, and inhale a mixture of 5% of the formula The monomer, cold dispersion for 0.5h, heated to 47℃, pumped ...

Embodiment 3

[0040] 1. Raw material preparation:

[0041] 1) Mixed monomer preparation: mix 92 kg of vinylidene chloride, 4 kg of butyl methacrylate, and 0.5 kg of acrylonitrile to obtain a mixed monomer;

[0042] 2) Preparation of initiator: dissolve 160 g of tert-butyl hydroperoxide in 8Kg of water to obtain an aqueous solution of tert-butyl hydroperoxide, and dissolve 160 g of sodium formaldehyde sulfoxylate in 8 kg of water to obtain an aqueous solution of sodium formaldehyde sulfoxylate;

[0043] 3) Preparation of mixed emulsifier: mix 1.2 kg of AMPS and 1 kg of 2A-1 emulsifier, add 3.5 kg of acrylic acid, and add water to 20 kg to prepare a mixed emulsifier;

[0044] 2. Seed aggregation:

[0045] Add 64kg of water to the reaction kettle, add 120g of sodium dodecylbenzene sulfonate, OP-10 280g, 30g of glacial acetic acid, 1g of ferrous chloride, seal the kettle, replace the gas 3 times, vacuum, and suck 5% of the formula Mix the monomers, cold disperse for 0.5h, heat up to 47℃, pump in the pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com