Preparation method of super-concentrated carboxyl-based ester-based emulsion polymer

A technology of emulsion polymer and concentrated carboxyl group, applied in polyether coatings, coatings, etc., can solve problems such as difficulty in achieving film-forming smoothness and adaptability, and achieve the effect of tight combination, good fluidity, and improved bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

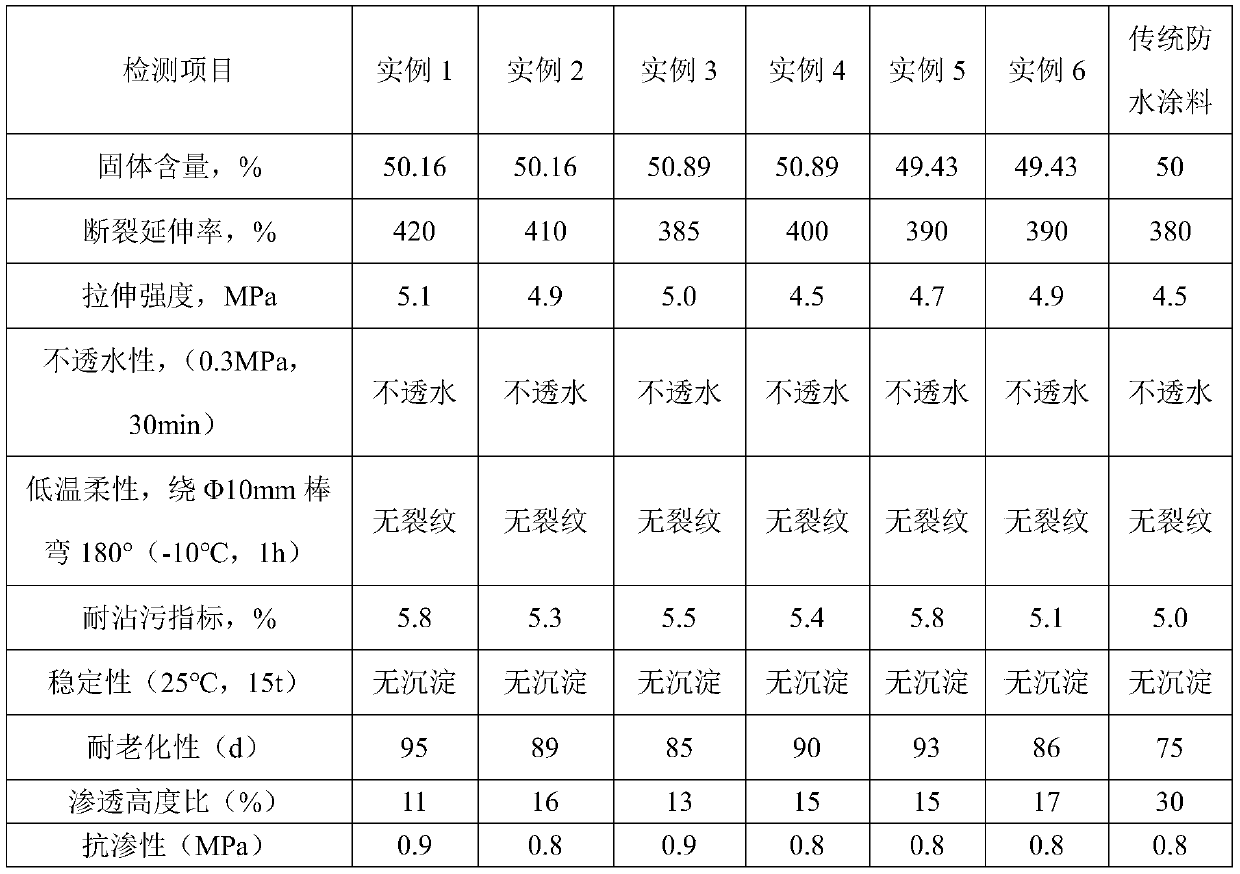

Examples

example 1

[0070] Prepare a kind of raw material of carboxylate polymer waterproof coating, comprise the component of following mass parts:

[0071] 1.7 parts of the composition of acrylic acid and fumaric acid with a mass ratio of 1:3;

[0072] 3.9 parts of the composition of lauryl (meth)acrylate and 2-ethylhexyl (meth)acrylate with a mass ratio of 2:3;

[0073] 16 parts of compositions of itaconic acid and aconitic acid whose mass ratio is 1:1;

[0074] 395 parts of the composition of 2-phenoxyethyl methacrylate and 2-methacryloyloxyethyl ester with a mass ratio of 1:2;

[0075] 0.07 parts of the composition of dicyclohexyl peroxydicarbonate and tert-butyl peroxy t-valerate in a mass ratio of 1:1;

[0076] 2.4 parts of the composition of azobisisobutyronitrile and dimethyl azobisisobutyrate with a mass ratio of 3:2;

[0077] 6.3 parts of the composition of azobiscyanovaleric acid and azobisisoheptanonitrile with a mass ratio of 2:3;

[0078] 7.1 parts of compositions of 1,3-bis(4-...

example 2

[0099] Prepare a kind of raw material of carboxylate polymer waterproof coating, comprise the component of following mass parts:

[0100] 1.7 parts of methacrylic acid;

[0101] 3.9 parts of 2-ethylhexyl (meth)acrylate;

[0102] 16 parts of compositions of itaconic acid and aconitic acid whose mass ratio is 1:1;

[0103] 395 parts of the composition of 2-phenoxyethyl methacrylate and 2-methacryloyloxyethyl ester with a mass ratio of 1:2;

[0104] 0.07 parts of lauryl peroxide;

[0105] 2.4 parts of the composition of azobisisobutyronitrile and dimethyl azobisisobutyrate with a mass ratio of 3:2;

[0106] 6.3 parts of azodicyanovaleric acid;

[0107] 7.1 parts of compositions of 1,3-bis(4-aminophenoxy)propane and diaminododecylbenzene in a mass ratio of 2:1;

[0108] Sodium hypophosphite 0.12 parts;

[0109] 5.5 parts of hydroxyethyl pyrphthalic anhydride dimethacrylate;

[0110] 4.5 parts of compositions of stearyl methacrylate and stearyl acrylate with a mass ratio of ...

example 3

[0128] Prepare a kind of raw material of carboxylate polymer waterproof coating, comprise the component of following mass parts:

[0129] 1.2 parts of fumaric acid;

[0130] 5.4 parts of n-butyl (meth)acrylate;

[0131] 30 parts of maleic acid;

[0132] 410 parts of the composition of 2-phenoxyethyl methacrylate and 2-methacryloyloxyethyl ester with a mass ratio of 1:2;

[0133] 0.13 parts of tert-butyl peroxy tert-valerate;

[0134] 3.8 parts of azobisisobutyric acid;

[0135] 3.6 parts of azobisisoheptanonitrile;

[0136] 6.9 parts of cyclobutane tetracarboxylic dianhydride;

[0137] 0.23 parts of sodium hypophosphite;

[0138] 6.1 parts of two (methacryloyloxyethyl) pyrphthalic anhydride esters;

[0139] 3.5 parts of cetyl alcohol;

[0140] 0.7 part of polyvinyl alcohol;

[0141] 23 parts of copolyether of ethylene oxide and propylene oxide with a mass ratio of 1:1;

[0142] 0.7 part of graphene oxide;

[0143] 12.56 parts of super concentrated emulsifier;

[01...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com