Heat-resistant, sun-proof and high-color-fastness polymeric dye for leather

A polymer dye, high color fastness technology, used in the preparation of high color fastness polymer dyes, leather heat-resistant, sun-resistant fields, can solve the problem of easy migration, poor dry and wet rubbing performance, solvent intolerant, etc. problem, to achieve the effect of good sun resistance, improved heat resistance, and excellent UV protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

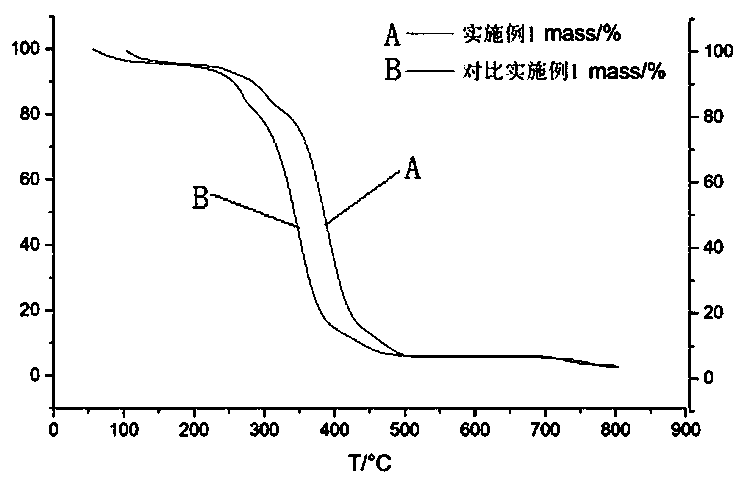

Image

Examples

Embodiment 1

[0030] (1) Add the dried graphene oxide dry powder into water, and disperse it on a 600w power ultrasonic disperser for 1 hour. The mass fraction of graphene oxide in the graphene oxide aqueous solution is 0.5%.

[0031] (2) Add 150 parts of toluene diisocyanate, 15 parts of polyester polyol 400, 50 parts of polyether polyol 600, and 30 parts of acetone into the reaction kettle equipped with a condensation reflux device, and heat up to 85°C for 1.5 hours. Then cool down to 50°C, then add 40 parts of 2,2-dimethylolpropionic acid for chain extension, 0.1 part of tin catalyst T-9, heat up to 80°C, and react for 2.0 h; cool down to 50°C, add 15 parts of weak acid Black BG was subjected to capping reaction, heated to 80°C for 2.0 h, cooled to room temperature, added 42 parts of triethylamine, continued to react for 0.5 h, poured the reaction product into an emulsification tank, added 5000 parts of deionized water and deionized Graphene oxide water dispersion of the same quality as ...

Embodiment 2

[0034] (1) Add the dried graphene oxide dry powder into water, and disperse it on a 400w power ultrasonic disperser for 2.0 h. The mass fraction of graphene oxide in the graphene oxide aqueous solution is 0.3%.

[0035] (2) Add 40 parts of isophorone diisocyanate, 90 parts of hexamethylene diisocyanate, 15 parts of polyester polyol 600, 50 parts of polyether polyol 1000, and 40 parts of acetone, heat up to 85°C for 2.0 h, then cool down to 50°C, add 40 parts of 2,2-dimethylol propionic acid for chain extension, 0.1 part of dibutyltin dilaurate, heat up to 85°C, react for 2.0 h; cool down to 50°C, add 10 parts of solvent black 34 for capping reaction, raise the temperature to 75°C for 2.5 hours, add 45 parts of diethanolamine after cooling to room temperature, continue the reaction for 0.3h, then pour the reaction product into the emulsification tank , adding 6500 parts of deionized water and a graphene oxide water dispersion of the same quality as the deionized water, stirring...

Embodiment 3

[0038] (1) Add the dried graphene oxide dry powder into water, and disperse it on a 400w power ultrasonic disperser for 2.0 h. The mass fraction of graphene oxide in the graphene oxide aqueous solution is 0.4%.

[0039] (2) Add 120 parts of diphenylmethane diisocyanate, 5 parts of polyester polyol 200, 60 parts of polyether polyol 800, and 40 parts of acetone into the reaction kettle equipped with a condensation reflux device, and heat up to 85°C for reaction 2.0 h, then lower the temperature to 50°C, then add 35 parts of 2,2-dimethylol propionic acid for chain extension, 0.1 part of tin catalyst T-9, raise the temperature to 80°C, react for 2.0 h; cool down to 50°C, add 7 Acidic yellow G was subjected to capping reaction, heated to 75°C for 2.5 hours, cooled to room temperature and then added with 45 parts of potassium hydroxide (potassium hydroxide was first dissolved with an appropriate amount of water and cooled for later use), and the reaction was continued for 0.3 hours, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com