Environment-protection weather-proof self-temperature-sensitive fireproof cable and manufacturing method thereof

A fire-resistant cable, warm-type technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the problems of poor extrusion resistance of the fire-proof mud isolation layer, waste of time and production costs, and the insulation mica tape is easy to be affected by moisture, etc., to achieve protection Normal power supply, slow down heat conduction, excellent low-smoke, halogen-free flame retardant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

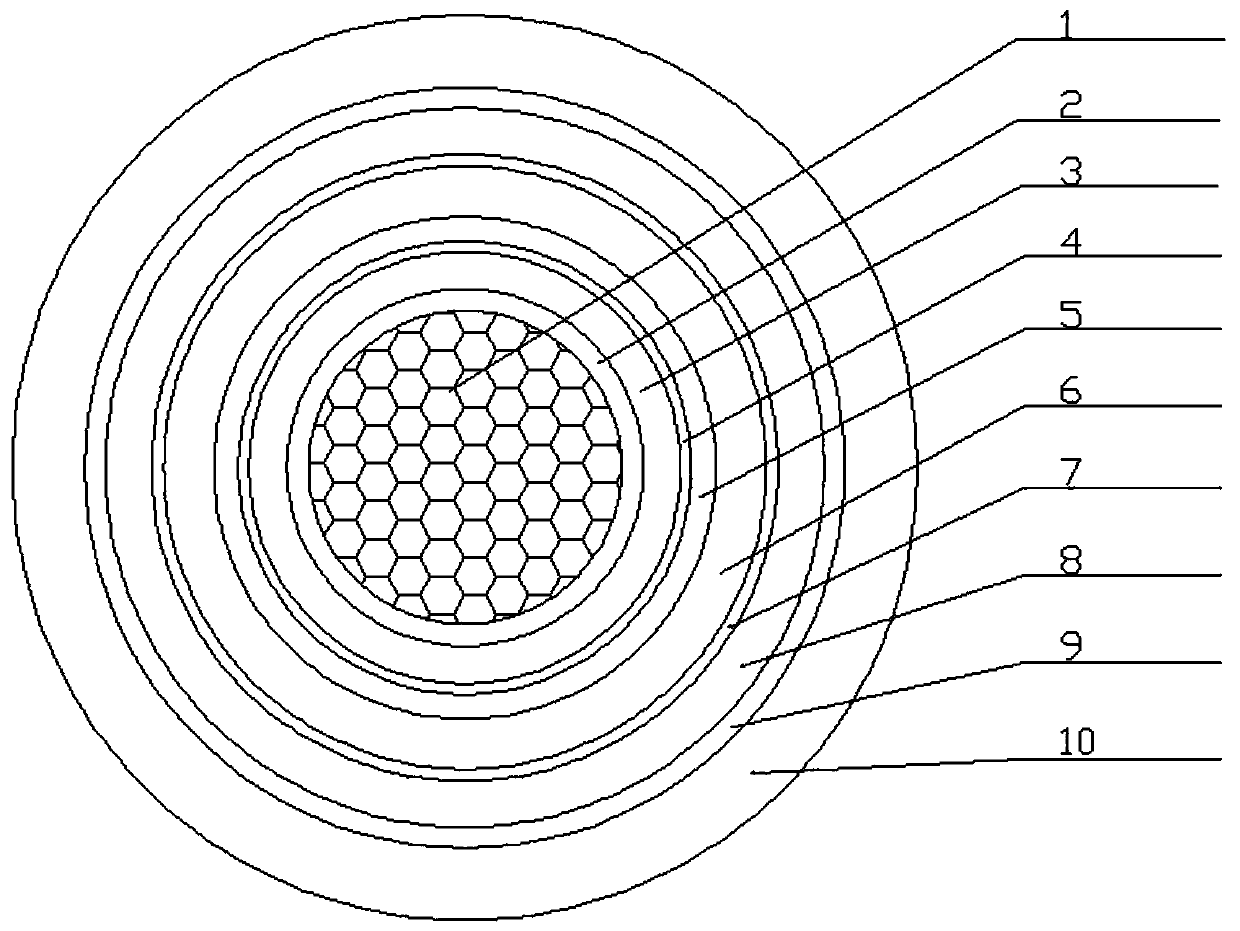

[0023] An environment-friendly, weather-resistant, self-inductive temperature-resistant fireproof cable (see attached figure 1 ), including wire core, inner halogen-free tape 4, aluminum sheath 5, fireproof mud isolation layer 6, middle halogen-free tape 7, steel belt interlocking armor layer 8, outer halogen-free tape 9, outer sheath 10 , the outer side of the wire core is covered with an inner halogen-free tape, the outer side of the inner halogen-free tape is covered with an aluminum sheath, the outer side of the aluminum sheath is extruded with a fireproof mud isolation layer, and the outer side of the fireproof mud isolation layer is wrapped Equipped with medium-halogen-free tape, the outer side of the medium-halogen-free tape is covered with a steel belt interlocking armor layer, the outer side of the steel-belt interlocking armor layer is covered with an outer halogen-free tape, and the outer side of the outer halogen-free tape is wrapped An outer sheath is provided, an...

Embodiment 2

[0027] This embodiment is an environment-friendly, weather-resistant, self-temperature-sensitive fireproof cable with multi-core insulated wire cores, which is basically the same as Embodiment 1, except that in this embodiment, the number of wire cores is greater than 2. In this embodiment, the wire The number of cores is 4, and all the cores are wrapped by the inner halogen-free tape, and the inner space of the inner halogen-free tape is filled with a filler rope.

Embodiment 3

[0029]In this embodiment, the parameters of the added color masterbatch are manually adjusted according to the parameters of the environmentally friendly weather-resistant self-temperature-sensitive fireproof cable, so that the insulating layer changes from black to transparent when the temperature exceeds 60°C or 55°C and other artificially set temperatures Color, through the perception of temperature to cause color changes to play a visible safety warning role.

[0030] A method for manufacturing an environment-friendly weather-resistant self-temperature-sensing fireproof cable, which is used to make the above-mentioned environment-friendly weather-resistant self-temperature-sensing fireproof cable, comprising the following steps:

[0031] Step 1: Press the circular copper conductor tightly, wrap two layers of mica tape on the outside of the copper conductor, and extrude ceramic flame-retardant polyolefin insulation material as a composite insulation fireproof layer;

[0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com