A kind of preparation method of carbon molecular sieve

A carbon molecular sieve and particle technology, which is applied in the field of molecular sieve preparation, can solve the problems of pore-adjusting agent residual pollution, uneven pores, etc., and achieve the effects of increasing agricultural income, fine and uniform pores, and expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

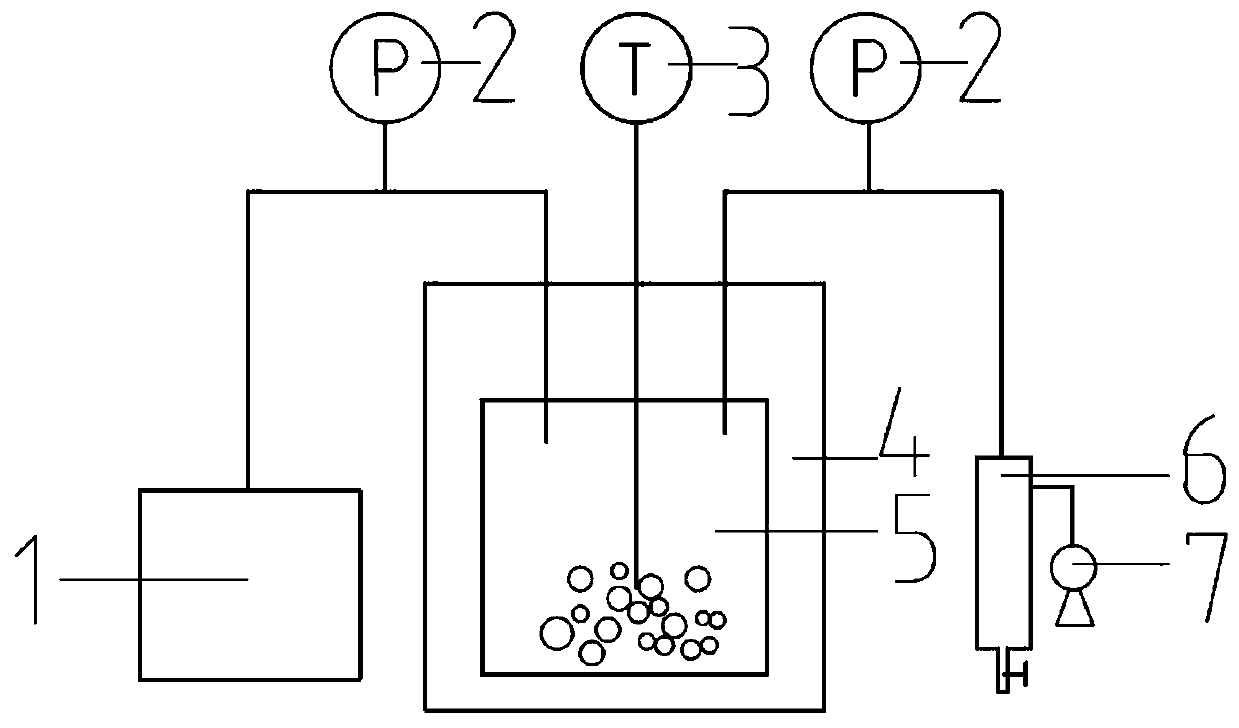

Method used

Image

Examples

Embodiment 1

[0032] Grind 70g of walnut shells and 30g of chestnut shells, dry them until the weight deviation of 3 weighings does not exceed 0.1g, and obtain powdered shell materials a with a particle size of 3 μm, dry distillation and ball milling of 25g of polyvinylidene chloride resin Obtain powdery polyvinylidene chloride resin b with a particle size of 3 μm;

[0033] Stir a, b, 9g tar, 0.4PVA, 0.6g starch and 22.5g water evenly, put them into a hydraulic press and extrude to obtain cylindrical particles with an average diameter of 1.5mm and an average length of 4mm, then place the cylindrical particles In a drying oven, dry at 200°C for 1.5h to obtain dry cylindrical particles c. Put the dried cylindrical particles c into a horizontal converter and raise the temperature under the protection of nitrogen. The heating rate is set at 11°C / min, and the temperature is raised to After 450°C, set the heating rate to 5°C / min, raise the temperature to 700°C, and keep the temperature constant f...

Embodiment 2

[0036] Grind 70g of walnut shells and 30g of chestnut shells, dry them until the weight deviation of 3 weighings does not exceed 0.1g, and obtain shell powder raw material a with a particle size of 3 μm, dry distillation and ball milling of 25g of polyvinylidene chloride resin Obtaining polyvinylidene chloride resin powder raw material b with a particle size of 3 μm;

[0037] Stir a, b, 8.5g tar, 0.5PVA, 1.0g starch and 22.5g water evenly, put them into a hydraulic press and extrude to obtain cylindrical particles with an average particle diameter of 2mm and an average length of 3.8mm, and then the cylindrical particles Place in a drying oven and dry at 230°C for 2 hours to obtain dry cylindrical particles c. Put the dried cylindrical particles c into a horizontal converter and raise the temperature under the protection of nitrogen. The heating rate is set at 11°C / min, and the temperature is raised to After 450°C, set the heating rate to 5°C / min, raise the temperature to 680°C...

Embodiment 3

[0040] Grind 70g of walnut shells and 30g of chestnut shells, dry them until the weight deviation of 3 weighings does not exceed 0.1g, and obtain shell powder raw material a with a particle size of 3 μm, dry distillation and ball milling of 25g of polyvinylidene chloride resin Obtaining polyvinylidene chloride resin powder raw material b with a particle size of 3 μm;

[0041]Stir a, b, 9.5g tar, 0.3PVA, 0.2g starch and 22.5g water evenly, put them into a hydraulic press and extrude to obtain cylindrical particles with an average particle diameter of 1.5mm and an average length of 4.5mm, and then cylindrical The particles were placed in a drying oven and dried at 250°C for 1.5 hours to obtain dry cylindrical particles c. Put the dried cylindrical particles c into a horizontal converter and raise the temperature under the protection of nitrogen. The heating rate was set at 11°C / min. After raising the temperature to 450°C, set the heating rate to 5°C / min, raise the temperature to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com