Environmental-protection oxygen barrier antibacterial polypropylene-random (PP-R) pipe

A PP-R, oxygen barrier technology, applied in the direction of pipes, rigid pipes, pipes/pipe joints/fittings, etc., can solve the problems of PP-R pipe distortion, easy adhesion to metal surfaces, affecting service life, etc. Good high temperature and pressure resistance, long antibacterial time and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

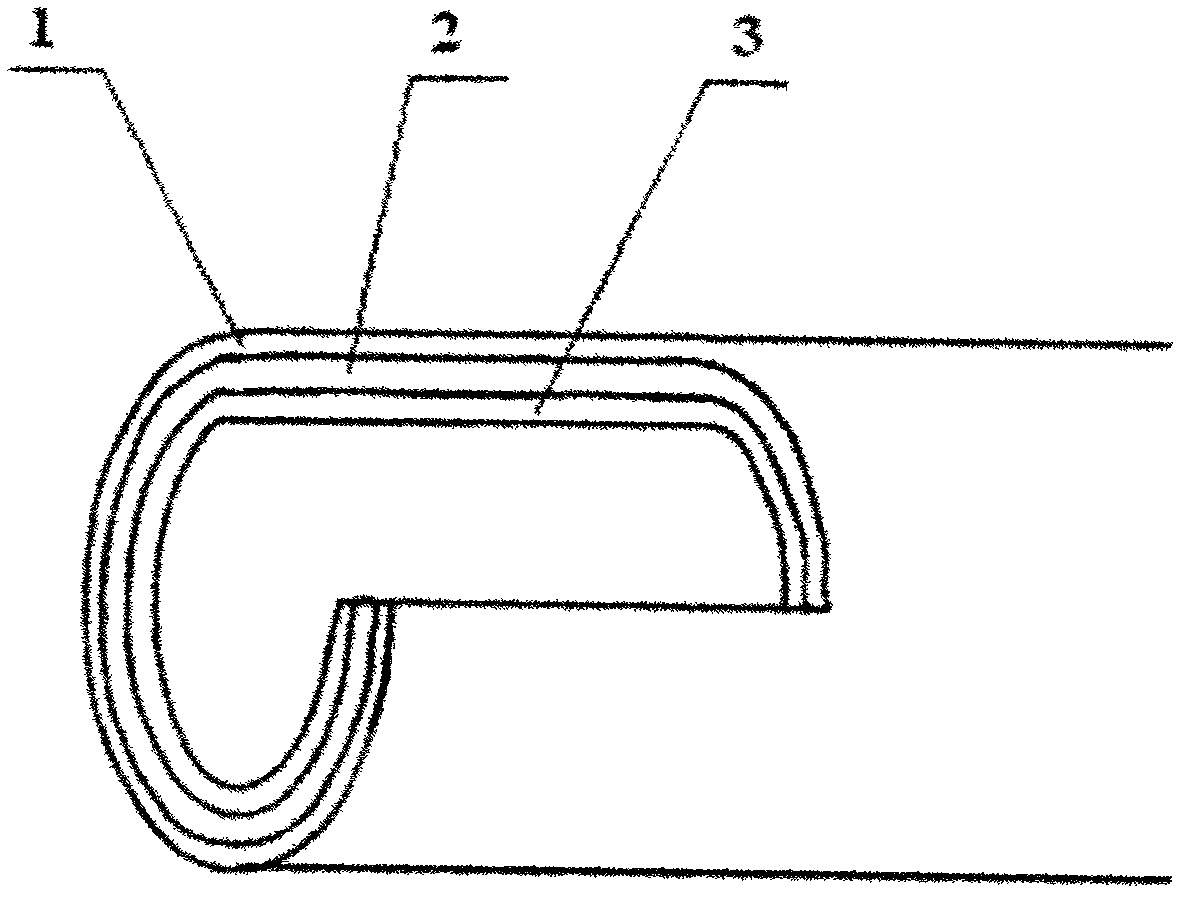

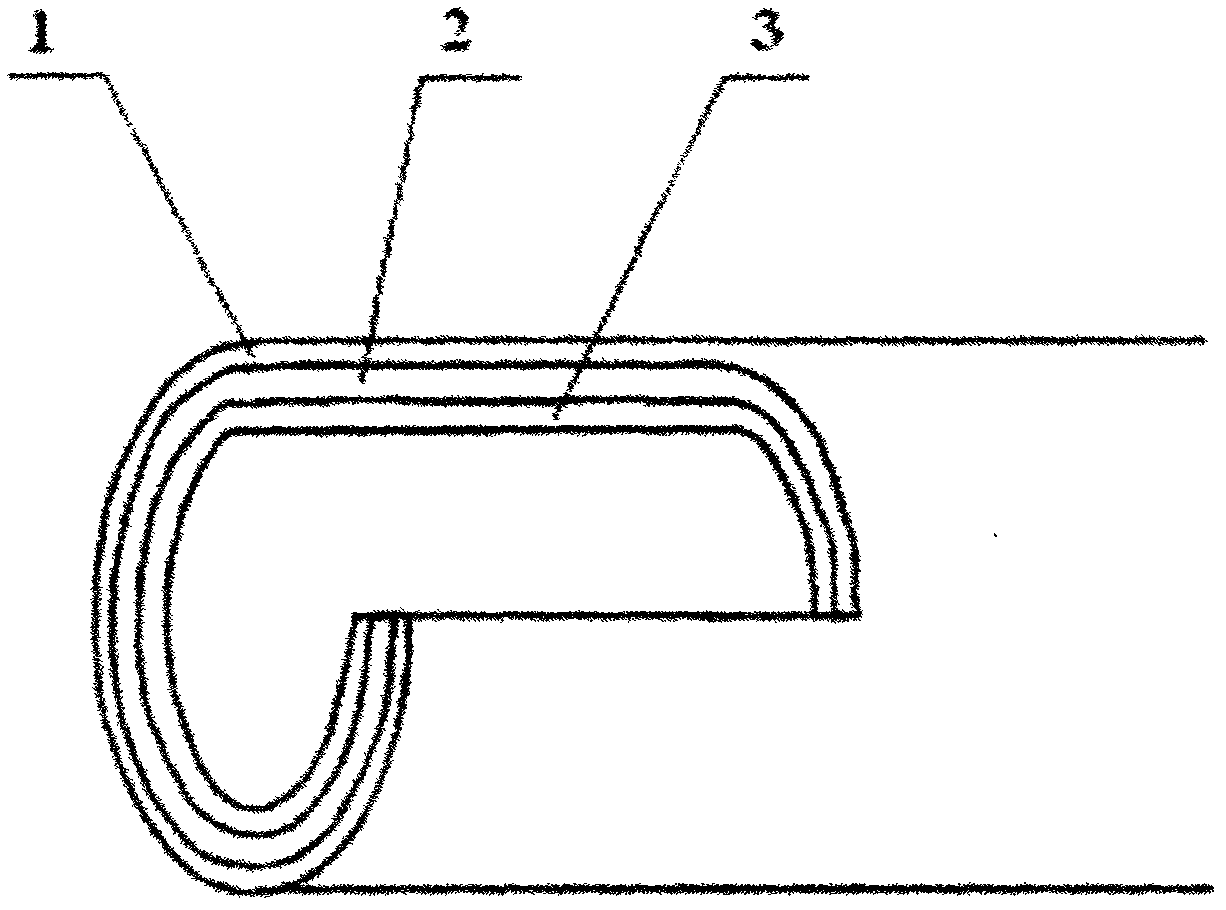

[0036] An environment-friendly oxygen barrier and antibacterial PP-R pipe, PP-R outer layer 1, PP-R oxygen barrier middle layer 2 and PP-R antibacterial inner layer 3, the formula of PP-R outer layer 1 is:

[0037] 50kg of special material for PP-R hot water pipe (model RP2400), 50kg of special material for PP-R cold water pipe (model 4220), 2kg of color masterbatch for pipe;

[0038] The formula of PP-R oxygen barrier middle layer 2 is: 50kg of PP-R hot water pipe special material (model RP2400), 2kg of high-performance oxygen barrier, and 2kg of color masterbatch;

[0039] The formula of PP-R antibacterial inner layer 3 is: 50kg of PP-R special material for hot water pipes (model RP2400), 2kg of inorganic antibacterial masterbatch (among them, 0.1kg of silver nitrate, 2kg of PP-R resin), and 2kg of color masterbatch.

[0040] The preparation process is as follows: choose a three-layer composite mold, connect with three plastic extruders, and preheat; start the feeding equipm...

Embodiment 2

[0042] An environment-friendly oxygen barrier and antibacterial PP-R pipe, PP-R outer layer 1, PP-R oxygen barrier middle layer 2 and PP-R antibacterial inner layer 3, the formula of PP-R outer layer 1 is:

[0043] PP-R hot water pipe special material (model RP2400) 100kg, PP-R cold water pipe special material (model 4220) 100kg, pipe special color masterbatch 5kg;

[0044] The formula of the PP-R oxygen barrier middle layer 2 is: PP-R special material for hot water pipes (model RP2400) 100kg, high performance oxygen barrier 5kg, color masterbatch 5kg;

[0045] The formula of PP-R antibacterial inner layer 3 is: 100kg of PP-R special material for hot water pipes (model 400), 5kg of inorganic antibacterial masterbatch (among them, 0.25kg of silver nitrate, 5kg of PP-R resin), and 5kg of color masterbatch.

[0046] The preparation process is the same as in Example 1.

[0047] The prepared antibacterial PP-R tube is detected with reference to QB / T 2591-2003, GB / T18742.2-2002 det...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com