Gas-barrier packaging material

A packaging material and gas-barrier technology, applied in the field of gas-barrier packaging materials, can solve the problems of reduced gas-barrier properties such as oxygen and deterioration of resistance, and achieve excellent productivity and excellent deterioration resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

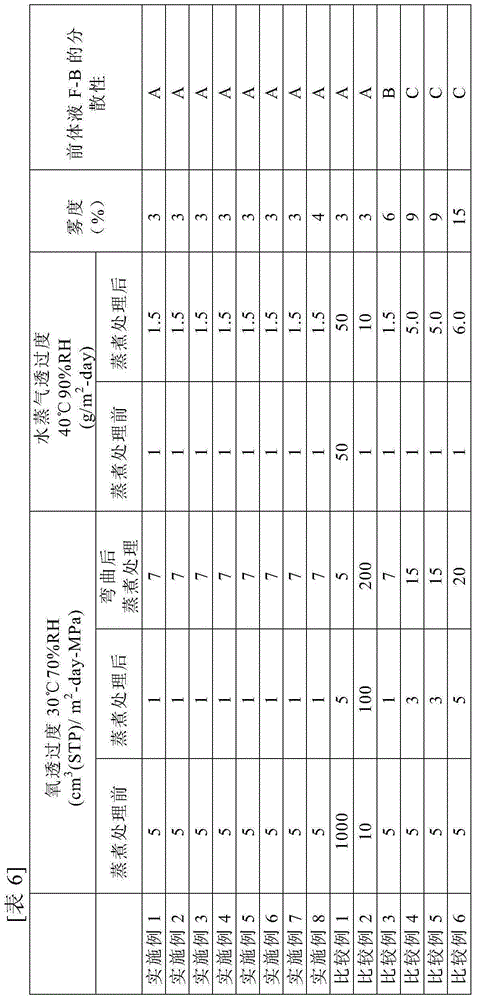

Examples

no. 1 Embodiment approach 》

[0030] The gas barrier packaging material according to the first embodiment of the present invention has a support, an adhesive layer laminated on the support, a first barrier layer laminated on the adhesive layer, and a first barrier layer laminated on the first adhesive layer. A second barrier layer on the barrier layer, and a protective layer laminated on the second barrier layer, the protective layer is formed from a coating solution containing a polyvalent metal compound, a polyester resin, and a dispersant, the dispersant It is a sodium salt of a polycarboxylic acid-based resin, wherein, relative to 100% by weight of the protective layer, the polyvalent metal compound is contained in an amount of 40% to 90% by weight, and after the second barrier layer is separated and When the infrared absorption spectrum of the separated second barrier layer is measured by the transmission method, 1490cm -1 to 1659cm -1 The maximum peak height α within the range is 1660cm -1 to 1750c...

no. 2 Embodiment approach 》

[0144] The gas-barrier packaging material according to the second embodiment of the present invention is obtained by subjecting the gas-barrier packaging material according to the above-mentioned first embodiment to at least one treatment selected from the group consisting of retort treatment, boiling treatment, and humidity-conditioning treatment. A gas-barrier packaging material, wherein, when the second barrier layer is separated and the infrared absorption spectrum of the separated second barrier layer is measured by the transmission method, 1490 cm -1 to 1659cm -1 The maximum peak height α within the range is 1660cm -1 to 1750cm -1 The ratio α / β of the maximum peak height β within the range is 1 or more.

[0145] [Steaming treatment, boiling treatment and humidity conditioning treatment]

[0146] Regarding the gas barrier packaging material of the present embodiment, the above gas barrier packaging material is subjected to at least one treatment selected from the group...

Embodiment 1

[0226] A stretched PET film was used as a base material, and the coating solution A was applied onto the base material using a bar coater so that the thickness after drying was 0.2 μm, and dried to obtain a [substrate / adhesive layer]. As the stretched PET film, a polyethylene terephthalate film Lumilar P60 (12 μm) manufactured by Toray was used.

[0227] On the adhesive layer in the [substrate / adhesive layer], metal aluminum is evaporated using an electron beam heating vacuum deposition device, and oxygen is introduced into the vaporized aluminum so that aluminum oxide is deposited on the adhesive layer, thereby An inorganic deposition layer with a thickness of 20 nm was formed to obtain [substrate / adhesive layer / first barrier layer].

[0228]On the first barrier layer of [substrate / adhesive layer / first barrier layer] obtained in this way, use a bar coater so that the thickness of the above-mentioned coating solution E after drying becomes 0.3 μm, and the drying of the above-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com