Multi-layer composite pipe material and preparation method thereof

A multi-layer composite and layer-composite technology, which is applied in the direction of pipes, rigid pipes, and pipeline protection. problems, to achieve the effects of good mechanical strength and toughness, outstanding oxygen barrier properties, and tight interlayer bonding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

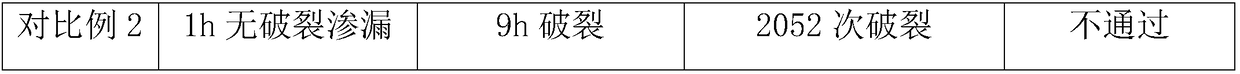

Examples

preparation example Construction

[0032] Adopt the preparation method of a kind of multi-layer composite pipe material as claimed in claim 1, comprise the steps:

[0033] (1) Add different materials to the three extruders that are extruded to form the inner layer, the middle layer and the outer layer, wherein fluoroolefin polymer pellets are added to the extruder used to form the inner layer to form the outer layer Add random polyolefin pellets to the extruder for the middle layer, and add alloy pellets to the extruder for forming the middle layer. After the alloy pellets are mixed with a compatibilizer, fluoroolefin polymer and random polyolefin, the obtained by extrusion granulation;

[0034](2) Under certain extrusion process conditions, use three extruders to extrude the inner layer, middle layer and outer layer respectively. The barrels of the three extruders are divided into 6 heating sections for the inner layer The heating temperature of each section of the barrel of the extruder is: the heating tempe...

Embodiment 1

[0038] The outer layer material uses random polypropylene, and the usage amount is 100 parts by weight; the middle layer material uses an alloy of polyvinylidene fluoride and random polypropylene, and the usage amount is 20 parts by weight, including 45% by weight. Polyvinylidene fluoride, 10% compatibilizer material and 45% random polypropylene; the inner layer material is vinylidene fluoride homopolymer, and the usage amount is 20 parts by weight. Composite pipes are obtained through three-layer co-extrusion once.

Embodiment 2

[0040] The material of the outer layer is atactic polypropylene, and the amount used is 100 parts by weight; the material of the middle layer is an alloy of polyvinylidene fluoride and random polypropylene, and the amount used is 40 parts by weight, including a mass fraction of 40% polypropylene. Vinylidene fluoride, 20% compatibilizer material and 40% random polypropylene; the inner layer material is vinylidene fluoride homopolymer, and the usage amount is 40 parts by weight. Composite pipes are obtained through three-layer co-extrusion once.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com