High-temperature-resistant ablation-resistant composite coating and preparation method thereof

A composite coating and anti-ablation technology, which is applied in coating, metal material coating process, fusion spraying, etc., can solve the problems of fast volatilization speed and poor thermodynamic stability, and achieve low porosity, low cost, and good The effect of oxygen barrier performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

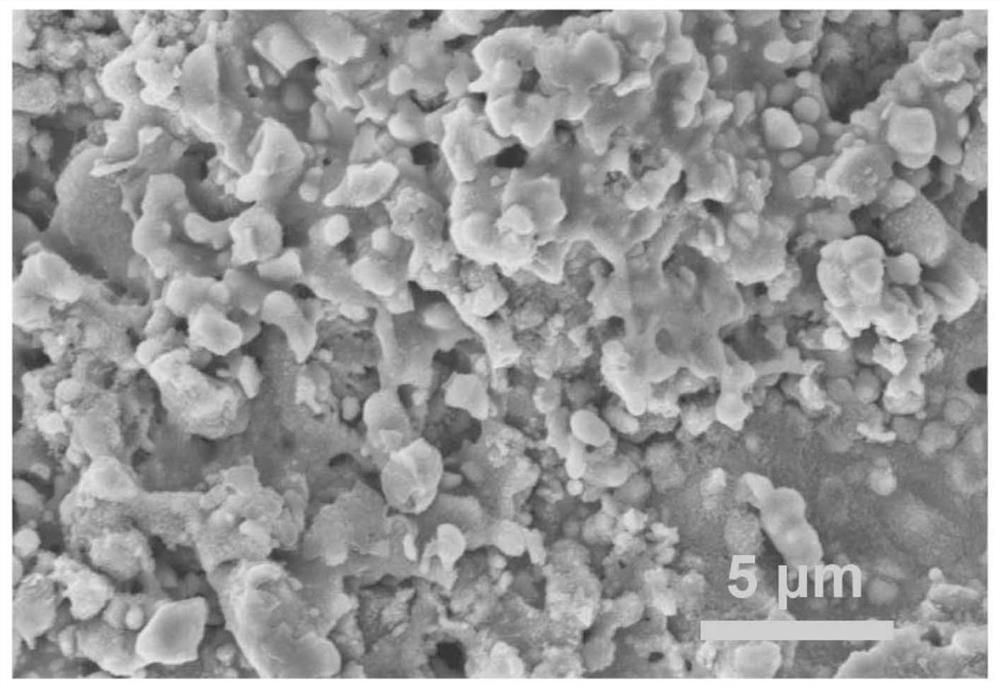

[0047] Preparation of raw material powder. The main phase ZrB 2 Powder, second phase MoSi 2 powder, and the third phase Yb 2 o 3 The powders are mixed according to a certain ratio to obtain raw material powders. Among them, the second phase MoSi 2 The content of the powder accounts for 5-30vol.%, preferably 20-30%, of the total volume of the raw material powder. Yb 2 o 3 The content accounts for 5-20 mol.%, preferably 5-15 mol.% of the total moles of raw material powder. Specifically, the main phase ZrB 2 Powder, second phase MoSi 2 Powder and third phase Yb 2 o 3The powder is mixed according to a certain ratio to obtain ZrB 2 -MoSi 2 -Yb 2 o 3 Composite powder. The powder mixing method can adopt the planetary ball milling method. In the case of a planetary ball mill, the mixing process includes, for example: using absolute ethanol or deionized water as a medium, using ZrO 2 Mixing is carried out, and the mixing time can be 2-10 hours. The uniformly mixed pow...

Embodiment 1

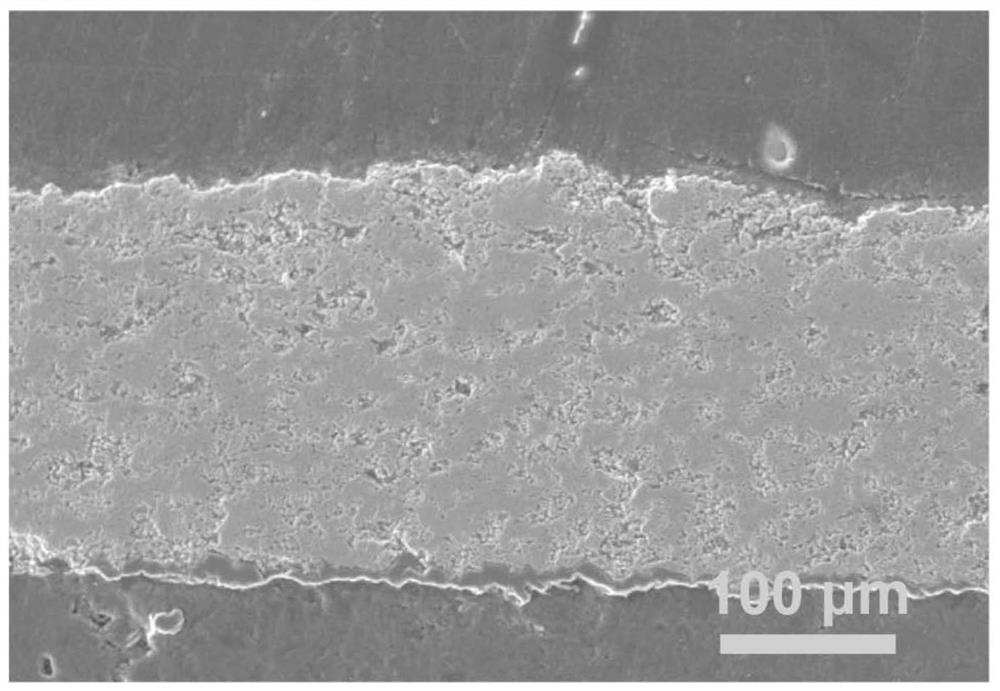

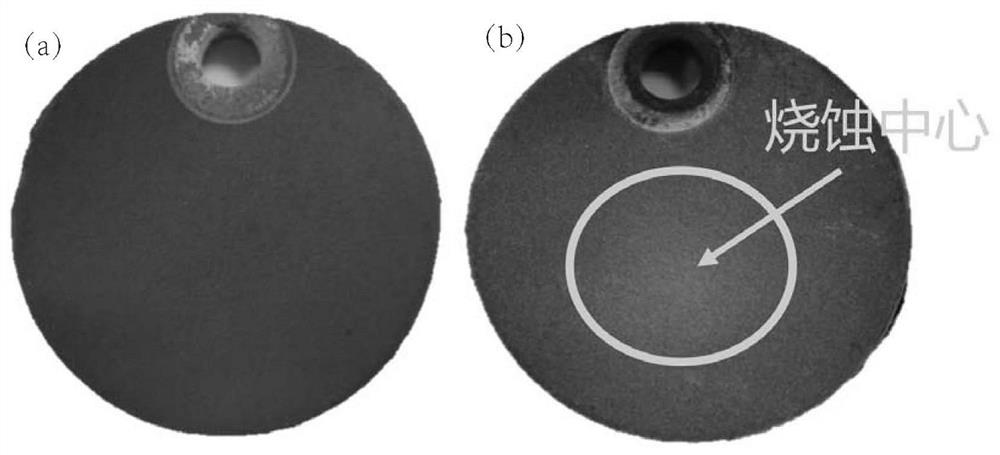

[0054] A kind of high temperature and anti-ablation composite coating, made of ZrB 2 -MoSi 2 -Yb 2 o 3 composition. Among them, ZrB 2 The particle size of the powder ranges from 5 to 90 μm, and the purity is 99.0wt.%. MoSi 2 The particle size of the powder ranges from 5 to 90 μm, and the purity is 99.0wt.%; Yb 2 o 3 The particle size range of the powder is 5-90 μm, and the purity is 99.0wt.%. Prepare above-mentioned composite coating and carry out according to the following steps:

[0055] (1) With the C / C composite material covered with SiC transition layer as the substrate, the surface of the substrate is subjected to sandblasting roughening treatment, the blasting pressure is 0.2MPa, and absolute ethanol is used as the medium, and ultrasonic cleaning is performed twice, each time 10 minutes, dry in an oven at 100°C for 1 to 2 hours, and set aside;

[0056] (2)ZrB 2 、MoSi 2 and Yb 2 o 3 The powders are mixed according to a certain ratio, in which the second phas...

Embodiment 2

[0068] A kind of high temperature and anti-ablation composite coating, made of ZrB 2 -MoSi 2 -Yb 2 o 3 composition. Among them, ZrB 2 The particle size of the powder ranges from 5 to 90 μm, and the purity is 99.0wt.%. MoSi 2 The particle size of the powder ranges from 5 to 90 μm, and the purity is 99.0wt.%; Yb 2 o 3 The particle size range of the powder is 5-90 μm, and the purity is 99.0wt.%. Prepare above-mentioned composite coating and carry out according to the following steps:

[0069] (1) With the C / C composite material covered with SiC transition layer as the substrate, the surface of the substrate is subjected to sandblasting roughening treatment, the blasting pressure is 0.2MPa, and absolute ethanol is used as the medium, and ultrasonic cleaning is performed twice, each time 10 minutes, dry in an oven at 100°C for 1 to 2 hours, and set aside;

[0070] (2)ZrB 2 、MoSi 2 and Yb 2 o 3 The powders are mixed according to a certain ratio, in which the second phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com