Edible antibacterial food packaging film

A technology of food packaging film and food properties, applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problem of poor material performance that cannot meet the requirements of food packaging mechanical properties, moisture resistance, oxygen resistance, oil resistance and antibacterial properties , weak interaction and other problems, to achieve good application prospects, good oil resistance, and prevent corruption and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

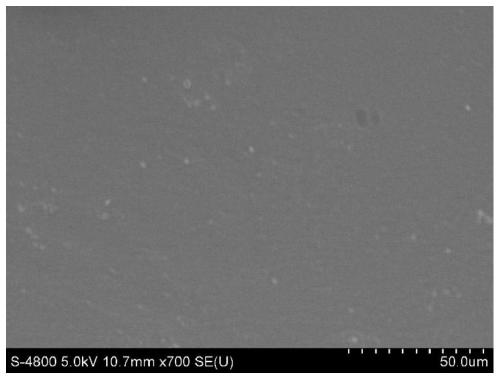

[0015] The main components of an edible antibacterial food packaging film are: cellulose sulfate or its salt, soybean protein isolate, natural antibacterial agent, glycerin, cellulose sulfate or its salt, soybean protein isolate, natural antibacterial agent, The weight ratio of glycerin is 10-70:1-70:1-10:1-5.

[0016] The preparation method of edible antibacterial food packaging film comprises the following steps:

[0017] (1) Dissolve 2 g of cellulose sulfate in 100 mL of deionized water to form a 2% (W / V) cellulose sulfate solution, and let stand at 4° C. for 12 hours to obtain solution 1;

[0018] (2) Dissolve 2g of soybean protein isolate in 100mL of 1% (V / V) acetic acid aqueous solution, heat to 50°C to form a 2% (W / V) isolate of soybean protein solution, and let stand at 4°C for 12h to obtain solution 2 ;

[0019] (4) 1 g of eugenol was dissolved in 100 mL of ethanol to form a 1% (W / V) eugenol solution, which was allowed to stand at 4° C. for 12 hours to obtain soluti...

Embodiment 2

[0029] A preparation method of sodium cellulose sulfate / soy protein isolate / eugenol edible antibacterial food packaging film, said preparation method comprising the steps of:

[0030] (1) Dissolve 2 g of cellulose sodium sulfate in 100 mL of deionized water to form a 2% (W / V) cellulose sodium sulfate solution, and let stand at 4°C for 12 hours to obtain solution 1;

[0031] (2) Dissolve 2g of soybean protein isolate in 100mL of 1% (V / V) acetic acid aqueous solution, heat to 50°C to form a 2% (W / V) isolate of soybean protein solution, and let stand at 4°C for 12h to obtain solution 2 ;

[0032] (4) 1 g of eugenol was dissolved in 100 mL of ethanol to form a 1% (W / V) eugenol solution, which was allowed to stand at 4° C. for 12 hours to obtain solution 3;

[0033] (5) Dissolve 1 g of glycerin in 100 mL of deionized water to form a 1% (W / V) glycerin solution, and let stand at 4°C for 12 hours to obtain solution 4;

[0034] (6) Mix solution 1, solution 2, solution 3 and solution ...

Embodiment 3

[0036] A preparation method of cellulose sulfate / soy protein isolate / cinnamaldehyde edible antibacterial food packaging film, said preparation method comprising the steps of:

[0037] (1) Dissolve 2 g of cellulose sulfate in 100 mL of deionized water to form a 2% (W / V) cellulose sulfate solution, and let stand at 4° C. for 12 hours to obtain solution 1;

[0038] (2) Dissolve 2g of soybean protein isolate in 100mL of 1% (V / V) acetic acid aqueous solution, heat to 50°C to form a 2% (W / V) isolate of soybean protein solution, and let stand at 4°C for 12h to obtain solution 2 ;

[0039] (4) 1 g of cinnamaldehyde was dissolved in 100 mL of ethanol to form a 1% (W / V) cinnamaldehyde solution, which was allowed to stand at 4° C. for 12 hours to obtain solution 3;

[0040] (5) Dissolve 1 g of glycerin in 100 mL of deionized water to form a 1% (W / V) glycerin solution, and let stand at 4°C for 12 hours to obtain solution 4;

[0041] (6) Mix solution 1, solution 2, solution 3, and soluti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com