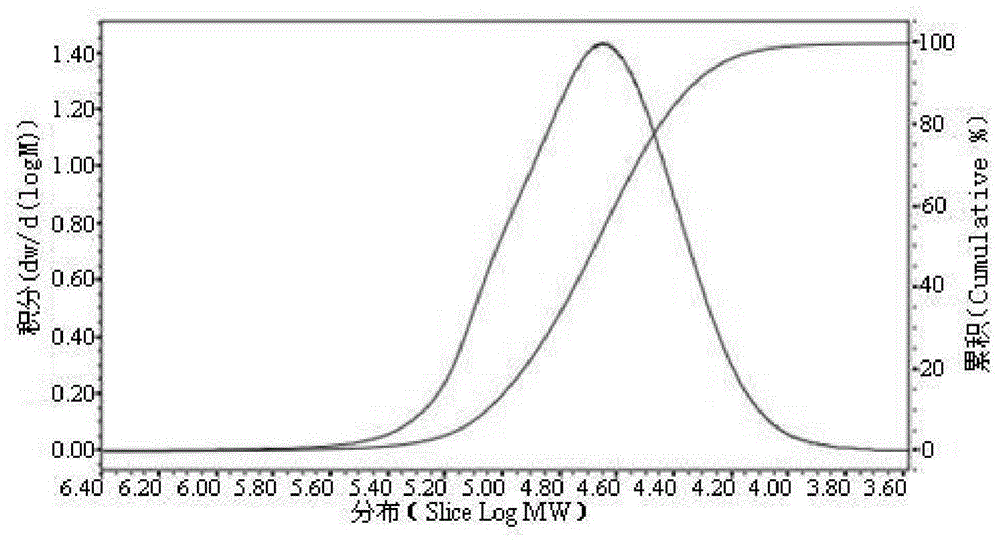

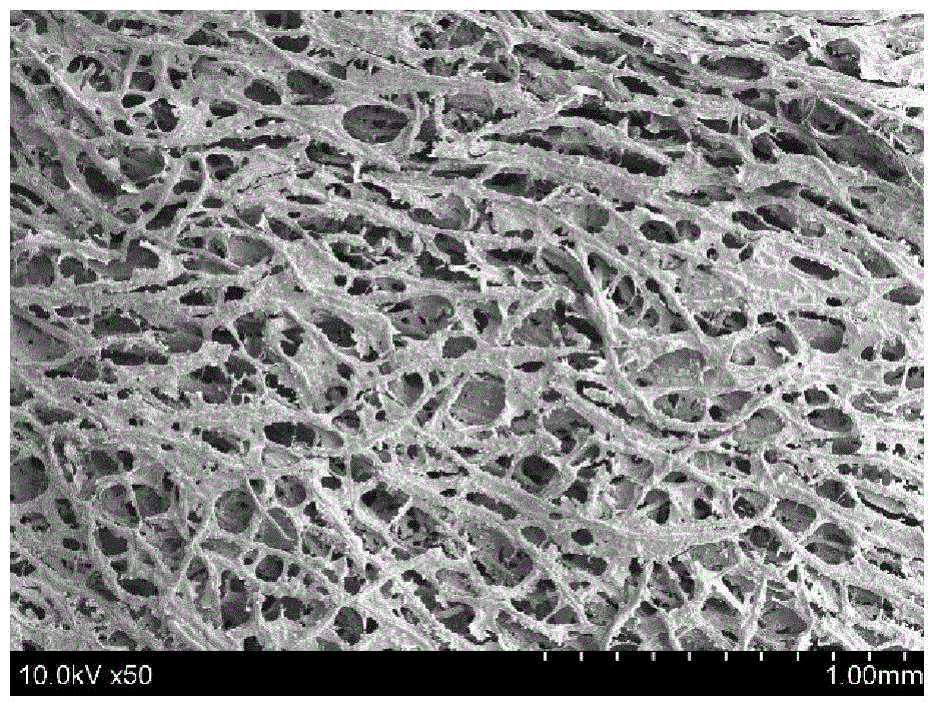

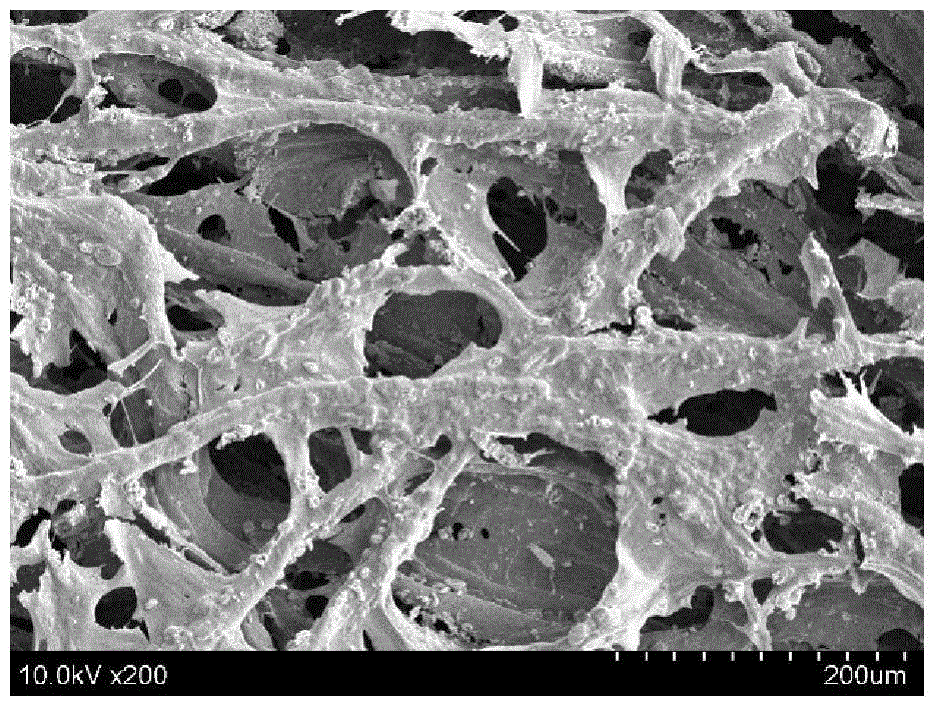

Cellulose sulfate hydrogel and preparation method thereof

A cellulose sulfate and hydrogel technology, applied in the field of gel materials, can solve problems such as unreported research on cellulose ester hydrogels, and achieve increased strength, increased hydrogel strength, and a three-dimensional network. The effect of dense structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] A kind of preparation method of cellulose sulfate hydrogel of the present embodiment, concrete operation steps are as follows:

[0034] Dimethylformamide (DMF) was used Molecular sieves are dried to remove moisture, placed in a four-necked flask with a condenser tube and a stirring device in an ice-water mixing bath, and chlorosulfonic acid is slowly added dropwise to dimethylformamide at a rate of 10 drops / min to mix the two For the reaction, dry nitrogen gas was introduced during the reaction, and magnetic stirring was performed at a stirring speed of 100 r / min, and the resulting solution was transferred to an Erlenmeyer flask for later use.

[0035] Put the wood pulp cellulose in a three-necked flask, and slowly add 1 mol / mol AGU (AGU, anhydro glucose unit) chlorosulfonic acid-dimethylformamide complex esterification agent (chlorosulfuric acid) dropwise at 20°C The volume fraction of the acid is 10%). After reacting for 5 hours, the product was washed with 500ml of...

Embodiment 2

[0039] A kind of preparation method of cellulose sulfate hydrogel of the present embodiment, concrete preparation steps are as follows:

[0040] Dimethylformamide (DMF) was used Molecular sieves are dried to remove moisture, placed in a four-necked flask with a condenser tube and a stirring device in an ice-water mixing bath, and chlorosulfonic acid is slowly added dropwise to dimethylformamide at a rate of 10 drops / min to mix the two For the reaction, dry nitrogen gas was introduced during the reaction, and magnetic stirring was performed at a stirring speed of 100 r / min, and the resulting solution was transferred to an Erlenmeyer flask for later use.

[0041] Put the cotton cellulose in a three-necked flask, slowly add 0.8mol / mol AGU (AGU, anhydroglucose unit) chlorosulfonic acid-dimethylformamide complex esterification agent (chlorosulfuric acid) dropwise at 15°C The volume fraction of the acid is 12%). After reacting for 3 hours, the product was washed with 500ml of absolu...

Embodiment 3

[0044] A kind of preparation method of cellulose sulfate hydrogel of the present embodiment, concrete preparation steps are as follows:

[0045] Dimethylformamide (DMF) was used Molecular sieves are dried to remove moisture, placed in a four-necked flask with a condenser tube and a stirring device in an ice-water mixing bath, and chlorosulfonic acid is slowly added dropwise to dimethylformamide at a rate of 10 drops / min to mix the two For the reaction, dry nitrogen gas was introduced during the reaction, and magnetic stirring was performed at a stirring speed of 100 r / min, and the resulting solution was transferred to an Erlenmeyer flask for later use.

[0046] Hemp cellulose was placed in a three-necked flask, and 1.2mol / mol AGU (AGU, anhydroglucose unit) chlorosulfonic acid-dimethylformamide complex esterification agent (chlorosulfuric acid) was slowly added dropwise at 10°C. The volume fraction of the acid is 15%). After reacting for 5 hours, the product was washed with a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| percent by volume | aaaaa | aaaaa |

| degree of substitution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com