Simple synthesis process of cellulose sulfate

A sulfate and fiber technology, which is applied in the field of simple and general synthesis of cellulose sulfate, can solve problems such as unsatisfactory esterification effect, easy carbonization, and difficulty in improving the degree of esterification.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

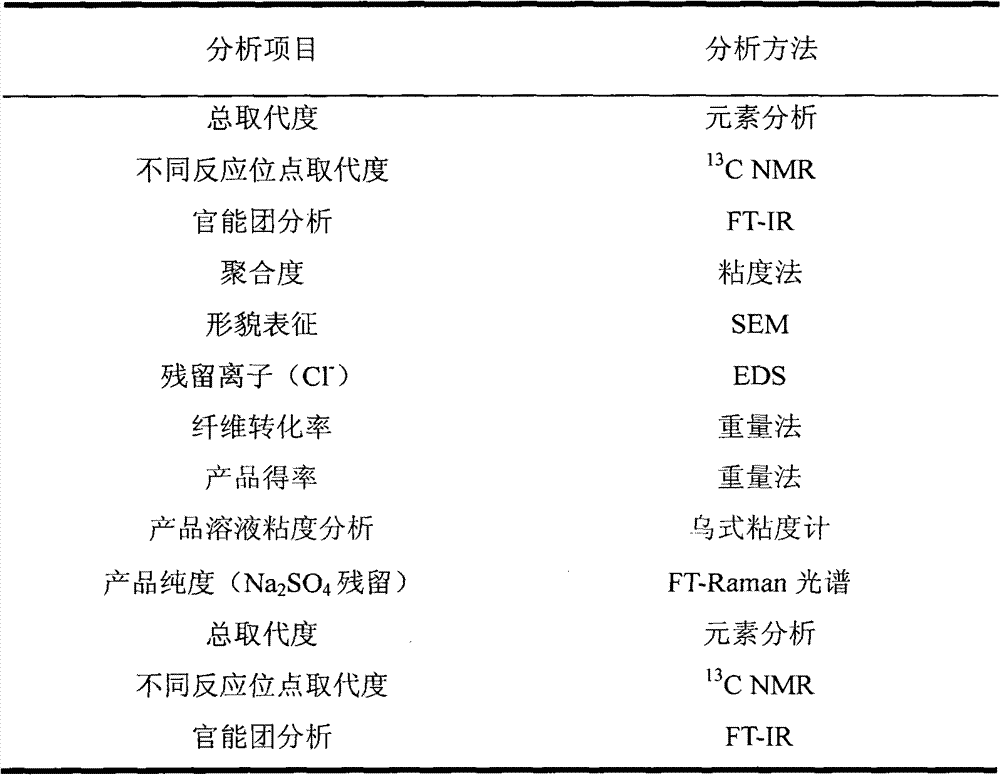

Image

Examples

Embodiment 1

[0036] Solid or gaseous SO 3 , add or pass into cooled 1,2-dichloroethane to form 4mol / L SO 3 / 1,2-dichloroethane solution. Then microcrystalline fiber (MCC) is added in the reactor by the consumption in the table, to SO 3 The effects of solution concentration, dosage, reaction time and reaction temperature on the fiber conversion rate were explored. For the results of related experiments and comparative experiments, see Table 2, Table 3, Table 4, and Table 5.

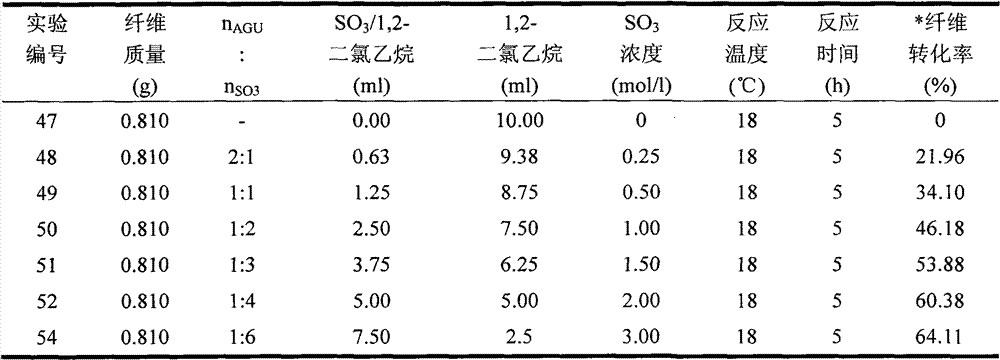

[0037] Table 2: Different SOs 3 Study on the Influence of Concentration on the Conversion Rate of Microcrystalline Fiber

[0038]

[0039] Note: * Fiber conversion rate is the conversion rate of soluble fiber sulfate (the same below)

[0040] no AGU : n SO3 is the number of moles of glucose units of cellulose and SO 3 Ratio of moles (the same below)

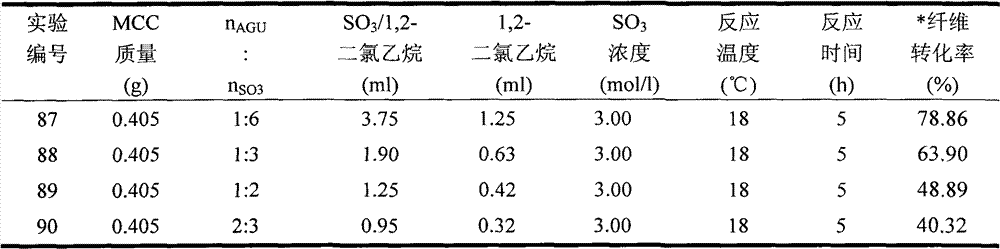

[0041] Table 3 Different SOs 3 Research on the effect of dosage on the conversion rate of microcrystalline fiber

[0042]

[0043] Table 4 Exploration of ...

Embodiment 2

[0049] Solid or gaseous SO 3 , add or pass into cooled dichloromethane to form 3mol / L SO 3 / dichloroethane solution. Using microcrystalline fiber (MCC) as a raw material, the reaction was carried out according to the experimental conditions in Table 6, and the results of related experiments and comparative experiments are shown in Table 6.

[0050] Table VI SO 3 / CH 2 CI 2 systematic exploration

[0051]

Embodiment 3

[0053] Solid or gaseous SO 3 , add or pass into cooled 1,2-dichloroethane to make 3mol / L SO 3 / dichloroethane solution. Then use natural color paste, short cotton linters, and straw powder as fiber raw materials, and react according to the experimental conditions in Table 7. See Table 7 for the results of related experiments and comparative experiments.

[0054] Table 7 Exploration of the sulfation effect of different fibers

[0055]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com