Tunnel fire-proof and heat-preservation sheet material for alpine region and manufacturing method of tunnel fire-proof and heat-preservation sheet material

A technology for fire protection and heat preservation in high and cold areas, applied in fireproof coatings, chemical instruments and methods, manufacturing tools, etc., can solve the problems of neglecting the performance and effect of tunnel heat preservation, low fire resistance limit, easy to fall off, etc., to improve the surface disorder, The effect of improving bond strength and high bond strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

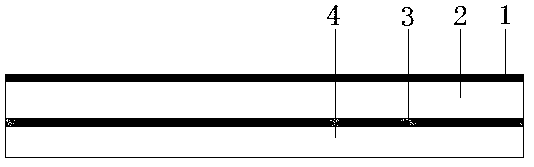

Image

Examples

Embodiment 1

[0038] A fire-proof and heat-preservation board for tunnels used in alpine regions, the specific production method is as follows:

[0039] (1) Clean the wood to remove the surface dust. The cleaned wood is subjected to high temperature and high pressure treatment, put it into a closed tank, keep the relative humidity in the tank not less than 80%, raise the temperature to 120°C, pressurize to 0.4MPa, and treat for 10 minutes ; After drying the wood after high temperature and high pressure treatment until the water content is not more than 10%, the upper surface of the wood is polished with sandpaper to make the surface of the wood get a micro-nano rough structure, and a strip-shaped groove is processed on the lower surface of the wood. The size of the level rough structure is 150 nm, and the size of the groove is 2 mm in width and 2 mm in depth.

[0040] (2) According to the following proportions by weight, 15 parts of water glass, 5 parts of phenolic resin, 1 part of hexameth...

Embodiment 2

[0044] A fire-proof and heat-preservation board for tunnels used in alpine regions, the specific production method is as follows:

[0045](1) Clean the wood to remove the surface dust. The cleaned wood is subjected to high temperature and high pressure treatment, put it into a closed tank, keep the relative humidity in the tank not less than 90%, raise the temperature to 140°C, pressurize to 0.2MPa, and treat for 8 minutes ; After drying the wood after high temperature and high pressure treatment until the water content is not more than 10%, the upper surface of the wood is polished with sandpaper to make the surface of the wood get a micro-nano rough structure, and a strip-shaped groove is processed on the lower surface of the wood. The size of the level rough structure is 250 nm, and the size of the groove is 2 mm in width and 2 mm in depth.

[0046] (2) According to the following proportions by weight, 50 parts of water glass, 15 parts of phenolic resin, 3 parts of hexameth...

Embodiment 3

[0050] A fire-proof and heat-preservation board for tunnels used in alpine regions, the specific production method is as follows:

[0051] (1) Clean the wood to remove the surface dust. The cleaned wood is subjected to high temperature and high pressure treatment, put it into a closed tank, keep the relative humidity in the tank not less than 80%, raise the temperature to 130°C, pressurize to 0.3MPa, and treat for 9 minutes ; After drying the wood after high temperature and high pressure treatment until the water content is not more than 10%, the upper surface of the wood is polished with sandpaper to make the surface of the wood get a micro-nano rough structure, and a strip-shaped groove is processed on the lower surface of the wood. The size of the level rough structure is 200 nm, and the size of the groove is 1.5 mm in width and 2 mm in depth.

[0052] (2) According to the following proportions by weight, 30 parts of water glass, 10 parts of phenolic resin, 2 parts of hexam...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com