Carpet or automobile trim leftover material recycling technology and prepared lyophobic floor tile

A technology for automotive interior trim and leftover materials, which is applied in the field of recycling and preparation of carpet or automotive interior trim scraps, and can solve problems affecting the use effect and service life, low brick adhesion or cohesion, brick breakage or even crushing, etc. , to achieve the effect of reducing the urban heat island effect, low cost, and saving raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

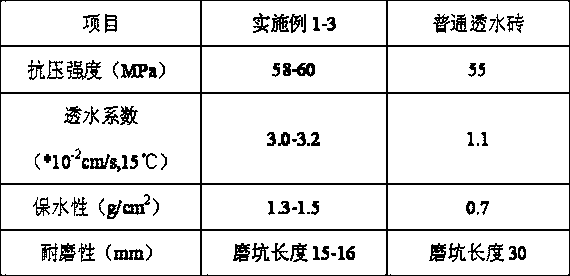

Examples

Embodiment 1

[0035] A kind of carpet or automobile upholstery scrap recycling process, comprises the following steps:

[0036] 1) Broken carpets or car interior scraps; remove other adherents and large impurities from the scraps, and then soak them in a surfactant solution for 4-5 hours to soften them. The concentration of the soaking solution is 5-8% After that, remove the leftover material and clean it with clear water; then add it to a cylinder-type pulverizer, add water and grind it, the quality of the water added is 20-22% of the quality of the leftover material, and the leftover material is broken; then the broken leftover material is mechanically dehydration and drying;

[0037] 2) Heating the scraps of carpet or automobile interior decoration to partially melt to form a plastic body and make solid particles; send the dried and broken scraps into the extruder from the feed port, knead and melt; then knead the molten material High-shear mixing; then pass through two layers of 65-75 ...

Embodiment 2

[0049] A kind of carpet or automobile upholstery scrap recycling process, comprises the following steps:

[0050] 1) Broken carpets or car interior scraps; remove other adherents and large impurities from the scraps, and then soak them in a surfactant solution for 4-5 hours to soften them. The concentration of the soaking solution is 5-8% After that, remove the leftover material and clean it with clear water; then add it to a cylinder-type pulverizer, add water and grind it, the quality of the water added is 20-22% of the quality of the leftover material, and the leftover material is broken; then the broken leftover material is mechanically dehydration and drying;

[0051] 2) Heating the scraps of carpet or automobile interior decoration to partially melt to form a plastic body and make solid particles; send the dried and broken scraps into the extruder from the feed port, knead and melt; then knead the molten material High-shear mixing; then pass through two layers of 65-75 ...

Embodiment 3

[0067] A kind of carpet or automobile upholstery scrap recycling process, comprises the following steps:

[0068] 1) Broken carpets or car interior scraps; remove other adherents and large impurities from the scraps, and then soak them in a surfactant solution for 4-5 hours to soften them. The concentration of the soaking solution is 5-8% After that, remove the leftover material and clean it with clear water; then add it to a cylinder-type pulverizer, add water and grind it, the quality of the water added is 20-22% of the quality of the leftover material, and the leftover material is broken; then the broken leftover material is mechanically dehydration and drying;

[0069] 2) Heating the scraps of carpet or automobile interior decoration to partially melt to form a plastic body and make solid particles; send the dried and broken scraps into the extruder from the feed port, knead and melt; then knead the molten material High-shear mixing; then pass through two layers of 65-75 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com