An underwater artificial fish reef prepared from seawater, sea sand and a non-gold rib material, and having a self-repairing function

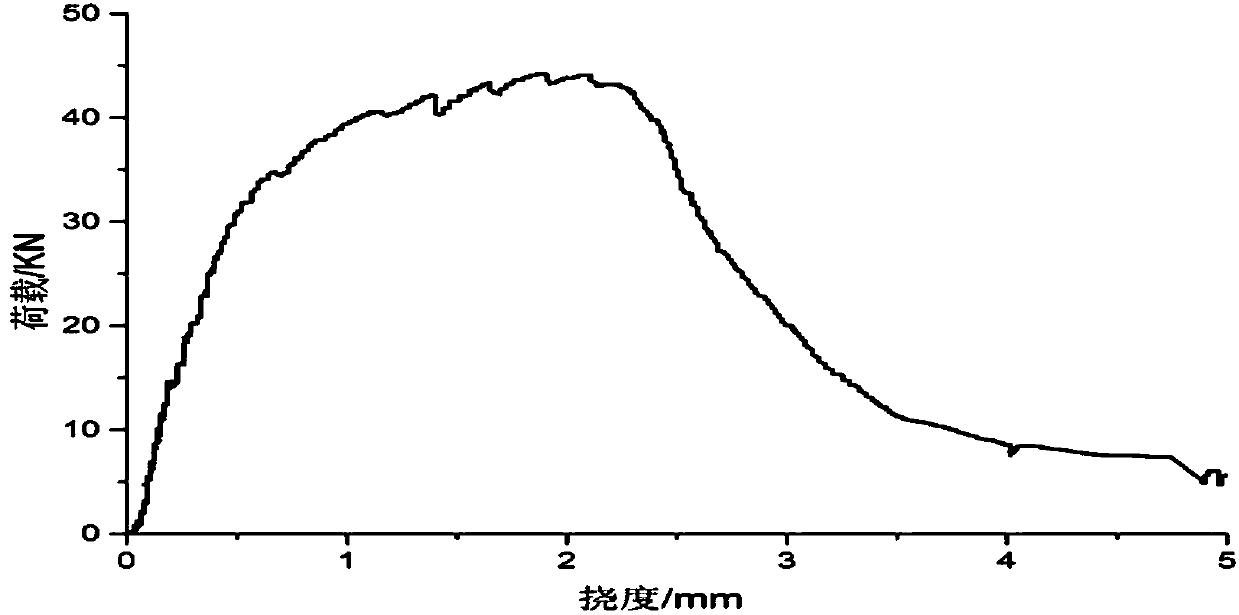

An artificial reef, self-healing technology, applied in fish farming, animal husbandry, applications, etc., can solve the problems affecting the navigation safety of ships, easy to corrode, poor self-repairing ability, etc., to achieve good damage self-repairing function, good resistance Impact performance, the effect of good energy dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] The underwater artificial fish reef with seawater sea sand and non-golden reinforcement material with self-repairing function is made of non-golden reinforcement material and seawater sea sand high-toughness concrete.

[0027] Seawater sea sand high toughness concrete consists of the following components in parts by weight:

[0028] 20 parts of PVA fiber, 750 parts of primary fly ash, 500 parts of P.O 42.5 ordinary Portland cement, 380 parts of sea sand, 300 parts of sea water, and 2.5 parts of polycarboxylate superplasticizer.

[0029] Firstly pour the primary fly ash, ordinary portland cement and sea sand into the mixer, stir until fully mixed, then add seawater and polycarboxylate high-efficiency water reducer and wet mix for 4-6min, when the mixing fluid state reaches the ideal state Then add PVA fiber and continue to stir for 8-10min until the fiber is evenly dispersed.

[0030] The non-gold bars are BFRP fiber composite bars.

[0031] The non-golden bars are pla...

Embodiment 2

[0033] Seawater and sea sand non-gold-reinforced underwater fish reef with self-repairing function is made of non-gold reinforcement and seawater and sea-sand high-toughness concrete.

[0034] Seawater sea sand high toughness concrete consists of the following components in parts by weight:

[0035] 30 parts of PVA fiber, 830 parts of primary fly ash, 551 parts of ordinary Portland cement with P.O 42.5, 415 parts of sea sand, 326 parts of sea water, and 8.3 parts of polycarboxylate superplasticizer.

[0036] The fineness modulus of sea sand is 1.5-3.5.

[0037] Firstly pour the primary fly ash, ordinary portland cement and sea sand into the mixer, stir until fully mixed, then add seawater and polycarboxylate high-efficiency water reducer and wet mix for 4-6min, when the mixing fluid state reaches the ideal state Then add PVA fiber and continue to stir for 8-10min until the fiber is evenly dispersed.

[0038] The non-gold bars are CFRP fiber composite bars.

[0039] The non-...

Embodiment 3

[0041] Seawater and sea sand non-gold-reinforced underwater fish reef with self-repairing function is made of non-gold reinforcement and seawater and sea-sand high-toughness concrete.

[0042] Seawater sea sand high toughness concrete consists of the following components in parts by weight:

[0043] 28 parts of PVA fiber, 820 parts of primary fly ash, 530 parts of ordinary Portland cement with P.O 42.5, 400 parts of sea sand, 310 parts of sea water, and 5.2 parts of polycarboxylate superplasticizer.

[0044] The fineness modulus of sea sand is 1.5-3.5.

[0045] Firstly pour the primary fly ash, ordinary portland cement and sea sand into the mixer, stir until fully mixed, then add seawater and polycarboxylate high-efficiency water reducer and wet mix for 4-6min, when the mixing fluid state reaches the ideal state Then add PVA fiber and continue to stir for 8-10min until the fiber is evenly dispersed.

[0046] Non-gold bars are BFRP, CFRP, and GFRP fiber composite bars.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com