Quick-frozen premixed glutinous rice ball flour and preparation method thereof

A technology for quick-frozen glutinous rice balls and ready-mixed powder, which is applied in the directions of food ingredients as antioxidants, food ingredients as viscosity modifiers, and food ingredients as taste improvers, etc. The problem of different grain thickness, etc., can achieve the effect of smooth and impermeable skin, increased viscosity and gluten, and good quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] A quick-frozen glutinous rice ball premix powder, characterized in that: said quick-frozen glutinous rice ball premix powder comprises the following components in parts by weight:

[0049] 100 parts of raw glutinous rice flour; 50-300 parts of modified glutinous rice flour;

[0050] Accessory materials: 5-50 parts of indica rice flour, 1-20 parts of improver, 10-50 parts of white sugar powder.

[0051] Preferably, the improving agent also includes 1-10 parts of improving agent A, 1-8 parts of improving agent B, 1-8 parts of water-soluble dextran, and 1-10 parts of reduced glutathione.

[0052] Further preferably, the modifier A includes the following components in parts by weight:

[0053] 2-5 parts of amylase A, 3-6 parts of xylanase, 0.5-2 parts of TGase, 0.5-25 parts of vitamin C;

[0054] The improver B includes the following components in parts by weight:

[0055] 3-7 parts of cellulase, 0.5-2 parts of glucose oxidase, 40-70 parts of calcium sodium stearoyl lact...

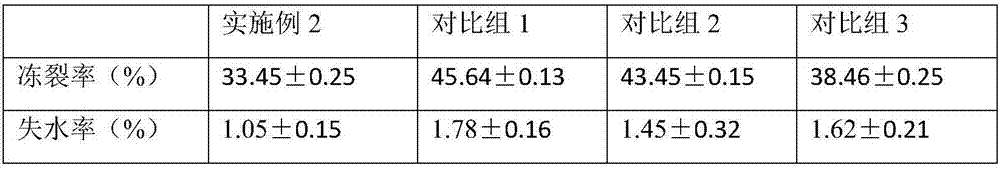

Embodiment 2

[0062] A quick-frozen glutinous rice ball premix powder, characterized in that: said quick-frozen glutinous rice ball premix powder comprises the following components in parts by weight:

[0063] 100 parts of raw glutinous rice flour; 250 parts of modified glutinous rice flour;

[0064] Accessories: 40 parts of indica rice flour, 15 parts of improver, 30 parts of white sugar powder.

[0065] Preferably, the improving agent includes 5 parts of improving agent A, 6 parts of improving agent B, 6 parts of water-soluble dextran, and 8 parts of reduced glutathione.

[0066] Further preferably, the modifier A includes the following components in parts by weight:

[0067] 3 parts of amylase A, 5 parts of xylanase, 1.5 parts of TGase, 15 parts of vitamin C;

[0068] The improver B includes the following components in parts by weight:

[0069] 5 parts of cellulase, 1.5 parts of glucose oxidase, 50 parts of calcium sodium stearoyl lactylate, 80 parts of monoglyceride, 50 parts of defa...

Embodiment 3

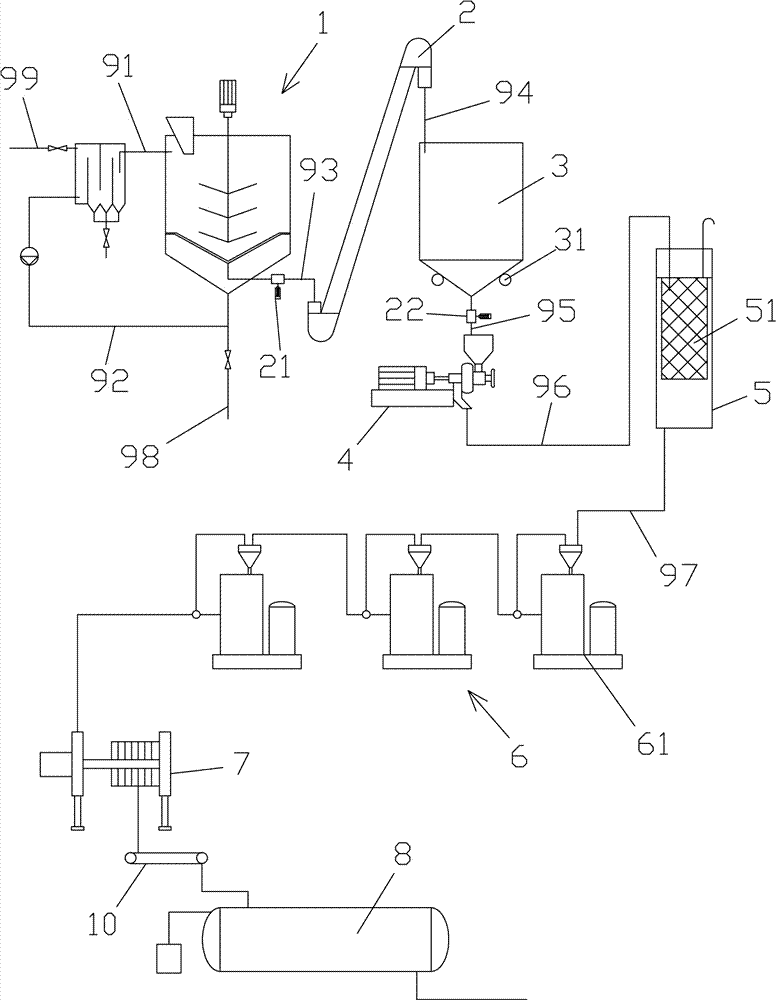

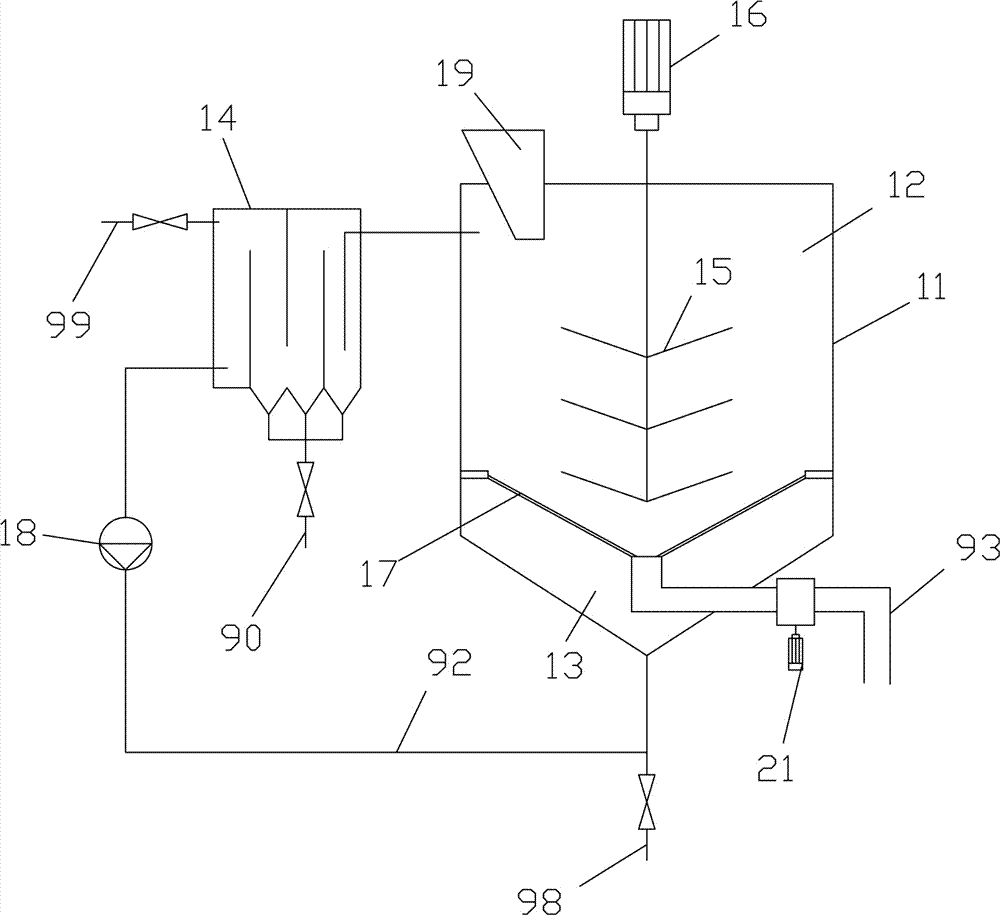

[0096] Such as figure 1 with 2 As shown, the raw glutinous rice flour processing system adopted in embodiment 1-2 includes soaking part 1, bucket elevator 2, storage tank 3, refiner 4, slurry storage tank 3, fine grinding part 6, filter press 7 And low temperature vacuum dryer 8;

[0097]Soaking part 1 comprises tank body 11, filter screen 17, settling tank 14, agitator, feed pipe 19 and discharge pipe 93, filter screen 17 is fixed in the tank body 11, tank body 11 is separated into upper by filter screen 17 Chamber 12 and lower chamber 13, one end of the discharge pipe 93 passes through the outer wall of the tank body 11 and the lower chamber 13 successively and communicates with the middle part of the filter screen 17, and the other end of the discharge pipe 93 communicates with the feed port of the bucket elevator 2, and the feed pipe 19 Installed on the upper end of the tank body 11, the water inlet of the sedimentation tank 14 is connected to the upper end of the upper ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com