Non-toxic marine ship antifouling coating material and preparation method thereof

A technology for antifouling coatings and ships, applied in the field of coatings, can solve problems such as insufficient durability and physical and chemical properties, and achieve the effects of enhancing strength and elastic modulus, increasing cost, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] The present invention also provides a preparation method of the above-mentioned non-toxic marine ship antifouling coating, comprising the following steps:

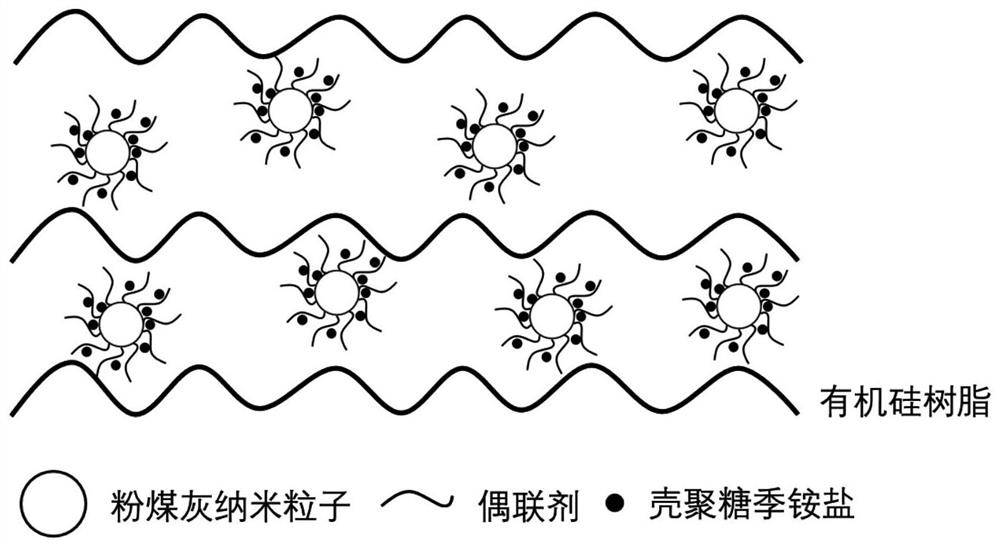

[0047] A) Mix and stir fly ash nanoparticles and coupling agent at high speed, after the temperature rises to 50-70°C, add chitosan quaternary ammonium salt and continue mixing and stirring to obtain fly ash nano particles loaded with chitosan quaternary ammonium salt particle;

[0048] B) adding the fly ash nanoparticles loaded with chitosan quaternary ammonium salt into the silicone resin, and then adding a defoamer, a leveling agent, a catalyst and a curing agent for mixing and stirring to obtain a non-toxic marine antifouling coating.

[0049] In the invention, firstly, the fly ash nano particles and the coupling agent are mixed and stirred at high speed, the stirring speed is 2000-2500 rpm, and the stirring time is 3-5 minutes.

[0050] In the present invention, fly ash nanoparticles are mixed with organosilic...

Embodiment 1~3

[0063] 1. Formula (see Table 1 and Table 2)

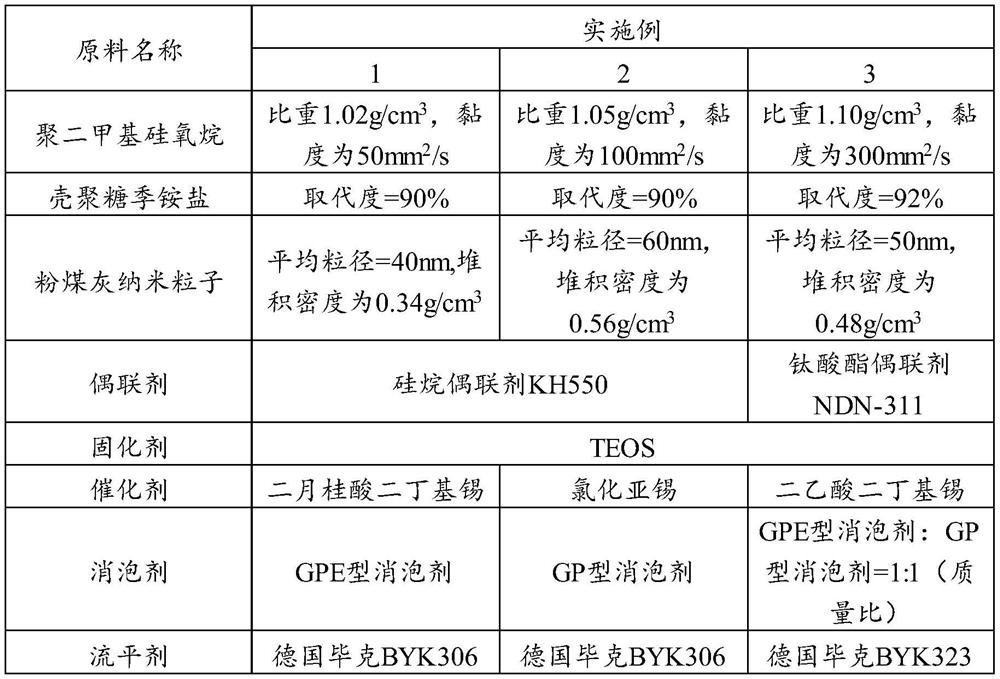

[0064] Types of raw materials in the formula of table 1

[0065]

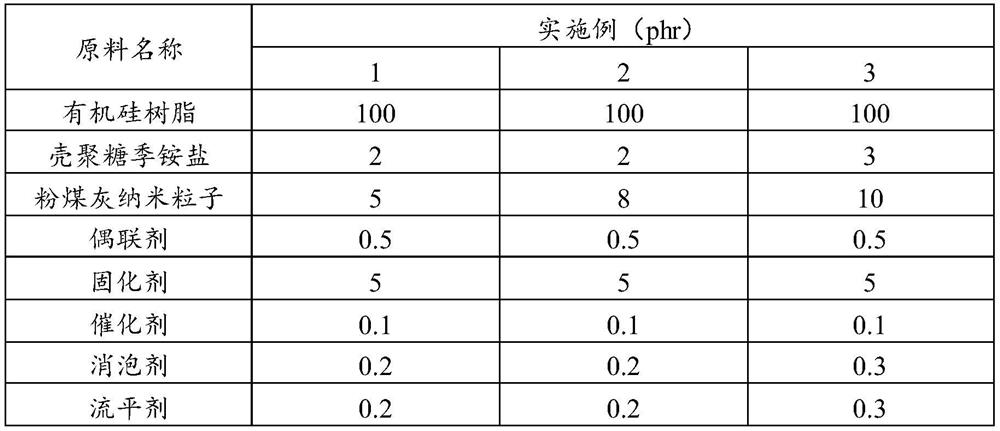

[0066] Raw material consumption in the formula of table 2

[0067]

[0068] 2. Preparation method

[0069] 1. Mix the fly ash nanoparticles and the coupling agent in a high-speed mixer for 3 to 5 minutes (rotation speed is about 2000 to 2500 rpm), and add chitosan quaternary ammonium salt after the temperature rises to 50°C and continue to stir for 30 to 40 minutes , loading quaternary ammonium salts on the surface of fly ash nanoparticles.

[0070] 2. According to the ratio in the formula, add the fly ash nanoparticles loaded with antibacterial agent into the PDMS resin, stir and mix the two at a speed of 50-200rpm for 5 minutes, and then add defoamer, leveling agent, catalyst and curing agent while stirring , continue to stir for 5 minutes, and finally vacuumize for 1 to 2 minutes.

[0071] 3. Quickly take out the above-mentioned mixed colloid, pour film...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com