Heatproof antifouling superhigh voltage insulation material and preparation method thereof

An insulating material, ultra-high voltage technology, applied in insulators, organic insulators, plastic/resin/wax insulators and other directions, can solve the problem of not being able to improve the anti-pollution flashover performance and heat resistance of insulating materials, and improve thermal decomposition. Temperature and anti-fouling ability, good compatibility, the effect of optimizing electric field distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

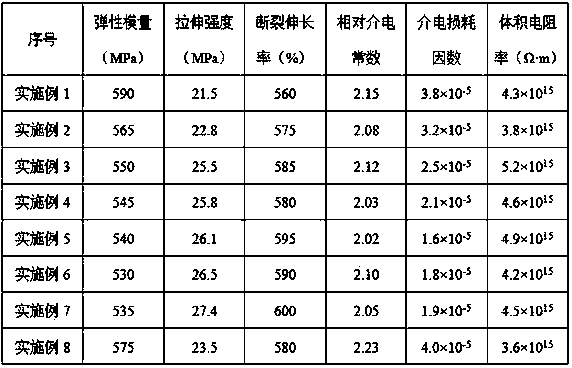

Examples

preparation example Construction

[0038] The present invention also provides a preparation method for the above-mentioned heat-resistant and anti-fouling ultra-high voltage insulating material, comprising the following steps:

[0039] 1) Add 0.1~1 parts by weight of sodium lauryl sulfate to 10~30 parts by weight of distilled water, place in a magnetic stirrer, stir for 15~40 minutes at 20~35°C, and then add 1~5 parts by weight of nano Montmorillonite, stirred in a water bath at 60°C for 3-6 hours, filtered, and dried to obtain surface-modified nano-montmorillonite;

[0040] 2) Add the surface-modified nano-montmorillonite and 100 parts by weight of low-density polyethylene obtained in step 1) to the torque rheometer in sequence, and mix at 140-190°C for 20-25 minutes to obtain low-density polyethylene / Montmorillonite composite material;

[0041] 3) The low-density polyethylene / montmorillonite composite material obtained in step 2), 15-20 parts by weight of fluorosilicone resin, 20-30 parts of polytetrafluor...

Embodiment 1

[0050] A method for preparing a heat-resistant and antifouling ultra-high voltage insulating material, comprising the following steps:

[0051] 1) Add 0.1 part by weight of sodium lauryl sulfate to 10 parts by weight of distilled water, place in a magnetic stirrer, stir for 15 minutes at 20°C, then add 1 part by weight of nano-montmorillonite, and stir in a water bath at 60°C 3h, filter and dry to obtain surface-modified nano-montmorillonite;

[0052] 2) Combine the surface-modified nano-montmorillonite obtained in step 1) with 100 parts by weight and the density is 0.895g / cm 3 , Low-density polyethylene with a melt index of 2.3g / 10min (measured at 190°C / 2.16kg) was sequentially added to the torque rheometer, and mixed at 140°C for 20min to obtain a low-density polyethylene / montmorillonite composite material ;

[0053] 3) The low-density polyethylene / montmorillonite composite material obtained in step 2), 15 parts by weight of fluorosilicone resin, 20 parts by weight of poly...

Embodiment 2

[0057] A method for preparing a heat-resistant and antifouling ultra-high voltage insulating material, comprising the following steps:

[0058] 1) Add 0.3 parts by weight of sodium lauryl sulfate to 15 parts by weight of distilled water, place in a magnetic stirrer, stir at 25°C for 20 minutes, then add 2 parts by weight of nano-montmorillonite, and stir in a water bath at 60°C 3.5h, filter and dry to obtain surface-modified nano-montmorillonite;

[0059] 2) Combine the surface-modified nano-montmorillonite obtained in step 1) with 100 parts by weight of 3 , Low-density polyethylene with a melt index of 3.5g / 10min (measured at 190°C / 2.16kg) was sequentially added to the torque rheometer, and mixed at 150°C for 23min to obtain a low-density polyethylene / montmorillonite composite material ;

[0060] 3) The low-density polyethylene / montmorillonite composite material obtained in step 2), 17 parts by weight of fluorosilicone resin, 22 parts by weight of polytetrafluoroethylene wi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com