A kind of water-based peelable coating and preparation method thereof

A coating and water-based technology, applied in the field of water-based peelable coatings and their preparation, can solve the problems that the tape cannot cover every place and affect the aesthetic effect of the surface.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0031] As an embodiment of the present invention, the film-forming material is a mixture of a polyurethane-based film-forming material and a polyvinyl alcohol-based film-forming material.

[0032] Wherein, as a preferred mode of the present invention, the weight ratio of the polyurethane film-forming material to the polyvinyl alcohol is 1:(0.01-0.1).

[0033] As an embodiment of the present invention, the raw materials for the preparation of the polyurethane-based film-forming material include at least polyol, polyisocyanate and polyoxime.

[0034] As an embodiment of the present invention, the molar ratio of the polyol, polyisocyanate and polyoxime is (0.8-1):(1-1.3):(0.05-0.2).

[0035] As an embodiment of the present invention, the polyol preferably contains an aromatic ring or a condensed ring.

[0036] As a preferred mode of the present invention, the polyol is a polyether polyol.

[0037] As a preferred form of the present invention, the polyether polyol can include, f...

Embodiment approach 1

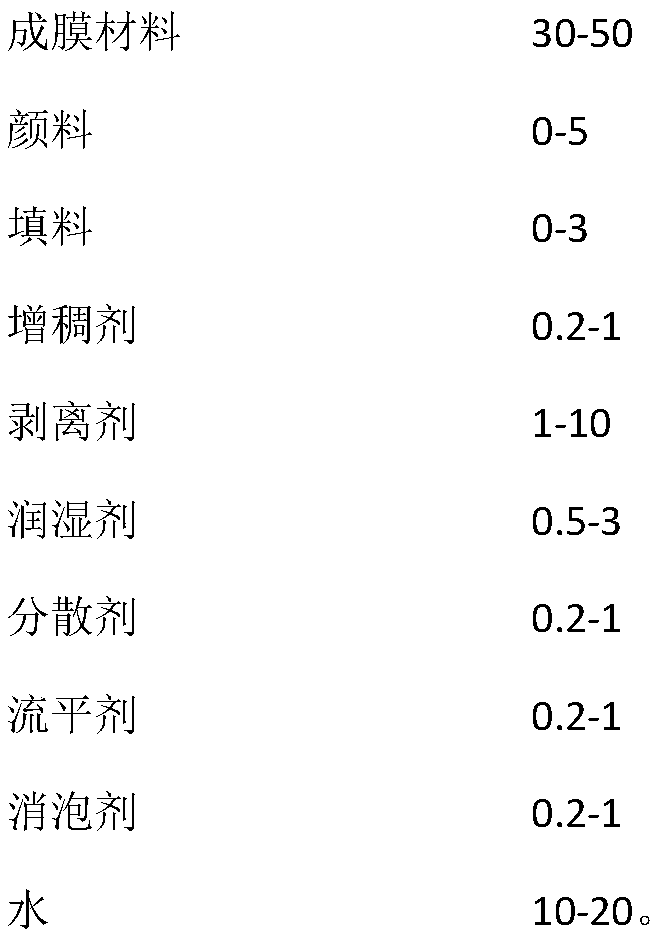

[0112] Embodiment 1: This embodiment provides a kind of water-based peelable coating, by weight, the preparation raw material of described water-based peelable paint comprises:

[0113]

Embodiment approach 2

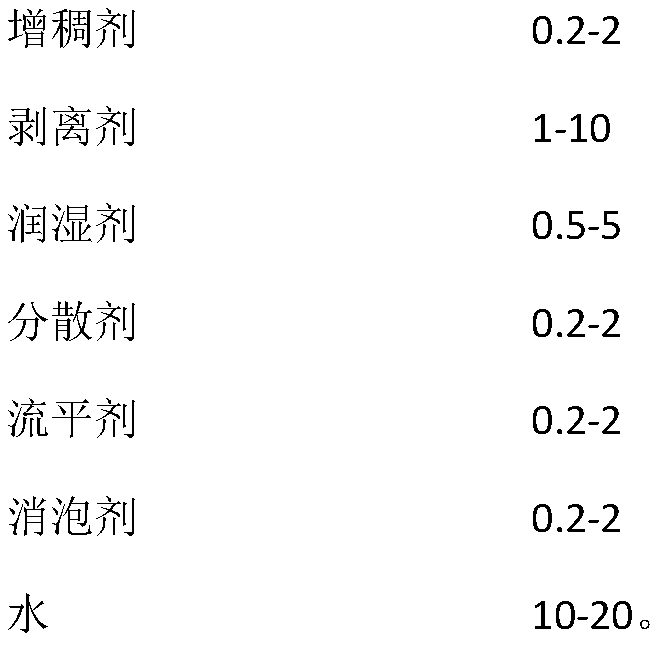

[0114] Embodiment 2. A kind of water-based peelable coating as described in embodiment 1, by weight, the preparation raw material of described water-based peelable paint comprises:

[0115]

[0116]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com