Exhaust gas recirculation (EGR) valve assembly

A technology of exhaust gas recirculation valve and assembly, which is used in exhaust gas recirculation, engine components, machines/engines, etc., can solve the problem of insufficient exhaust gas treatment, substandard exhaust gas emission, and poor valve opening and valve opening accuracy. control issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The following specific descriptions of the present invention are given by the examples, which are only used to further illustrate the present invention, and should not be construed as limiting the protection scope of the present invention.

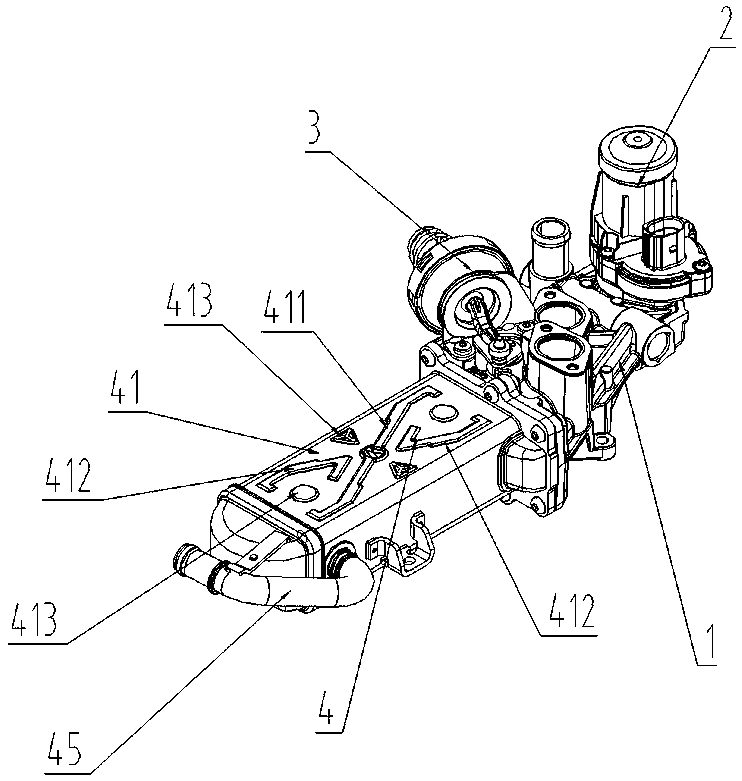

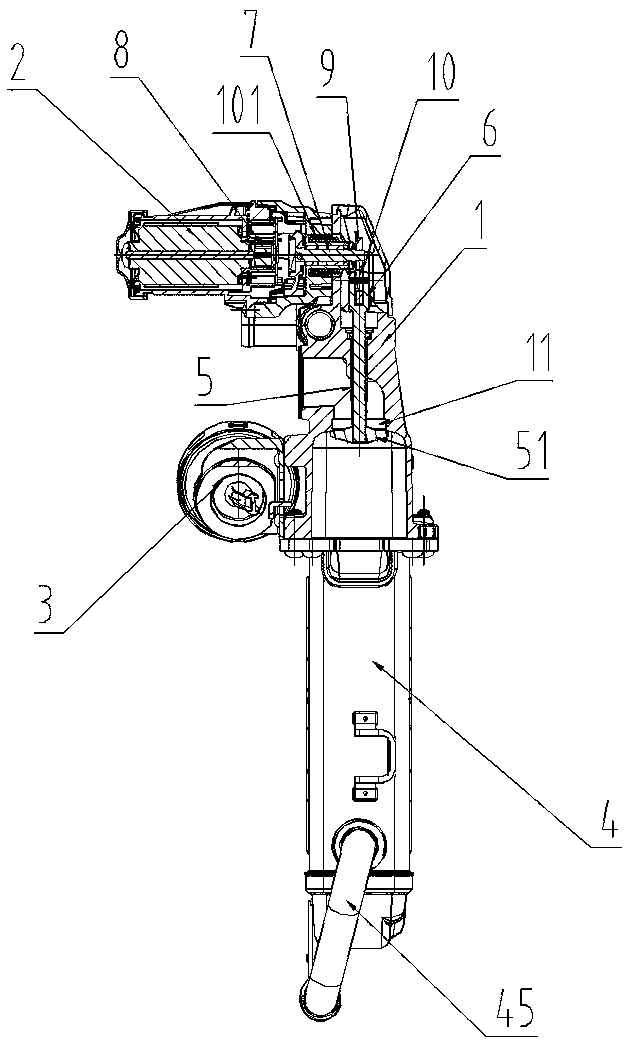

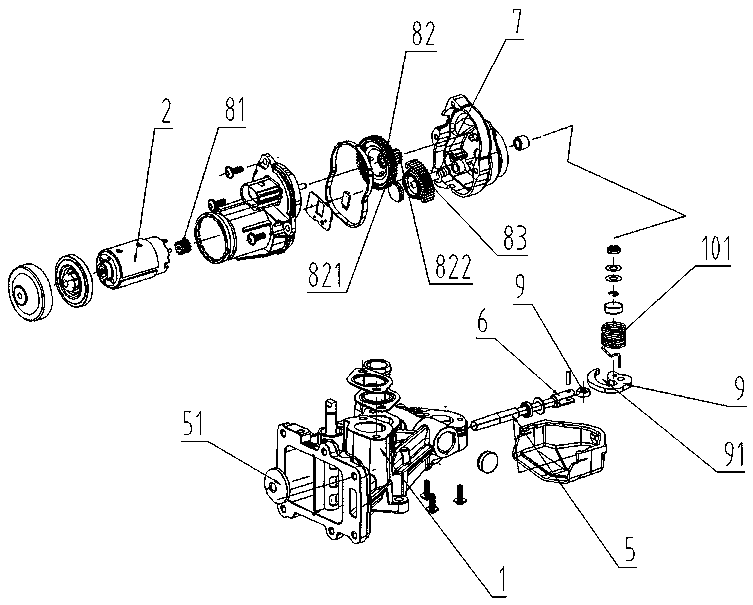

[0018] like figure 1 — Figure 4 As shown, the present invention discloses an EGR exhaust gas recirculation valve assembly, including a valve body 1, a motor 2, a vacuum valve 3 and a cooler 4, the motor 2 and the vacuum valve 3 are installed on the valve body 1, and the valve body 1 The opening is connected with the cooler 4. The valve body 1 is provided with a valve port 11 for exhaust gas to pass through. The valve stem 5 is installed in the valve body 1. The front end of the valve stem 5 is provided with a valve plate 51 that blocks the valve port 11. Inside the valve body 1 The position corresponding to the tail end of the valve stem 5 is provided with an output shaft 7, and the rotating shaft of the motor 2 is connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com