A satellite automatic assembly platform

A technology for assembling platforms and satellites, which is applied in the directions of artificial satellites, workbenches, lifting devices, etc., can solve the problems of single function of satellite assembling platforms, overcome operational instability, realize precise hoisting and docking operations, and improve assembly quality and safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

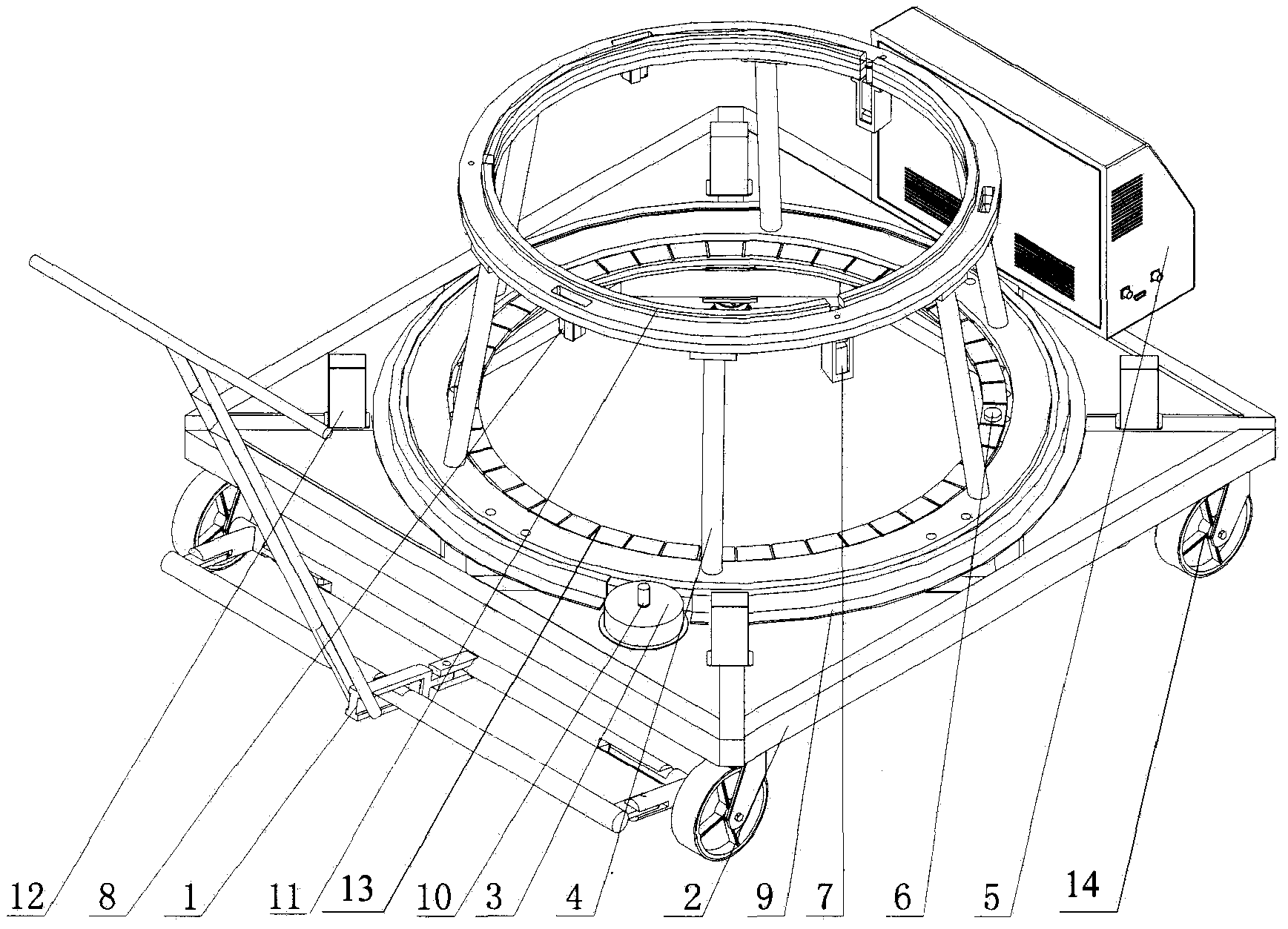

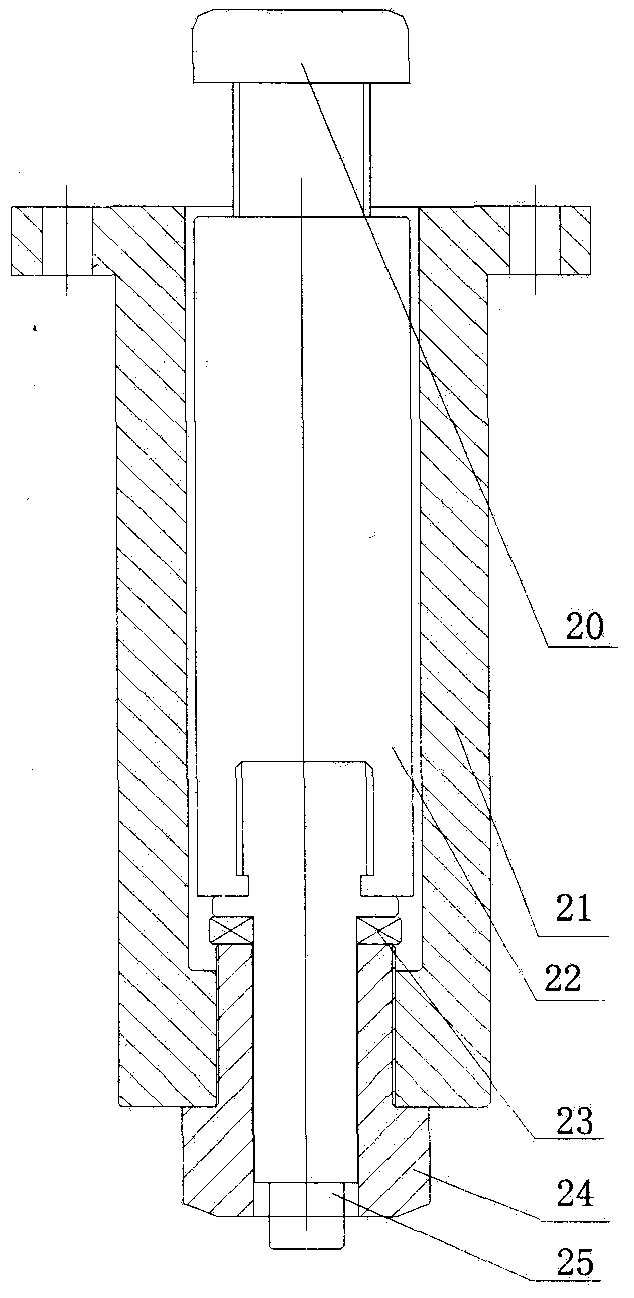

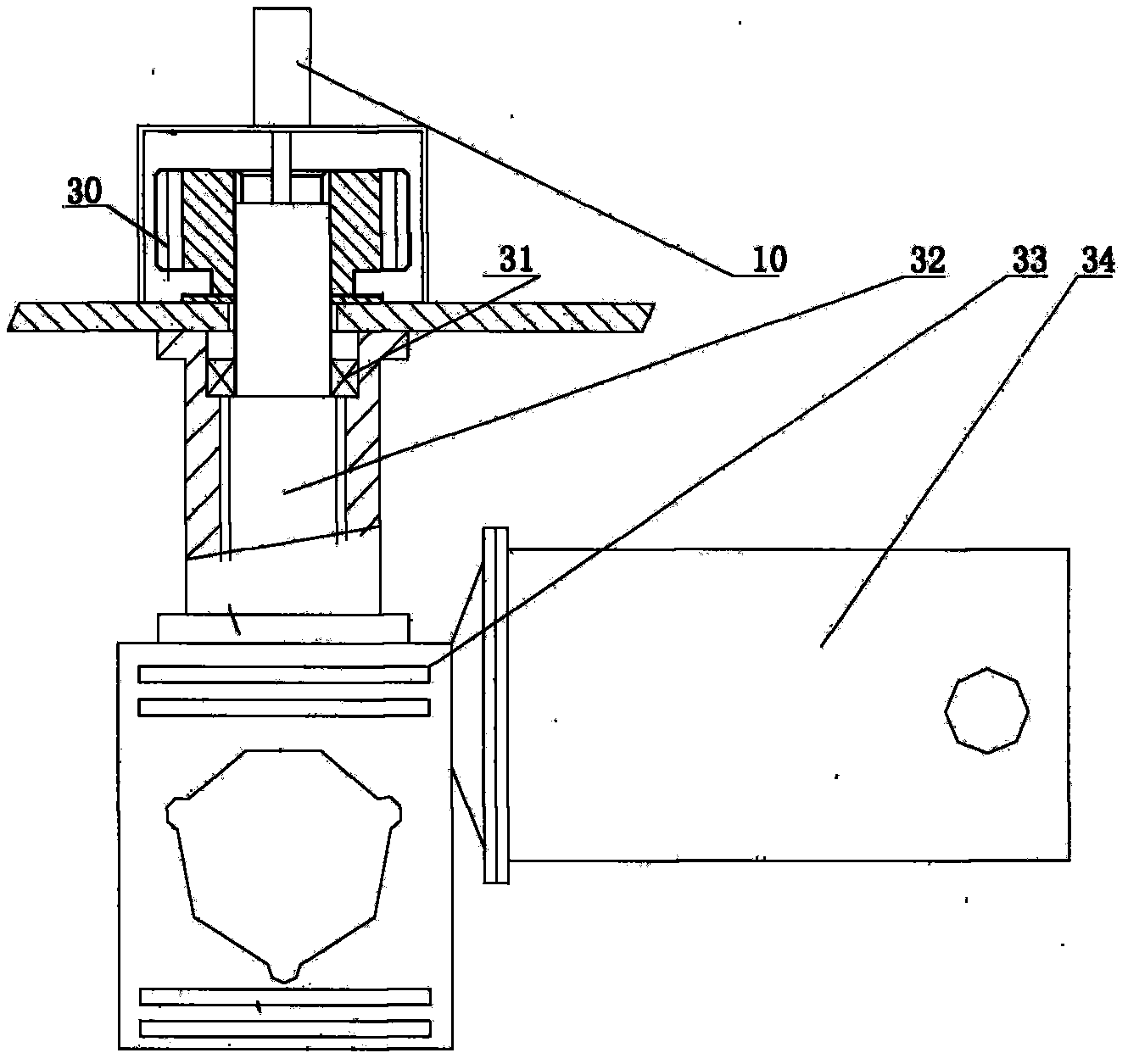

[0025] Such as figure 1 As shown, the assembly platform is composed of three parts: the assembly positioning mechanism, the interface attitude capture device and the control chassis. Assemble the positioning mechanism as the main support structure of the structure body to complete the parking, transportation, and rotation functions of the main body; the interface attitude capture device completes the digital capture of the attitude of the docking surface between the hoisted product and the positioning machine, and can carry out certain adjustments on the hoisted product. The centroid is roughly measured. The electronic control system, computer and corresponding operating components are installed in the control box, and the computer in the electric control box 5 is used to operate the automatic assembly platform, including the measurement of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com