Crankshaft eccentricity tool

An eccentric and tooling technology, applied in the field of technical processing, can solve the problems of high production cost, waste, and affecting the machining accuracy of crankshaft cranks, etc., and achieve the effect of easy transformation, low cost, and convenient and quick disassembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

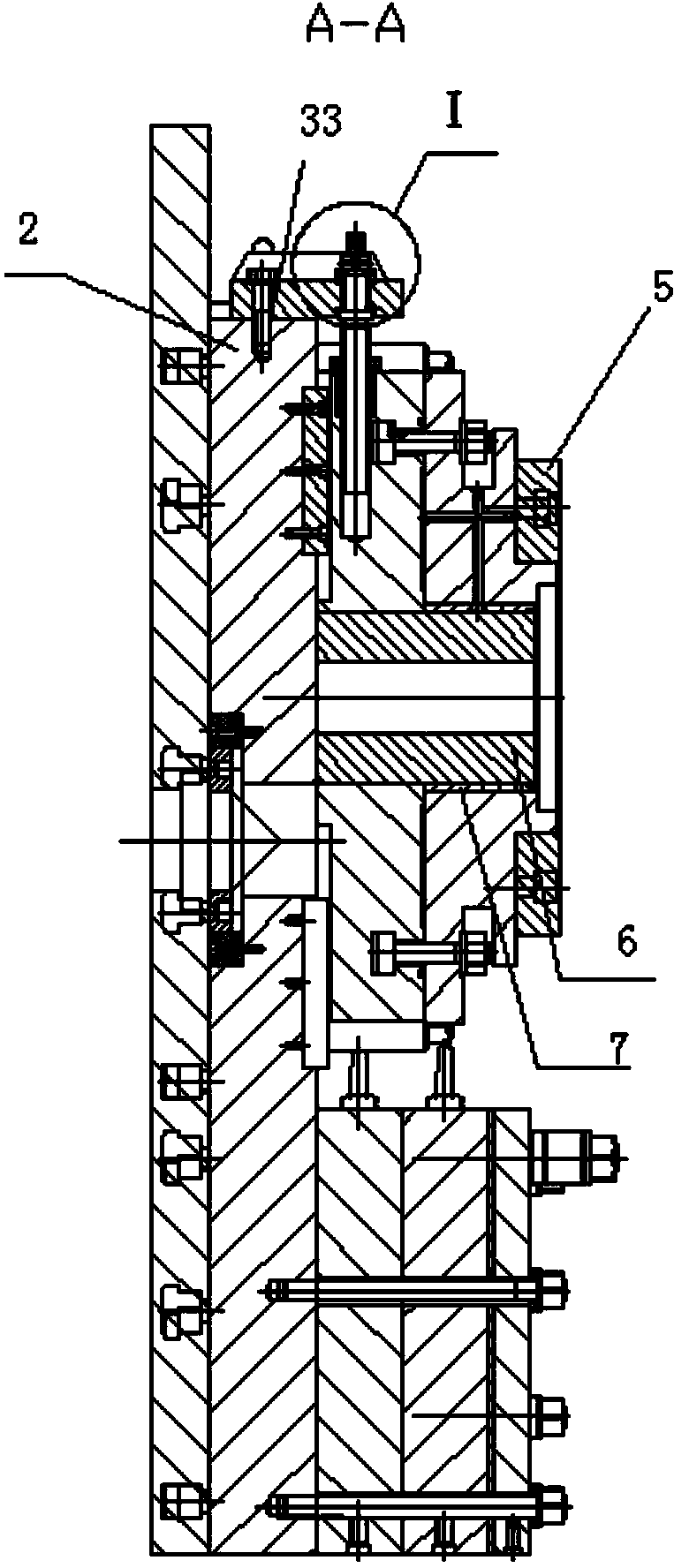

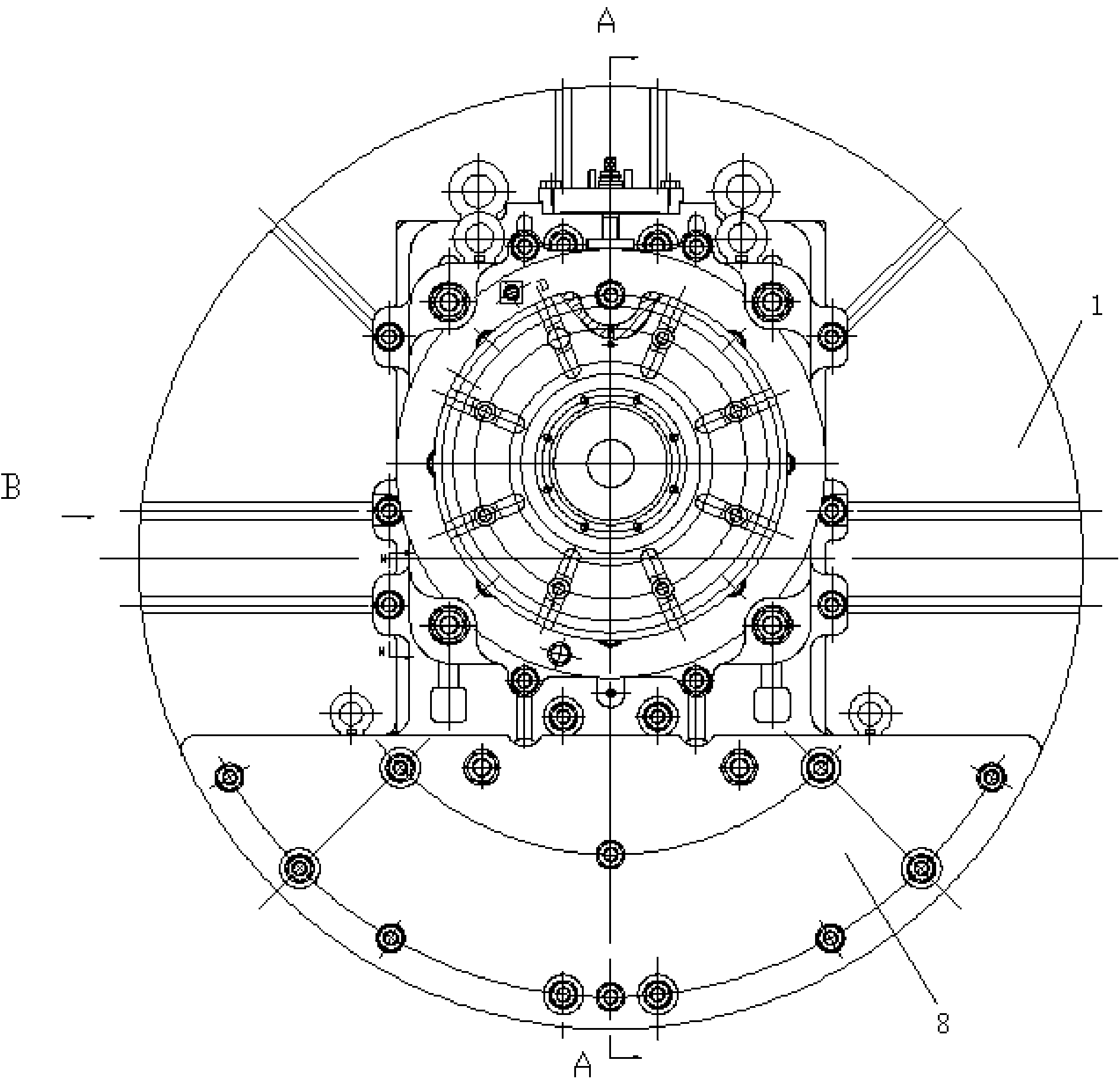

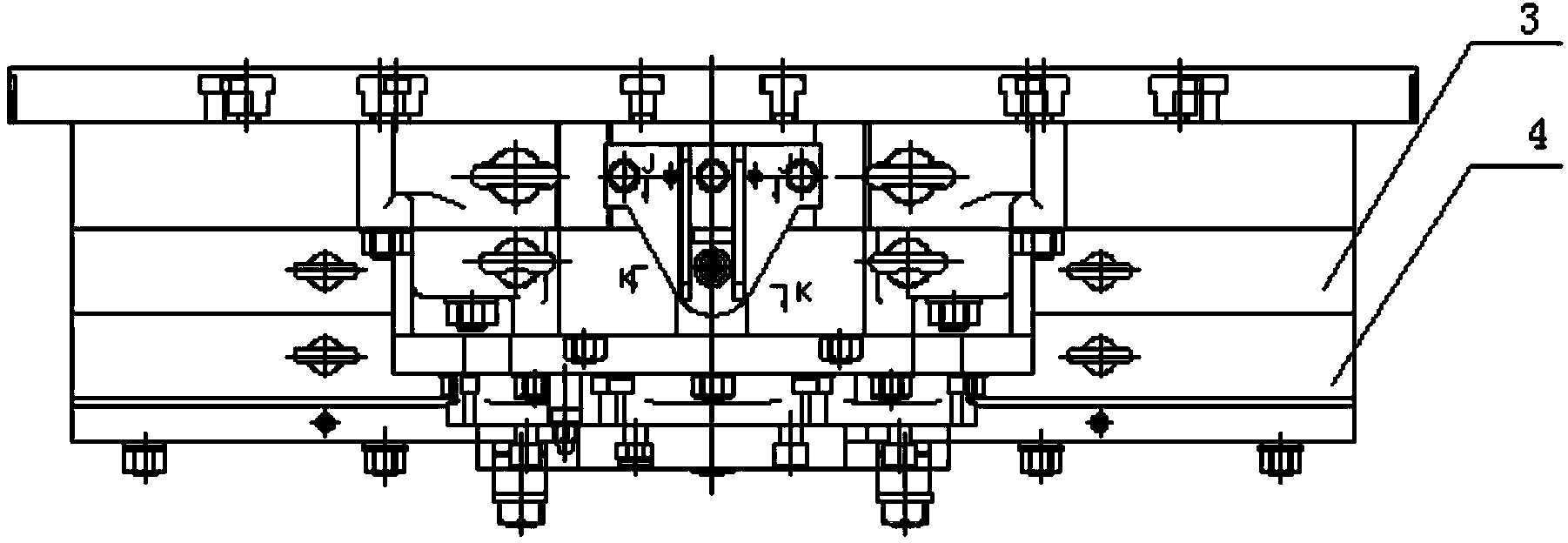

[0036] Such as Figure 1-8 As shown, a crankshaft eccentric tooling, the tooling includes a lathe face plate 1 with a split structure, a head ax disc 2, an adjustment eccentric assembly, a workpiece connection assembly, an eccentric positioning assembly, and a balance plate assembly. The head ax disc 2 Fixed on the faceplate 1 of the lathe, the adjustment eccentric assembly, the workpiece connection assembly and the eccentric positioning assembly constitute the part of the tooling used to adjust the eccentricity of the crankshaft through the connecting parts, and are fixed on the head ax disk 2 side, the described The balance plate assembly is fixed on the other side of the head ax disk 2. The head ax disk 2 is fixed on the lathe faceplate 1 through T-shaped nuts 17, bolts and special thickened nuts a20. The workpiece connection assembly includes a head portion degree circular bottom plate 3, a head portion degree face plate 4, and a workpiece flange transition plate 5 connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com