Mechanical air pressure expanding shaft used for winding and unwinding system on papermaking and printing packaging equipment

A technology of printing, packaging and pneumatic shaft, which is applied in the field of food machinery, can solve the problems of small gap between the expansion mandrel and the outer tube, cannot fully meet the production requirements, and cannot meet the production requirements, etc., and achieves compact structure and deformation resistance Strong, high-precision effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

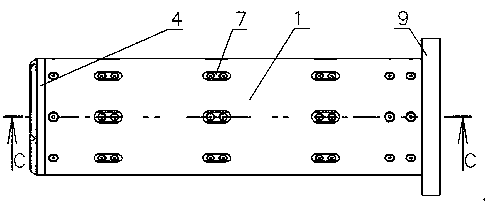

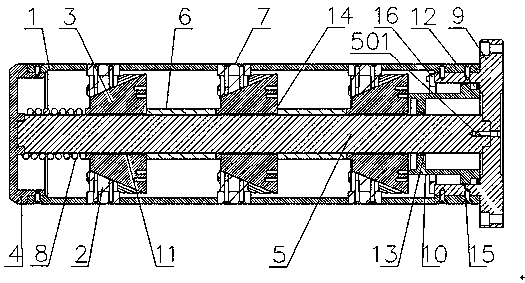

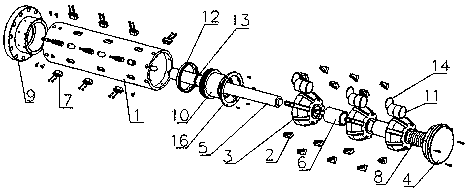

[0025] Such as Figure 1-8 As shown in , a mechanical pneumatic shaft expansion shaft used in papermaking and printing and packaging equipment for winding and unwinding systems includes a mandrel 5, and the boss at one end of the mandrel 5 is inserted into the circular groove of the flange 9, The outer casing of the flange 9 is connected to one end of the shaft tube 1, the inner casing of the flange 9 is fitted with a thrust piston 10, the thrust piston 10 is fitted with a sealing cover 16, and is fixed to the end of the flange 9 by bolts, and the thrust piston 10 is also provided with a guide belt 15 at the contact point with the inner wall of the tube platform of the flange 9, and a plurality of flower discs 3 are sequentially socketed on the mandrel 5 through the oiling copper sleeve 11, and spacers 6 are sleeved on the mandrel 5 between the flower discs 3, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com