Vehicle lathe rough machining tool for upper rocker arm of vertical milled large-scale key part

A kind of tooling and large-scale technology, applied in the field of processing tooling, can solve the problems of heavy rocker arm weight, etc., achieve the effects of reducing workload, saving electricity costs and labor costs, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described below in conjunction with accompanying drawing.

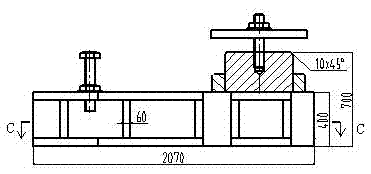

[0026] Such as figure 2 with Figure 4 Shown, the present invention comprises the frock base 8 parallel to the faceplate surface of the vertical car, and the frock base 8 includes upper and lower two-layer parallel seat plates and a support plate connecting the two. One end of the frock base 8 is respectively provided with a frock claw clamping place 9 in four directions, which is used for clamping and fixing the frock base 8 by the claws in the center of the flower plate.

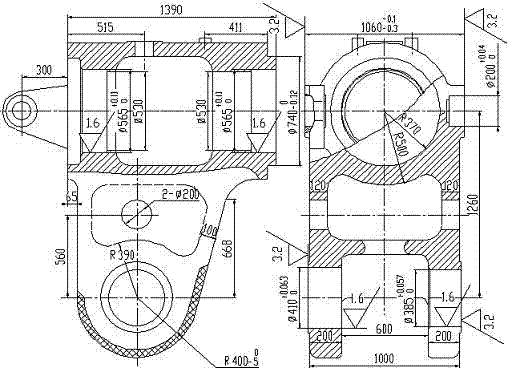

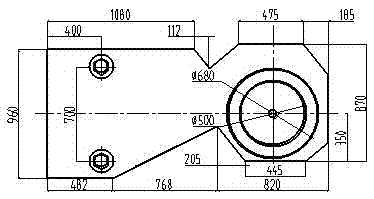

[0027] Such as figure 2 with image 3 As shown, the tooling base 8 is connected with a shaft hole positioning block 4 on the top surface of the above-mentioned end, and the shaft hole positioning block 4 is also covered with a replaceable shaft hole positioning ring 5, both of which are used to extend into the upper rocker arm 1. in the shaft hole, and the first step at the entrance of the shaft h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com